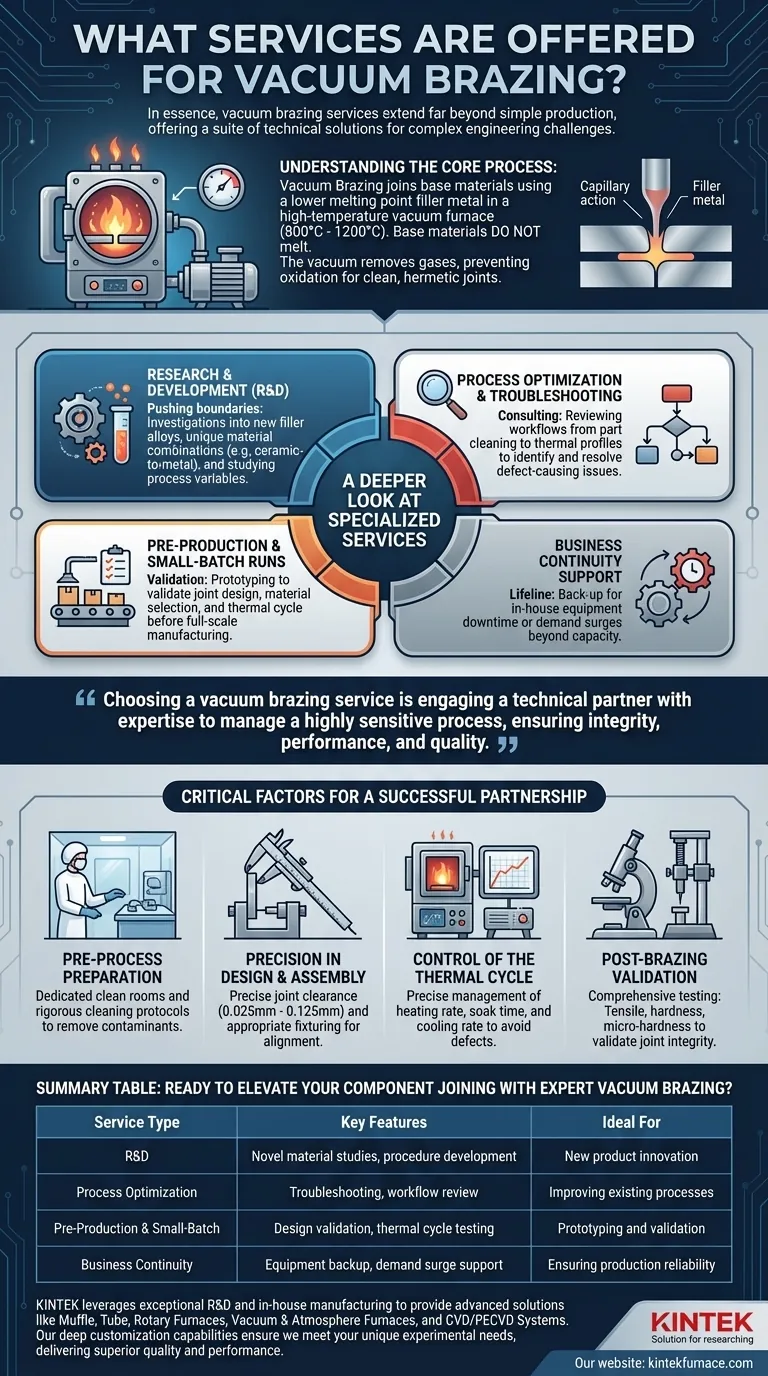

In essence, vacuum brazing services extend far beyond simple production, offering a suite of technical solutions for complex engineering challenges. These services include research and development (R&D) for novel applications, process troubleshooting and optimization, pre-production runs to validate designs, small-batch manufacturing, and business continuity support for when your own equipment is unavailable.

Choosing a vacuum brazing service is not merely about outsourcing a manufacturing step. It's about engaging a technical partner with the expertise to manage a highly sensitive process, ensuring the integrity, performance, and quality of the final joined components.

Understanding the Core Process

Before evaluating services, it is critical to understand the underlying technology. Vacuum brazing is a sophisticated joining method with distinct requirements and advantages.

What is Vacuum Brazing?

Vacuum brazing joins two or more base materials using a filler metal with a lower melting point. The assembly is placed in a high-temperature furnace, heated to melt the filler metal (typically between 800°C and 1200°C), which then flows into the joint via capillary action.

The key is that the base materials never melt, only the filler metal does. This creates a strong, clean, metallurgical bond between the parts.

The Advantage of the Vacuum

Performing this process in a vacuum is the critical factor. The vacuum environment removes atmospheric gases, primarily oxygen, preventing the formation of oxides during the high-temperature cycle.

This results in extremely clean, strong, and hermetically sealed joints with no need for post-braze cleaning, which is often required with other methods.

Key Applications

This technique is ideal for joining dissimilar materials that are difficult or impossible to weld, such as ceramics to metals (like ceramic-to-steel). It is also used for creating complex assemblies in aerospace, medical, and high-performance industrial applications.

A Deeper Look at Specialized Services

A qualified service provider offers more than just access to a furnace. They provide expertise across the entire product lifecycle.

Research & Development (R&D)

This service is for projects pushing the boundaries of material science. It involves investigations into new filler alloys (such as high-entropy alloys), developing procedures for unique material combinations, or studying the effects of process variables like hydrogen partial pressure.

Process Optimization & Troubleshooting

If you have an existing brazing process that yields inconsistent results, a service provider can act as a consultant. They review your entire workflow, from part cleaning to thermal profiles, to identify and resolve issues causing defects.

Pre-Production and Small-Batch Runs

Before committing to expensive tooling and large-scale manufacturing, you can use a service to produce a small batch of parts. This validates the joint design, material selection, and thermal cycle, ensuring the final product will meet performance specifications.

Business Continuity Support

These services provide a critical lifeline when your in-house brazing equipment is down for maintenance or when you experience a temporary surge in demand that exceeds your capacity.

Critical Factors for a Successful Partnership

The quality of a brazed joint depends on meticulous control over numerous variables. A trustworthy partner must demonstrate mastery of these factors.

Pre-Process Preparation

Success begins long before the parts enter the furnace. A top-tier service will have dedicated clean assembly rooms and rigorous protocols for cleaning components to remove any contaminants that could interfere with the bond.

Precision in Design and Assembly

The joint clearance, or the gap between the parts, is paramount. It must be precisely controlled (typically between 0.025 mm and 0.125 mm) to facilitate proper capillary action of the filler metal. The service provider must also use appropriate fixtures and loading tools to maintain alignment during heating.

Control of the Thermal Cycle

The provider must have furnaces capable of precise thermal management. This includes the rate of heating, the time spent at the brazing temperature (soak time), and the rate of cooling. Improper control can lead to distortion, residual stress, or even cracking.

Post-Brazing Validation

A finished part is not a qualified part until it is tested. A comprehensive service includes access to characterization and testing facilities to validate the joint's integrity, including tensile testing, hardness testing, and micro-hardness testing.

Making the Right Choice for Your Project

Selecting a partner requires matching their capabilities to your specific goal.

- If your primary focus is developing a new product: Prioritize a service provider with strong R&D capabilities, a history with novel materials, and comprehensive testing facilities.

- If your primary focus is improving an existing process: Seek a partner who offers in-depth process reviews and troubleshooting, demonstrating a deep understanding of metallurgical principles.

- If your primary focus is outsourcing production or ensuring continuity: Vet the provider's quality systems, especially their controls over cleanliness, assembly, and thermal cycling.

By understanding these technical pillars, you can confidently select a vacuum brazing partner who will ensure the integrity and success of your components.

Summary Table:

| Service Type | Key Features | Ideal For |

|---|---|---|

| R&D | Novel material studies, procedure development | New product innovation |

| Process Optimization | Troubleshooting, workflow review | Improving existing processes |

| Pre-Production & Small-Batch | Design validation, thermal cycle testing | Prototyping and validation |

| Business Continuity | Equipment backup, demand surge support | Ensuring production reliability |

Ready to elevate your component joining with expert vacuum brazing? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs, delivering superior quality and performance. Contact us today to discuss how we can support your project!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures