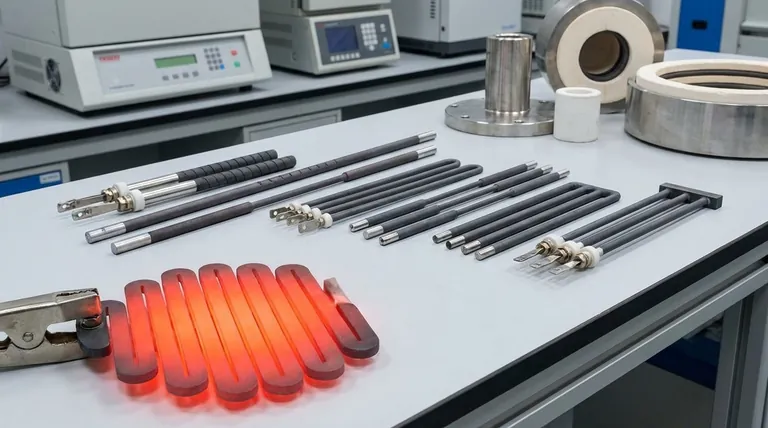

At their core, silicon carbide (SiC) heating elements are available in three primary configurations: simple straight rods, U-shaped multi-leg elements, and W-shaped multi-leg elements. These designs often incorporate single or double spiral cuts to optimize the resistance and heat distribution along the element's active length. The choice of design is not arbitrary; it is driven entirely by the specific requirements of the furnace or heating application, such as mounting orientation and the need for uniform heat density.

The physical design of a silicon carbide heating element—whether a straight rod, U-type, or W-type—is a direct solution to a specific engineering challenge, primarily furnace geometry, terminal access, and the required uniformity of the heated zone.

The Fundamental Building Block: The Rod Element

Straight Rod Design

The most basic design is the straight SiC rod. These elements have two terminals, one at each end, and require electrical connections to be made on opposite sides of the furnace or heating chamber.

They are often manufactured with a spiral groove cut into the "hot zone" to increase electrical resistance and concentrate heat generation in that specific area. The ends, or "cold ends," are left solid with lower resistance to minimize heat near the terminals and power connections.

Multi-Leg Designs for Specific Applications

When furnace design prohibits access to both sides for connections, or when specific heating patterns are required, multi-leg elements are used.

The U-Type Element

The U-type element is essentially two SiC rods joined at the bottom with a bridge, forming a "U" shape. This design allows both electrical terminals to be on the same side, simplifying wiring and furnace construction significantly.

U-type elements are highly versatile, as they can be mounted either vertically, hanging from the top, or horizontally, supported from a furnace wall.

The W-Type Element

The W-type element consists of three SiC rods connected at one end, forming a "W" configuration. This design also provides single-sided connection access.

Its primary application is for horizontal installation in applications requiring highly uniform heating over a large surface area, such as in float glass production furnaces.

The SCR-Type Element

The SCR-type is an enhanced version of the U-shaped element. It is engineered to provide superior temperature control and greater energy efficiency. This makes it a preferred choice for technically demanding processes where precise thermal management is critical.

Understanding the Trade-offs

Choosing a design requires balancing installation logistics, performance requirements, and cost. There is no single "best" element, only the most appropriate one for the job.

Installation and Mounting Constraints

Straight rods are simple but require terminal access on both sides of the furnace. The U-type offers the most flexibility, suitable for both vertical and horizontal mounting with single-side access. The W-type is specifically designed for horizontal use and may not be suitable for other orientations.

Connection and Wiring Complexity

Multi-leg elements (U, W, and SCR) are designed explicitly to simplify wiring by consolidating terminals. This can be a critical advantage in large or complex furnace designs, reducing installation time and potential points of failure.

Custom vs. Standard Designs

While standard shapes cover most needs, nearly all SiC elements can be custom-made. If you have a unique furnace geometry or highly specific heating requirement, a custom design may be the only viable solution, though it will impact cost and lead time.

Making the Right Choice for Your Goal

To select the correct element, you must first define your primary constraint or goal. The required physical dimensions—such as heated length (L1), terminal length (L2), and diameters (d, D)—must be specified for any type.

- If your primary focus is simple replacement in a standard furnace: A straight rod is the most common and cost-effective starting point.

- If your primary focus is single-side terminal access or mounting flexibility: The U-type element is the most versatile and practical choice.

- If your primary focus is uniform heat in a wide, horizontal chamber: The W-type element is specifically engineered for this exact purpose.

- If your primary focus is maximum energy efficiency and precise control: The SCR-type element offers enhanced performance for demanding applications.

Ultimately, aligning the element's design characteristics with the operational demands of your thermal process is the key to a successful system.

Summary Table:

| Design Type | Key Features | Common Applications |

|---|---|---|

| Straight Rod | Simple, two terminals, spiral cuts for heat concentration | Standard furnace replacements, basic heating setups |

| U-Type | Single-side access, versatile mounting (vertical/horizontal) | Furnaces with limited terminal access, flexible installations |

| W-Type | Single-side access, uniform heating over large areas | Horizontal furnaces, e.g., float glass production |

| SCR-Type | Enhanced U-type, superior temperature control and energy efficiency | Technically demanding processes requiring precise thermal management |

Struggling to choose the right silicon carbide heating element for your furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether you need standard or custom-designed elements for optimal performance. Contact us today to discuss your specific needs and enhance your thermal process efficiency!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat