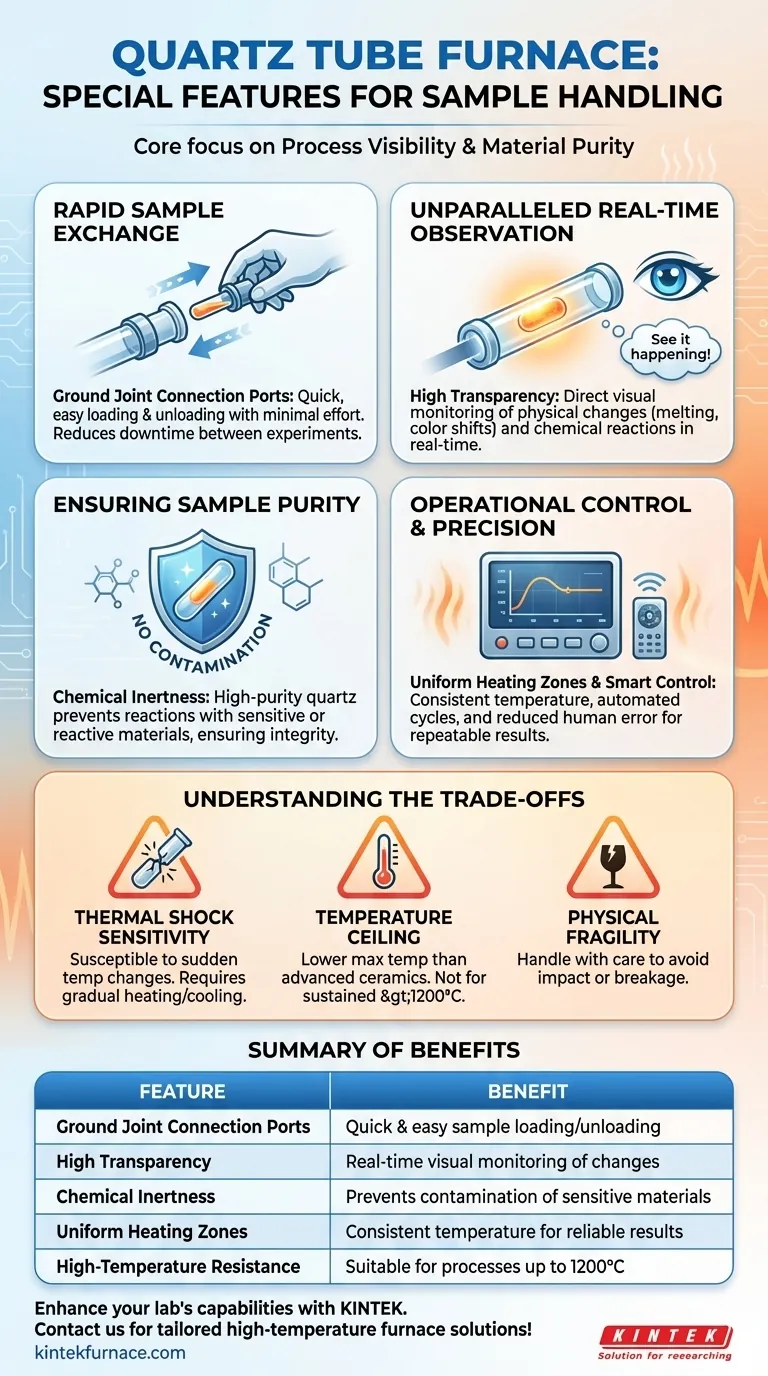

At its core, a quartz tube furnace offers special features for sample handling centered on process visibility and material purity. Design elements like ground joint connection ports allow for quicker and more convenient sample replacement, while the inherent transparency and chemical inertness of the quartz tube itself allow for real-time observation and the processing of reactive materials without contamination.

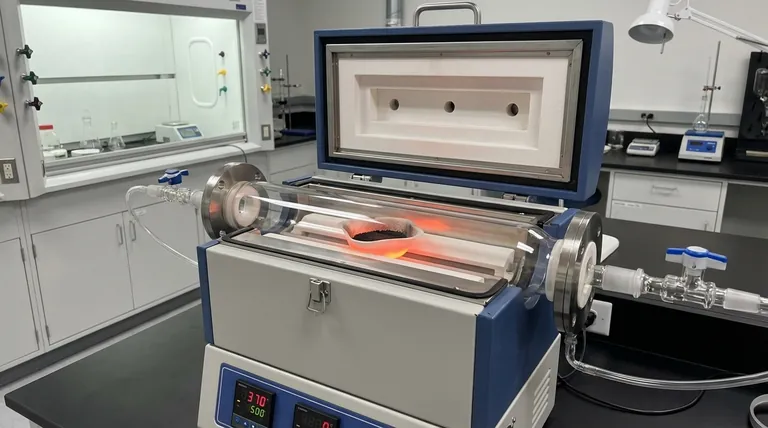

A quartz tube furnace is more than just a heating device; it's an observation window into high-temperature processes. Its design prioritizes not only heating a sample but also seeing, controlling, and preserving the integrity of that sample throughout the experiment.

The Core Advantages for Sample Handling

The unique properties of the quartz material, combined with specific design choices, create a highly controlled and observable environment for your samples.

Designed for Rapid Sample Exchange

Many quartz tube furnaces feature ground joint connection ports. This design allows the end caps or flanges to be sealed, rotated, and removed with minimal effort.

This contrasts with more permanent or complex sealing mechanisms, significantly reducing the time and difficulty involved in loading and unloading samples between experiments.

Unparalleled Real-Time Observation

The most distinct feature of a quartz tube is its high transparency. This allows you to directly and continuously observe the sample as it is heated.

You can monitor physical changes like melting, sintering, color shifts, or the progress of a chemical reaction like pyrolysis in real-time. This visual feedback is impossible in furnaces with opaque ceramic or metal tubes and is invaluable for process development and scientific research.

Ensuring Sample Purity

Quartz is a form of high-purity glass that is chemically inert to a wide range of substances, even at high temperatures.

This means the furnace tube itself will not react with or contaminate your sample. This is critical when working with highly sensitive or reactive materials where purity is paramount.

Operational Control and Process Precision

Modern furnace systems extend beyond the tube itself, offering sophisticated control that directly impacts how a sample is processed.

Precise Environmental Control

These furnaces provide uniform heating zones and are managed by intelligent control systems. This ensures the sample experiences a stable and consistent temperature.

These systems allow for precise temperature regulation and often enable remote monitoring and programming. This simplifies operation, reduces the chance of human error, and allows for repeatable, automated heating cycles.

Versatility Across Applications

The ability of quartz to withstand temperatures often exceeding 1000°C makes these furnaces suitable for a wide array of high-temperature tasks.

Applications range from material synthesis and annealing to pyrolysis experiments and, depending on the furnace's maximum temperature, the melting of certain materials.

Understanding the Trade-offs

While powerful, the choice of a quartz tube comes with specific limitations that must be understood to ensure safe and effective operation.

Sensitivity to Thermal Shock

Like any glass, quartz is susceptible to thermal shock. A sudden, non-uniform change in temperature—such as placing a cold item into a hot tube or uneven cooling—can cause it to crack.

Proper handling requires gradual heating and cooling cycles and careful loading procedures to prevent catastrophic failure of the tube.

Temperature Ceiling

While its heat resistance is excellent, quartz has a lower maximum operating temperature than advanced ceramics like alumina. If your process requires sustained temperatures well above 1200°C, a different tube material may be necessary.

Physical Fragility

Compared to metal or ceramic tubes, quartz is more fragile. It must be handled with care to avoid impacts or mechanical stress that could lead to chipping or breaking, compromising the vacuum or atmospheric seal.

Making the Right Choice for Your Goal

To select the right tool, you must align the furnace's features with your primary experimental objective.

- If your primary focus is visual process monitoring: The transparency of a quartz tube furnace makes it the definitive and superior choice for observing your sample in real-time.

- If your primary focus is sample purity with reactive chemicals: The chemical inertness of quartz provides the non-reactive environment you need to prevent contamination.

- If your primary focus is extreme temperatures (>1200°C) or physical robustness: You should evaluate a furnace with an alumina or other advanced ceramic tube.

Ultimately, choosing a quartz tube furnace is a decision to prioritize visibility and purity in your high-temperature workflow.

Summary Table:

| Feature | Benefit |

|---|---|

| Ground Joint Connection Ports | Quick and easy sample loading/unloading |

| High Transparency | Real-time visual monitoring of sample changes |

| Chemical Inertness | Prevents contamination of sensitive materials |

| Uniform Heating Zones | Consistent temperature for reliable results |

| High-Temperature Resistance | Suitable for processes up to 1200°C |

Ready to enhance your lab's capabilities with a quartz tube furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can ensure superior sample handling, purity, and real-time observation for your research needs!

Visual Guide

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What physical conditions do high-temperature tube furnaces provide for flue gas kinetics? Precision Thermal Simulation

- What role does a tube furnace play in the co-pyrolysis of MIPW and COS? Unlock Precise Thermal Waste Transformation

- What benefits does a quartz tube furnace offer? Achieve Precise Control and Purity in High-Temp Processing

- What is the significance of defining the quartz tube as a heat transfer boundary? Optimize Your Furnace Modeling

- What is the mechanism of a high-temperature furnace in Bi-2223 sintering? Achieve Precision Phase Transformation