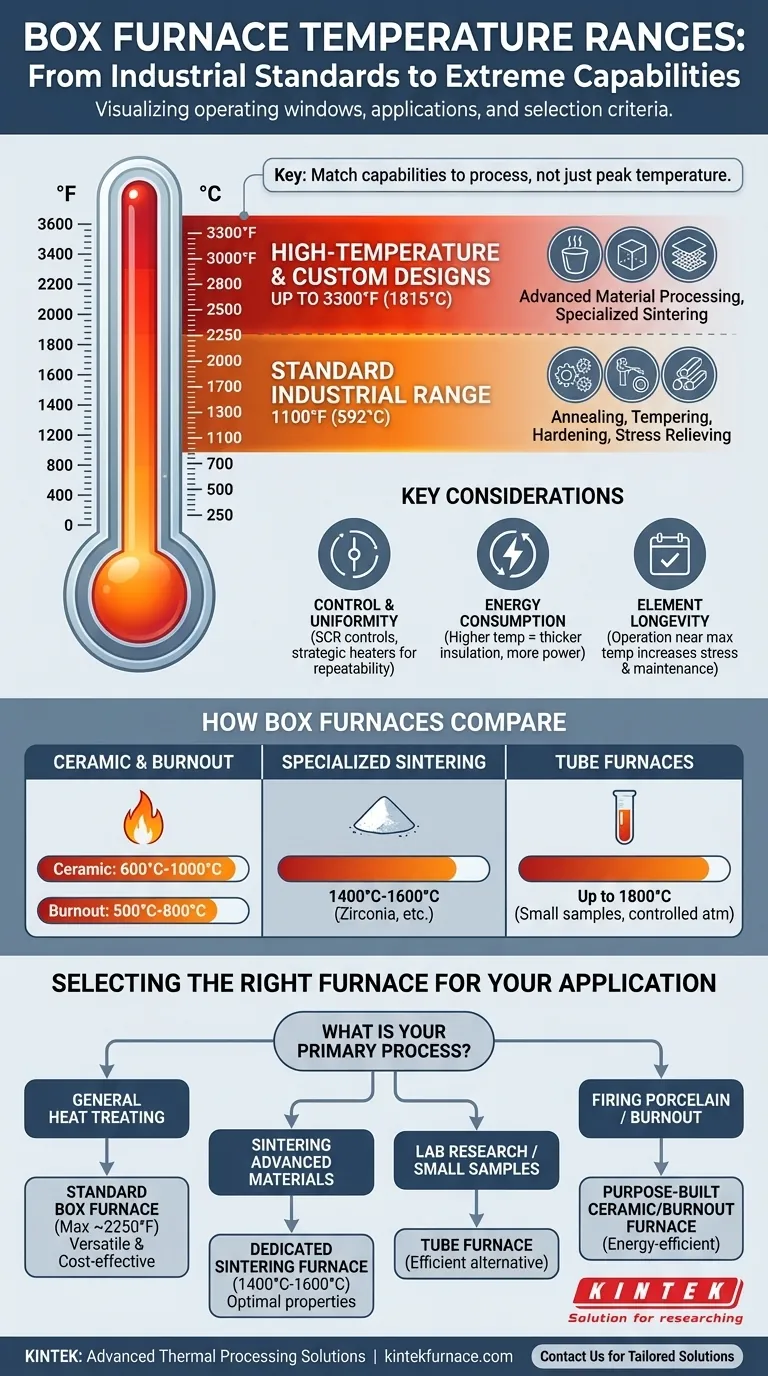

In simple terms, a standard industrial box furnace operates at temperatures ranging from over 1100°F (592°C) up to 2250°F (1232°C). However, this range can be extended significantly, with highly specialized and custom-designed models capable of reaching extreme temperatures up to 3300°F (1815°C) for advanced material processing.

A box furnace's temperature range is a function of its design and intended application. The key is to match the furnace's capabilities—not just its peak temperature—to the specific thermal process you need to perform.

Deconstructing the Temperature Range

Understanding what defines a box furnace's operating temperature helps you evaluate its suitability for your task. The range is not arbitrary; it is determined by the furnace's construction and control systems.

The Standard Operating Window

The most common box furnaces are designed to operate between 1100°F (592°C) and 2250°F (1232°C). This window covers a vast number of industrial heat-treating applications, including annealing, tempering, hardening, and stress relieving for various metals.

High-Temperature and Custom Designs

Furnaces that operate above 2250°F are considered high-temperature models. Reaching up to 3300°F (1815°C) requires specialized heating elements, advanced refractory insulation, and more sophisticated construction to handle the thermal stress and ensure energy efficiency.

The Importance of Control and Uniformity

Peak temperature is only one part of the equation. A high-quality furnace provides precise temperature control and uniformity. Features like SCR (Silicon Controlled Rectifier) power controls and strategically arranged heaters ensure that the entire chamber maintains a balanced temperature field, which is critical for process repeatability.

How Box Furnaces Compare to Other Furnace Types

A box furnace is a versatile tool, but it's not always the optimal choice. Its general-purpose nature means other, more specialized furnaces may be better suited for certain tasks.

For Lower Temperature Ceramic and Burnout Processes

Ceramic firing furnaces typically operate between 600°C and 1000°C. Similarly, burnout furnaces used for investment casting run at moderate temperatures from 500°C to 800°C to remove wax without damaging the mold. Using a high-temperature box furnace for these tasks would be highly inefficient.

For Specialized Sintering and Pressing

Sintering furnaces are built to process materials like zirconia at very high temperatures, typically between 1400°C and 1600°C, to achieve densification. While some high-end box furnaces can reach this range, dedicated sintering furnaces are optimized for this specific process.

The Tube Furnace Alternative

Tube furnaces can match the temperature ranges of box furnaces (up to 1800°C) but are designed for processing smaller samples, often in a tightly controlled atmosphere. Their geometry makes them ideal for laboratory experiments or continuous-flow applications.

Understanding the Trade-offs

Selecting a furnace with a higher temperature capability involves clear engineering and financial trade-offs.

Energy Consumption and Insulation

Higher temperatures demand exponentially more energy. A furnace rated for 3300°F requires significantly thicker, higher-grade insulation and more robust power systems than a standard 2250°F model. This directly impacts both the initial purchase price and long-term operating costs.

Heating Element Longevity

Operating a furnace consistently near its maximum rated temperature puts immense stress on the heating elements. This can reduce their operational lifespan and increase maintenance frequency and cost.

Versatility vs. Specialization

A high-temperature, general-purpose box furnace offers excellent versatility. However, a specialized furnace designed for a single task—like sintering or burnout—will almost always perform that task more efficiently and with better results.

Selecting the Right Furnace for Your Application

Your final choice should be driven by your specific process goals, not just a desire for the highest possible temperature.

- If your primary focus is general heat treating (annealing, tempering): A standard box furnace with a maximum temperature around 2250°F (1232°C) is the most versatile and cost-effective choice.

- If your primary focus is sintering advanced materials like zirconia: A dedicated sintering furnace operating in the 1400°C to 1600°C range is required for optimal material properties.

- If your primary focus is lab research with small samples or controlled atmospheres: A tube furnace is likely a more efficient and suitable alternative to a large box furnace.

- If your primary focus is firing porcelain or investment casting burnout: A purpose-built, lower-temperature ceramic or burnout furnace will be far more energy-efficient.

Ultimately, defining your precise process requirements is the most critical step in selecting a furnace that will deliver consistent, reliable results.

Summary Table:

| Temperature Range | Common Applications | Key Considerations |

|---|---|---|

| 1100°F - 2250°F | Annealing, tempering, hardening | Versatile, cost-effective for general heat treating |

| Up to 3300°F | Advanced material processing | Requires specialized elements, higher energy use |

Need a high-temperature furnace tailored to your lab's unique requirements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise performance for your experiments. Contact us today to discuss how we can enhance your thermal processing efficiency and results!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis