At a minimum, every modern porcelain furnace must be equipped with dedicated hardware safeguards. These include high-accuracy temperature and pressure sensors to monitor the firing environment and an accessible emergency shut-off switch. These features are the non-negotiable foundation for protecting the operator from harm, the patient's restoration from catastrophic failure, and the equipment from damage.

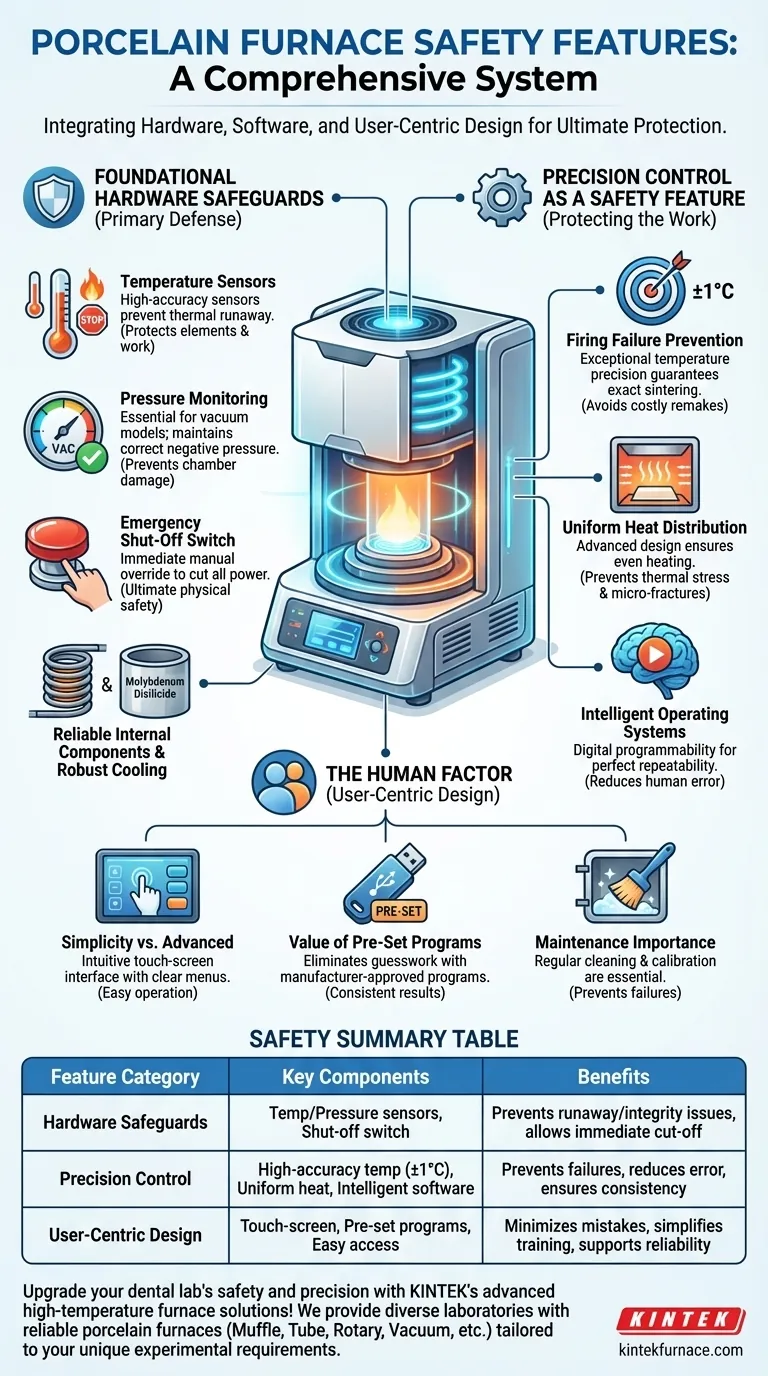

True furnace safety is not just a single feature, but a comprehensive system. It combines physical hardware failsafes with intelligent software control and a user-centric design to prevent both immediate physical danger and costly operational errors.

Foundational Hardware Safeguards

The most critical safety features are the physical components designed to prevent the worst-case scenarios. These are your primary line of defense.

The Role of Temperature Sensors

A furnace's core function is generating extreme heat, making temperature control the primary safety concern. High-quality sensors, often paired with a reliable digital controller, prevent thermal runaway.

These systems ensure the furnace does not exceed its design temperature or the specific parameters of the ceramic, which could destroy the restoration and damage the heating elements.

Pressure Monitoring in Vacuum Models

For furnaces that use a vacuum to reduce porosity in porcelain, pressure sensors are essential. They ensure the correct negative pressure is achieved and maintained.

A faulty vacuum system can compromise the integrity of the restoration, and monitoring prevents potential damage to the chamber or pump from operating outside of safe parameters.

The Emergency Shut-Off Switch

This is the ultimate manual override. In the event of a software glitch, unexpected noise, or any perceived malfunction, the emergency stop provides an immediate way to cut all power to the system.

Its placement should be obvious and easily accessible, allowing any operator to react instantly in a crisis without navigating menus.

Reliable Internal Components

Safety is also a function of build quality. Key components like the heating elements, often made of durable molybdenum disilicide, and the heating chamber material must be able to withstand thousands of high-temperature cycles without degradation.

A robust cooling system is equally important for safely bringing the chamber back to room temperature and ensuring the long-term reliability of the furnace.

Precision Control as a Safety Feature

Beyond preventing physical accidents, a key aspect of "safety" in a dental lab is protecting the work itself. Costly and time-consuming failures during the firing cycle are a significant risk, and modern furnace controls are designed to prevent them.

Preventing Firing Failures

Exceptional temperature precision, often within +/- 1 degree Celsius, is a powerful safety feature. It guarantees that the porcelain undergoes the exact sintering process it was designed for.

This accuracy prevents issues like discoloration, shrinkage, or cracking, effectively safeguarding the restoration's quality and saving the lab from expensive remakes.

The Importance of Uniform Heat Distribution

An advanced chamber design ensures that heat is distributed evenly around the entire restoration. This uniformity is critical for preventing thermal stress and micro-fractures.

Inconsistent heating is a common cause of failed restorations, especially with complex, multi-unit bridges. A well-designed furnace mitigates this risk.

Intelligent Operating Systems

Modern furnaces feature intelligent software with digital programmability. This allows technicians to execute complex, multi-stage firing cycles with perfect repeatability.

By automating the process, the system reduces the likelihood of human error, which is a major source of failed work. The ability to save and recall programs for specific materials provides consistency and operational safety.

Understanding the Trade-offs: The Human Factor

A furnace is only as safe as its operator. The design of the user interface plays a critical role in preventing mistakes.

Simplicity vs. Advanced Functionality

A furnace must be easy to operate, even for technicians with minimal training. An intuitive, touch-screen interface with clear menus is now the standard.

While advanced programmability is crucial, it should not come at the expense of a straightforward control panel. A confusing system increases the risk of an operator inputting incorrect parameters.

The Value of Pre-Set Programs

Many furnaces come with pre-set firing programs for common ceramic systems. This feature is a significant safety benefit, as it removes guesswork and ensures consistent, manufacturer-approved results.

The ability to add custom programs via USB or internal storage combines this safety with the flexibility needed for custom work.

The Hidden Risk of Poor Maintenance

No set of safety features can compensate for a lack of proper maintenance. Regular cleaning of the firing chamber and periodic calibration of the temperature controller are essential for safe and accurate operation.

Neglecting maintenance can lead to inaccurate firing temperatures and component failure, undermining all built-in safety mechanisms.

Making the Right Choice for Your Goal

When evaluating a porcelain furnace, your choice should align directly with your lab's primary needs and workflow.

- If your primary focus is high-volume, standardized production: Prioritize a furnace with extensive pre-set program storage and a simple, intuitive user interface to minimize operator error and maximize throughput.

- If your primary focus is custom, complex restorations: Demand superior temperature accuracy (+/- 1°C), advanced programmability, and a chamber designed for exceptionally uniform heat distribution.

- If your primary focus is operator safety and ease of training: Insist on clear hardware failsafes like an emergency stop, reliable internal components, and a user-friendly touchscreen interface that simplifies operation.

A truly safe furnace is one that reliably protects your staff, your work, and your investment through intelligent and robust design.

Summary Table:

| Feature Category | Key Components | Benefits |

|---|---|---|

| Hardware Safeguards | Temperature sensors, pressure sensors, emergency shut-off switch | Prevents thermal runaway, ensures vacuum integrity, allows immediate power cut in emergencies |

| Precision Control | High-accuracy temperature control (±1°C), uniform heat distribution, intelligent software | Prevents firing failures, reduces human error, ensures consistent results |

| User-Centric Design | Touch-screen interface, pre-set programs, easy maintenance access | Minimizes operator mistakes, simplifies training, supports reliable operation |

Upgrade your dental lab's safety and precision with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable porcelain furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, protecting your staff, work, and investment. Contact us today to learn how our tailored solutions can enhance your lab's efficiency and safety!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations