In practice, Molybdenum disilicide (MoSi2) heating elements are designed for furnace operating temperatures between approximately 1600°C and 1800°C (2912°F - 3272°F). This is possible because the element's own surface temperature can safely reach up to 1900°C (3452°F), allowing it to effectively heat the surrounding furnace chamber to a slightly lower, stable working temperature.

The key to understanding MoSi2 elements is not just their maximum temperature, but the distinction between the element's surface temperature and the furnace's achievable chamber temperature. This difference is critical for proper furnace design and operation, as MoSi2's unique properties make it ideal for specific high-temperature, oxidizing environments.

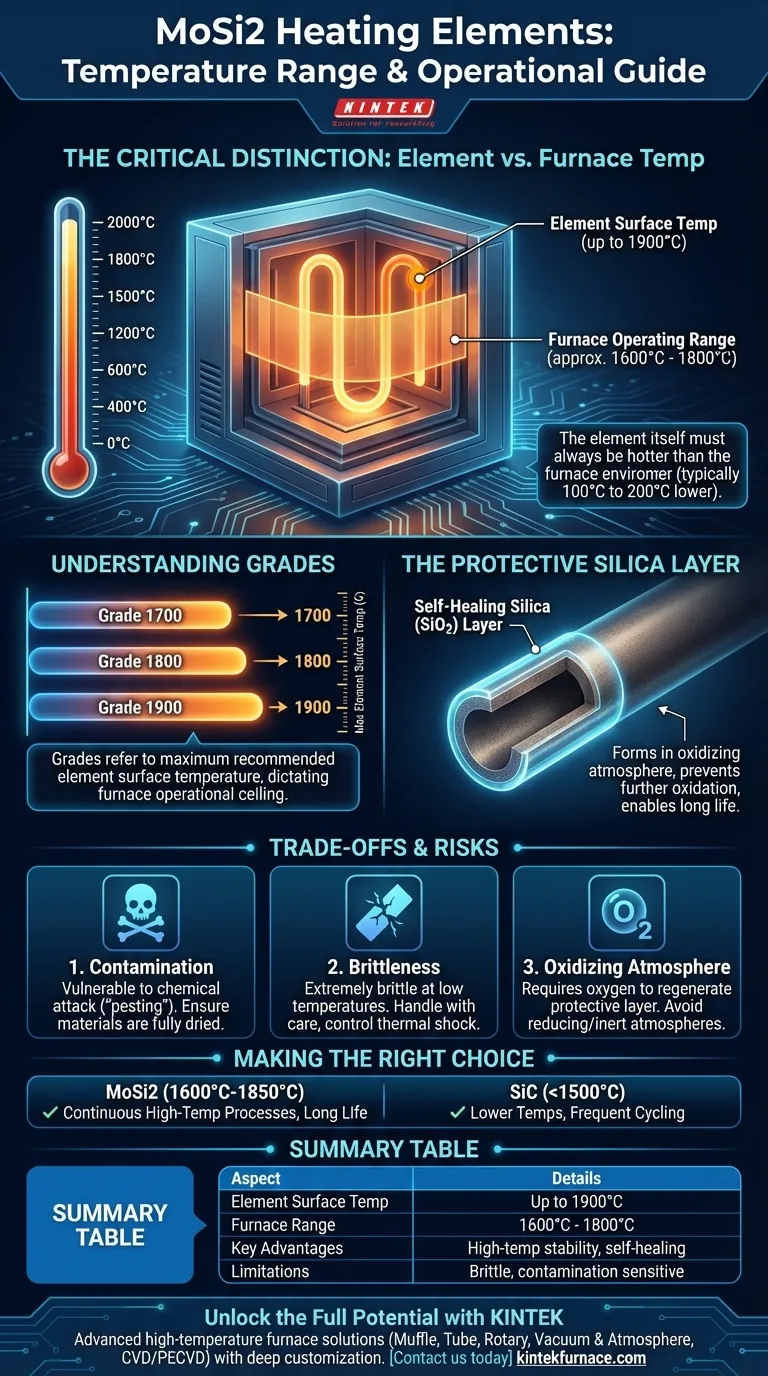

The Critical Distinction: Element vs. Furnace Temperature

Choosing a heating element requires understanding that the element itself must always be hotter than the environment it is heating. MoSi2 elements are graded by their maximum recommended temperature, which dictates the furnace's operational ceiling.

How MoSi2 Grades Correlate to Temperature

MoSi2 elements are often sold in grades, such as "1700," "1800," or "1900." These numbers refer to the maximum recommended element surface temperature in degrees Celsius.

For example, a "Grade 1800" element is designed to operate with a surface temperature up to 1800°C.

Practical Furnace Operating Range

This high element temperature allows the furnace chamber to reliably maintain a working temperature that is typically 100°C to 200°C lower.

A furnace using Grade 1800 elements can typically operate continuously around 1700°C, while one with Grade 1900 elements might reach 1800°C for specialized processes.

The Protective Silica Layer

MoSi2's high-temperature capability is due to the formation of a thin, self-healing layer of silica (SiO2) on its surface when heated in an oxidizing atmosphere.

This glassy layer acts as a barrier, preventing further oxidation of the underlying material and enabling a long service life at extreme temperatures.

Understanding the Trade-offs and Risks

While MoSi2 elements offer exceptional performance at high temperatures, they come with specific vulnerabilities and operational requirements that are crucial to understand.

Vulnerability to Contamination

These elements are highly susceptible to chemical attack, a phenomenon often called "pesting." Technicians must ensure materials, like colored or painted zirconia, are fully dried before heating.

Failure to follow proper protocols can release contaminants that degrade the element's protective silica layer, leading to premature failure.

Brittleness at Room Temperature

MoSi2 is a ceramic material and is extremely brittle at low temperatures. The elements must be handled with great care during installation and maintenance to avoid fractures.

They are also sensitive to severe thermal shock, requiring controlled heating and cooling ramps to prevent cracking.

The Need for an Oxidizing Atmosphere

The protective silica layer can only form and regenerate in the presence of oxygen. Using MoSi2 elements in reducing or inert atmospheres without proper shielding will lead to rapid degradation and failure.

Making the Right Choice for Your Application

Selecting the correct heating element technology is a trade-off between maximum temperature, operational environment, and cost.

- If your primary focus is achieving furnace temperatures of 1600°C to 1850°C for continuous processes: Molybdenum disilicide (MoSi2) is the superior choice due to its high-temperature stability and long life.

- If your process operates primarily below 1500°C or involves frequent cycling: Silicon Carbide (SiC) elements may offer a more robust and cost-effective solution.

- If you are maintaining a MoSi2 furnace: Prioritize strict operational protocols for drying materials and controlling ramp rates to prevent contamination and thermal shock.

Understanding these operational requirements is the key to maximizing both the performance and the lifespan of your high-temperature heating system.

Summary Table:

| Aspect | Details |

|---|---|

| Element Surface Temperature | Up to 1900°C (e.g., Grade 1800 for 1800°C) |

| Furnace Operating Range | 1600°C to 1800°C (typically 100-200°C lower than element) |

| Key Advantages | High-temperature stability, self-healing silica layer, ideal for oxidizing atmospheres |

| Limitations | Brittle at room temperature, sensitive to contamination and thermal shock |

Unlock the Full Potential of Your High-Temperature Applications with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you need precise temperature control up to 1800°C or tailored systems for specialized processes, we deliver reliable, long-lasting performance. Contact us today to discuss how our MoSi2 heating elements and furnace solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do thick film heating elements differ from other types? Discover Speed, Precision, and Efficiency

- What are the characteristics and common uses of metal resistance heating elements? Discover Key Materials for Efficient Heat

- What applications are ceramic heating elements particularly suited for? Ideal for High-Temp, Corrosive, and Sensitive Environments

- Why are high-precision stainless steel thermocouples and handheld readers required to characterize the temperature field of a tube furnace?

- What is the density of MoSi2 heating elements? Understand the Key to High-Temp Performance

- What is the maximum operating temperature for MoSi2 heating elements? Achieve Reliable High-Temp Performance

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision

- What is the maximum temperature of a heating element? Balancing Material Limits, Atmosphere & Design