To properly process zirconia, you need a dedicated high-temperature sintering furnace, not a standard porcelain furnace. These specialized units are engineered to reach the extreme temperatures required for densification (up to 1600°C) and use specific components to prevent contamination, ensuring the final restoration achieves its designed strength and aesthetic properties.

The core challenge with zirconia is not just getting it hot, but achieving and holding extremely high, uniform, and clean heat in a precisely controlled cycle. A specialized zirconia sintering furnace is the only tool designed to meet all of these non-negotiable requirements.

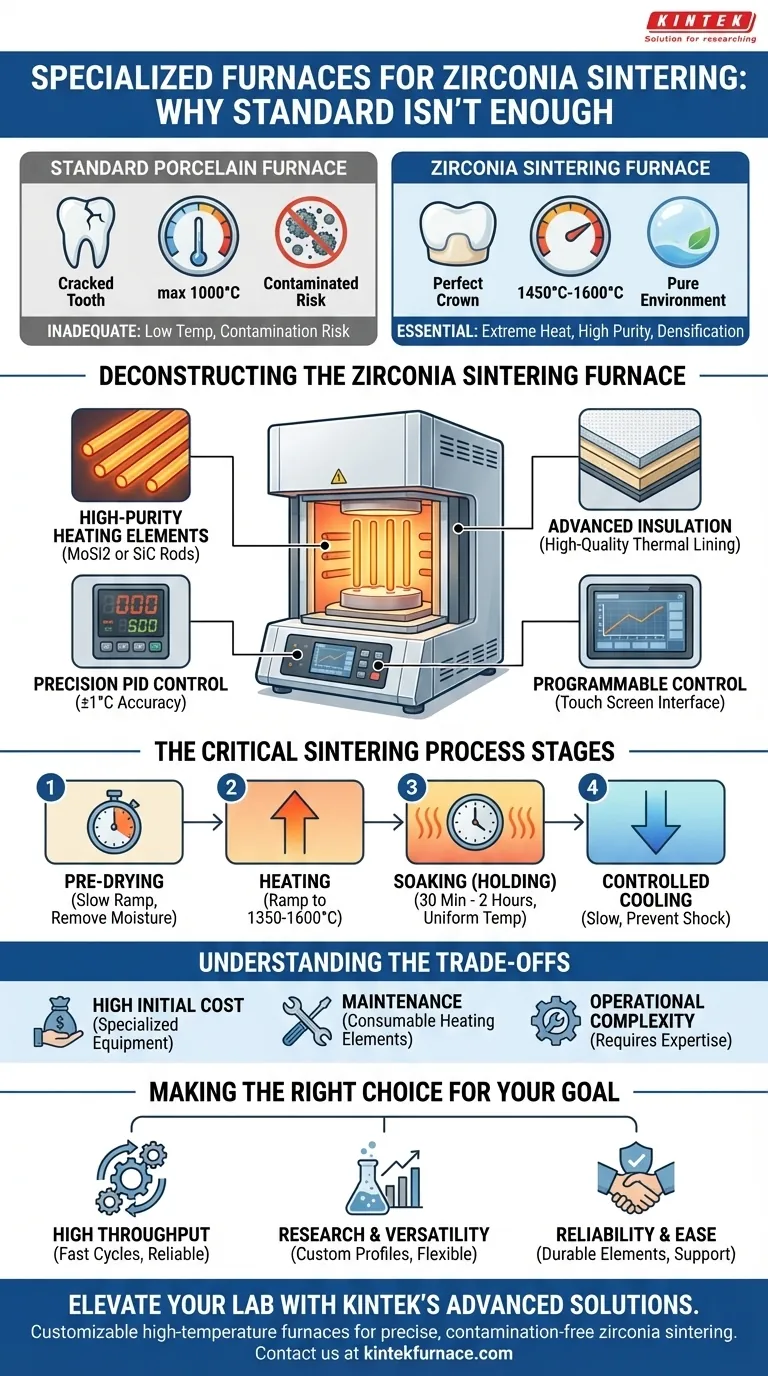

Why a Standard Porcelain Furnace Isn't Enough

The fundamental difference lies in temperature capability and material purity. A standard porcelain furnace simply cannot meet the demands of zirconia.

The Temperature Gap

A typical porcelain furnace operates at much lower temperatures, usually below 1000°C. Zirconia requires a sintering temperature between 1450°C and 1600°C to achieve full densification and transform from its soft, chalky state to a high-strength ceramic.

The Risk of Contamination

Zirconia sintering demands an exceptionally clean environment. The heating elements in standard furnaces can release particles that contaminate the zirconia, leading to discoloration and a significant reduction in structural integrity.

Deconstructing the Zirconia Sintering Furnace

A zirconia sintering furnace is a purpose-built machine with several key components that differentiate it from other dental furnaces.

High-Purity Heating Elements

These are the heart of the furnace. The most common types are molybdenum disilicide (MoSi2) or silicon carbide (SiC) rods. These materials are chosen because they can withstand extreme temperatures without degrading or releasing contaminants that would compromise the zirconia. Silicon carbide is often preferred for its chemical compatibility and long-term durability.

Precision Temperature Control

Achieving the correct final properties in zirconia requires exact temperature management. These furnaces use a sophisticated Proportional-Integral-Derivative (PID) control system paired with thermocouples to regulate heat with incredible accuracy, often to within ±1°C. This ensures the material moves through its heating and cooling cycles perfectly.

Advanced Insulation and Chamber Design

To efficiently reach and maintain 1600°C, the furnace chamber is lined with high-quality, green thermal insulation materials. This minimizes heat loss, ensures uniform temperature distribution, and reduces energy consumption.

Programmable Control and Automation

Modern zirconia furnaces feature user-friendly interfaces, often with a color touch screen. They allow technicians to use pre-set programs for specific materials or create custom multi-stage firing profiles for research or unique cases. Features like a power interruption memory, which resumes a cycle after an outage, are critical for long sintering programs.

The Critical Sintering Process Stages

The furnace's programmability is essential for executing the precise, multi-stage process required for successful sintering.

Stage 1: Pre-Drying

The cycle begins with a slow, low-temperature ramp-up to gently remove any residual moisture from the restoration. Rushing this step can cause cracks.

Stage 2: Heating

The furnace then ramps up to the target sintering temperature, typically between 1350°C and 1600°C, depending on the specific zirconia material.

Stage 3: Soaking (Holding)

The furnace holds at the peak temperature for a set duration, often from 30 minutes to 2 hours. This "soaking" phase ensures that the entire restoration reaches a uniform temperature for complete and even densification.

Stage 4: Controlled Cooling

This is just as critical as heating. The furnace cools down slowly and precisely to prevent thermal shock, which can cause warping or catastrophic fractures in the newly hardened ceramic.

Understanding the Trade-offs

While essential, investing in a zirconia sintering furnace involves clear trade-offs that every lab or clinic must consider.

High Initial Cost

These are highly specialized pieces of equipment with advanced components. Their purchase price is significantly higher than that of a standard porcelain furnace.

Maintenance and Consumables

The high-purity heating elements that make these furnaces effective have a finite lifespan. They are a consumable component that will need to be replaced periodically, representing an ongoing operational cost.

Operational Complexity

While modern interfaces are user-friendly, understanding the nuances of different zirconia materials and their specific sintering profiles requires training and expertise. Incorrect programming can easily ruin expensive restorations.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on the primary needs of your lab or practice.

- If your primary focus is high throughput and efficiency: Prioritize a furnace with proven "fast sintering" cycles and a reliable power interruption recovery function to protect long runs.

- If your primary focus is material versatility and research: Select a model with a highly flexible and programmable interface that allows you to create and save custom firing profiles.

- If your primary focus is reliability and ease of use: Look for furnaces with durable silicon carbide heating elements, an intuitive user interface, and strong manufacturer support for maintenance and troubleshooting.

Investing in the right sintering furnace is a direct investment in predictable, high-quality, and aesthetic final restorations.

Summary Table:

| Feature | Description |

|---|---|

| Temperature Range | 1450°C to 1600°C for full densification |

| Heating Elements | Molybdenum disilicide (MoSi2) or silicon carbide (SiC) for purity |

| Control System | PID with ±1°C accuracy for precise cycles |

| Key Stages | Pre-drying, heating, soaking (30 min to 2 hours), controlled cooling |

| Primary Use | Sintering zirconia in dental labs and clinics |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Whether you prioritize high throughput, material versatility, or reliability, our furnaces ensure precise, contamination-free sintering for superior zirconia restorations. Contact us today to discuss how we can enhance your workflow and deliver tailored solutions for your success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations