In practice, vacuum carburizing is most often applied to high-performance mechanical components where failure is not an option. These typically include critical parts such as transmission gears, various types of shafts, engine fuel injectors, bearings, and bushings that demand superior surface hardness combined with a tough, resilient core.

The decision to use vacuum carburizing is driven by the performance demands placed upon the component. This process is ideal for parts requiring extreme surface hardness for wear resistance while needing a softer, shock-absorbing core to prevent fractures under high stress.

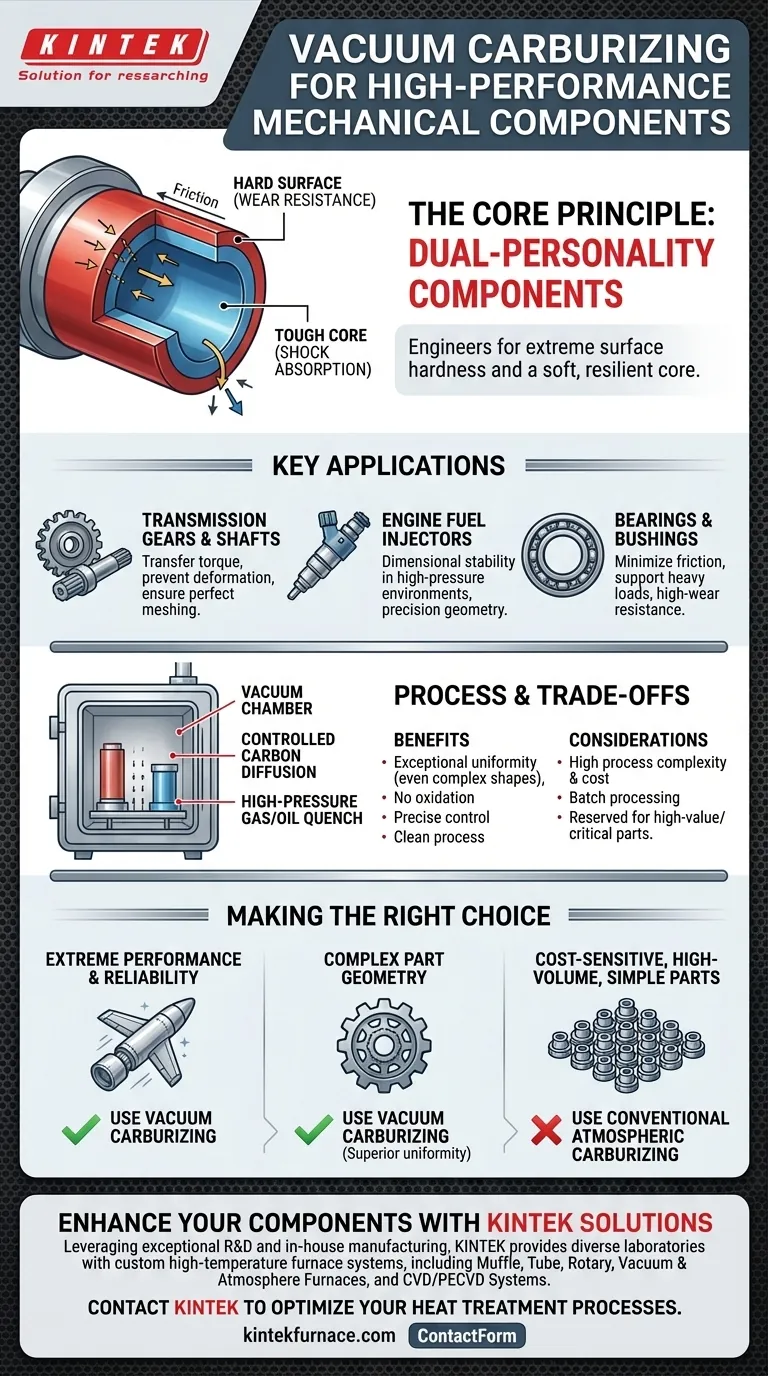

The Core Principle: Creating a "Dual-Personality" Component

The components selected for vacuum carburizing share a common need: they must withstand two different types of stress simultaneously. The process fundamentally alters the steel to meet this challenge.

The Need for a Hard, Wear-Resistant Surface

Parts like gears and bearings are subjected to constant friction, rubbing, and contact stress. Without a hardened surface, they would wear down and fail quickly.

Vacuum carburizing solves this by diffusing carbon into the surface of the steel in a highly controlled vacuum environment. This creates a hard, carbon-rich layer, or "case," that provides exceptional wear and fatigue resistance.

The Importance of a Tough, Ductile Core

The same components often endure significant torque, impact, and bending forces. A part that is hard all the way through would be brittle and prone to shattering under sudden loads.

By leaving the component's core untreated, it retains its original softer, more ductile properties. This tough core can absorb shock and distribute stress, preventing catastrophic fractures from starting and propagating through the part.

A Closer Look at Common Applications

Understanding the function of these components clarifies why vacuum carburizing is the preferred method.

Drivetrain and Transmission Components

Gears and shafts must transfer immense torque without deforming or wearing at the contact points.

The hard case ensures the gear teeth mesh perfectly over millions of cycles, while the soft core allows the shaft to flex slightly under load without snapping.

Engine and Fuel System Parts

Components like engine fuel injectors require dimensional stability and resistance to the harsh, high-pressure environment inside an engine.

Vacuum carburizing provides a uniform case that doesn't distort the part's intricate geometry, ensuring precision and long service life.

Bearings and Bushings

These parts are the definition of a high-wear application. They facilitate motion between other components under heavy loads.

The process creates an extremely hard and smooth surface that minimizes friction, while the core supports the load without cracking.

Understanding the Trade-offs and Considerations

While powerful, vacuum carburizing is a specialized process with specific trade-offs. It is not the solution for every heat treatment need.

Process Complexity and Cost

Vacuum furnaces are sophisticated and expensive to acquire and operate. The use of vacuum pumps and precise gas control systems means this process is typically reserved for high-value or mission-critical parts where the added cost is justified by performance.

Batch Processing and Geometry

Vacuum carburizing is a batch process, meaning parts are loaded into a chamber for treatment. This method provides exceptional uniformity, even on parts with complex shapes, holes, or blind features where traditional gas carburizing might struggle.

Material and Quenching Method

The process is specifically for steels capable of absorbing carbon. After the carburizing cycles, parts are quenched using either high-pressure gas (HPGQ) or oil to lock in the hardened structure. The choice of quench depends on the steel grade and the desired final properties.

Making the Right Choice for Your Application

Selecting the right heat treatment is a critical engineering decision. Use the following guidelines to determine if vacuum carburizing fits your goal.

- If your primary focus is extreme performance and reliability: Use vacuum carburizing for critical components where failure would be catastrophic, such as in aerospace or high-performance automotive applications.

- If your primary focus is achieving a uniform case on complex part geometry: The low-pressure environment ensures carbon reaches all surfaces evenly, making it superior for intricate parts.

- If your primary focus is cost-sensitive, high-volume production of simple parts: A conventional atmospheric carburizing process may be a more economical and faster alternative.

By understanding the unique properties it imparts, you can strategically apply vacuum carburizing to engineer components that are exceptionally durable and resilient.

Summary Table:

| Component Type | Key Benefits |

|---|---|

| Transmission Gears | Hard surface for wear resistance, tough core for shock absorption |

| Shafts | Prevents deformation and snapping under torque |

| Engine Fuel Injectors | Dimensional stability in high-pressure environments |

| Bearings and Bushings | Minimizes friction with a hard, smooth surface |

| Bushings | Supports heavy loads without cracking |

Enhance your high-performance components with KINTEK's advanced vacuum carburizing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with custom high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs for superior durability and reliability. Contact us today to discuss how we can optimize your heat treatment processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control