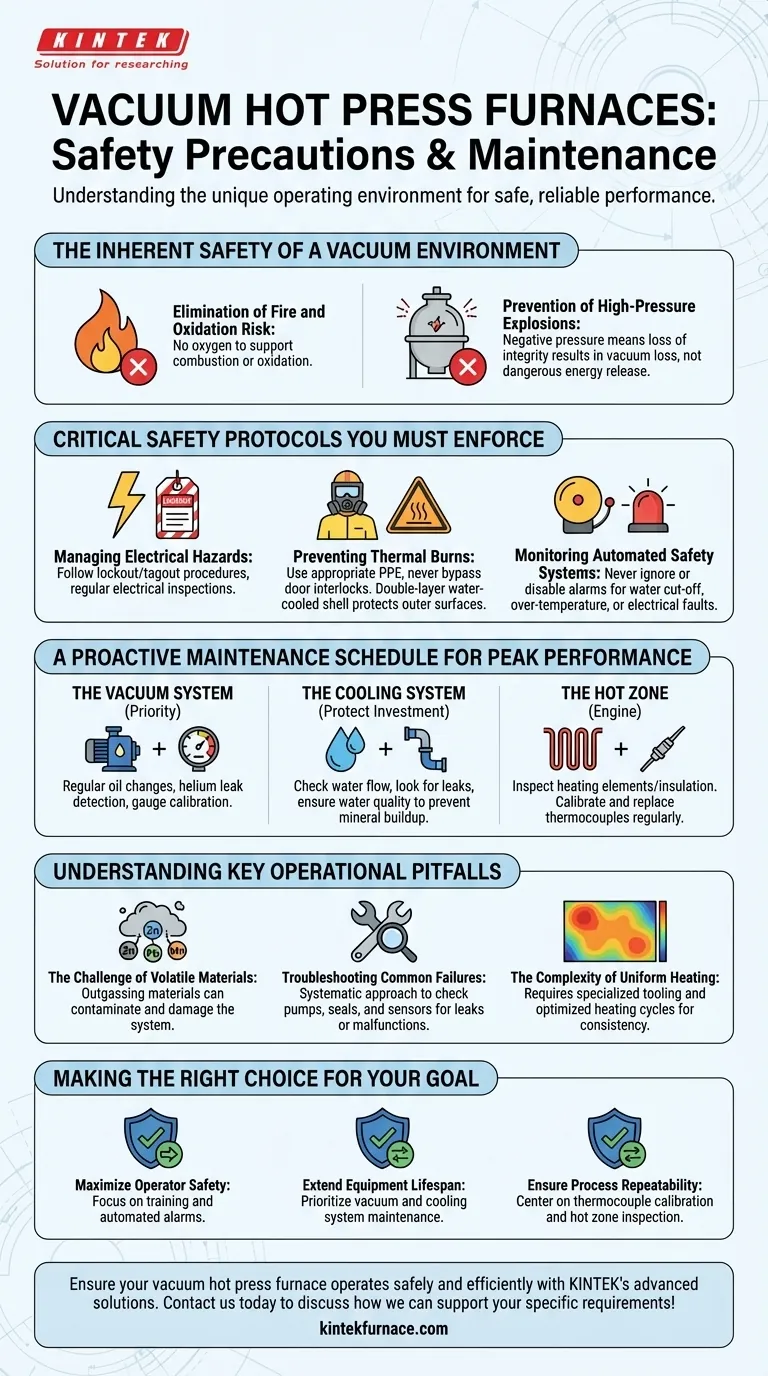

At its core, a vacuum hot press furnace's safety relies on understanding its unique operating environment. Unlike conventional furnaces, the primary risks are not fire or explosion due to the vacuum, but rather electrical hazards, high temperatures, and the specific demands of maintaining the vacuum system itself. A disciplined maintenance schedule focused on the vacuum pumps, cooling circuits, and hot zone components is non-negotiable for safe and reliable operation.

While the vacuum environment inherently eliminates the risk of fire and high-pressure explosions, furnace reliability and operator safety depend entirely on proactive maintenance of the vacuum, cooling, and control systems.

The Inherent Safety of a Vacuum Environment

A key advantage of a vacuum furnace is how its fundamental design mitigates some of the most common industrial heating risks. The physics of operating in a vacuum creates a more controlled and safer environment.

Elimination of Fire and Oxidation Risk

Because a vacuum is, by definition, a space with extremely low oxygen content, it cannot support combustion. This lack of oxygen prevents workpieces or internal furnace components from oxidizing or catching fire at high temperatures, a significant advantage over atmospheric furnaces.

Prevention of High-Pressure Explosions

Vacuum furnaces operate at negative pressure. Unlike pressure vessels or boilers that can fail catastrophically from over-pressurization, a vacuum system poses no such explosion risk. A loss of integrity results in a loss of vacuum, not a dangerous release of energy.

Critical Safety Protocols You Must Enforce

Despite its inherent advantages, a vacuum furnace is a complex piece of industrial equipment with significant thermal and electrical energy. Strict protocols are essential.

Managing Electrical Hazards

These furnaces use high-power systems to generate heat. All personnel must follow standard lockout/tagout procedures during maintenance to prevent electrocution. Regular inspection of wiring and electrical cabinets is mandatory.

Preventing Thermal Burns

The exterior of the furnace is protected by a double-layer water-cooled shell, which keeps the outer surfaces at a safe temperature. However, the interior and the workpiece will be at extreme temperatures. Operators must use appropriate personal protective equipment (PPE) and never bypass door interlocks.

Monitoring Automated Safety Systems

Modern furnaces are equipped with highly automated safety interlocks. These systems provide audible and visual alarms for critical failures like a water cut-off in the cooling system, over-temperature conditions, or electrical over-currents. These alarms must never be ignored or disabled.

A Proactive Maintenance Schedule for Peak Performance

Consistent performance and long equipment life are directly tied to a rigorous preventative maintenance program. Problems are far easier and cheaper to prevent than to fix.

The Vacuum System: Your First Priority

The vacuum pumps, seals, and gauges are the heart of the system. Regular oil changes for pumps, leak-checking of all seals and connections with a helium leak detector, and calibration of vacuum gauges are essential to achieve and hold the required vacuum levels.

The Cooling System: Protecting Your Investment

The water-cooling system protects the entire furnace shell, power feedthroughs, and vacuum chamber from the intense heat. You must regularly check for adequate water flow, look for leaks, and ensure water quality to prevent mineral buildup that can clog cooling channels.

The Hot Zone: The Engine of the Furnace

The hot zone contains the heating elements, insulation, and thermocouples. Heating elements made of graphite or refractory metals degrade over time and require periodic inspection and replacement. Graphite felt or board insulation can become brittle and should also be inspected.

Thermocouple Calibration and Integrity

Thermocouples are the sensors that measure and control temperature. Their accuracy is vital for process repeatability. They must be calibrated regularly and replaced if they show signs of failure or drift, as an inaccurate reading can ruin a workpiece or damage the furnace.

Understanding Key Operational Pitfalls

Operating a vacuum furnace effectively requires understanding its limitations and the common issues that can arise during processing.

The Challenge of Volatile Materials

Certain materials have a high saturated vapor pressure and will evaporate or "outgas" under vacuum at high temperatures. Materials like zinc, lead, manganese, copper, and aluminum can contaminate the furnace interior, coat insulation, and damage vacuum pumps. Processing these materials requires extreme care or may be entirely unsuitable for a vacuum environment.

Troubleshooting Common Failures

When problems like an inability to reach the target vacuum level occur, a systematic approach is needed. Troubleshooting involves checking each stage of the pumping system, inspecting for leaks, and ensuring all system sequences are functioning correctly. Failures are often traced to a worn pump, a compromised seal, or thermocouple malfunction.

The Complexity of Uniform Heating

Achieving perfectly uniform temperature across large or complex-shaped workpieces can be challenging. It often requires specialized tooling, careful part placement, and optimized heating cycles to ensure all areas of the part reach the desired temperature without overheating others.

Making the Right Choice for Your Goal

Your maintenance and safety focus should align with your primary operational objective.

- If your primary focus is maximizing operator safety: Enforce rigorous training on electrical hazards and thermal PPE, and treat every automated alarm as a critical stop-work event.

- If your primary focus is extending equipment lifespan: Prioritize a strict, preventative maintenance schedule for the vacuum pumps and water-cooling system, as these protect the entire investment.

- If your primary focus is ensuring process repeatability: Center your efforts on regular thermocouple calibration, hot zone inspection, and diligent vacuum leak-checking to guarantee a consistent processing environment.

Ultimately, viewing the furnace not just as a tool but as an integrated system to be managed proactively is the key to safe, reliable, and high-quality production.

Summary Table:

| Aspect | Key Focus |

|---|---|

| Safety | Electrical hazards, thermal burns, automated alarms |

| Maintenance | Vacuum system, cooling circuits, hot zone components |

| Operational Pitfalls | Volatile materials, uniform heating challenges |

| Goals | Operator safety, equipment lifespan, process repeatability |

Ensure your vacuum hot press furnace operates safely and efficiently with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, enhancing reliability and performance. Contact us today to discuss how we can support your specific requirements!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification