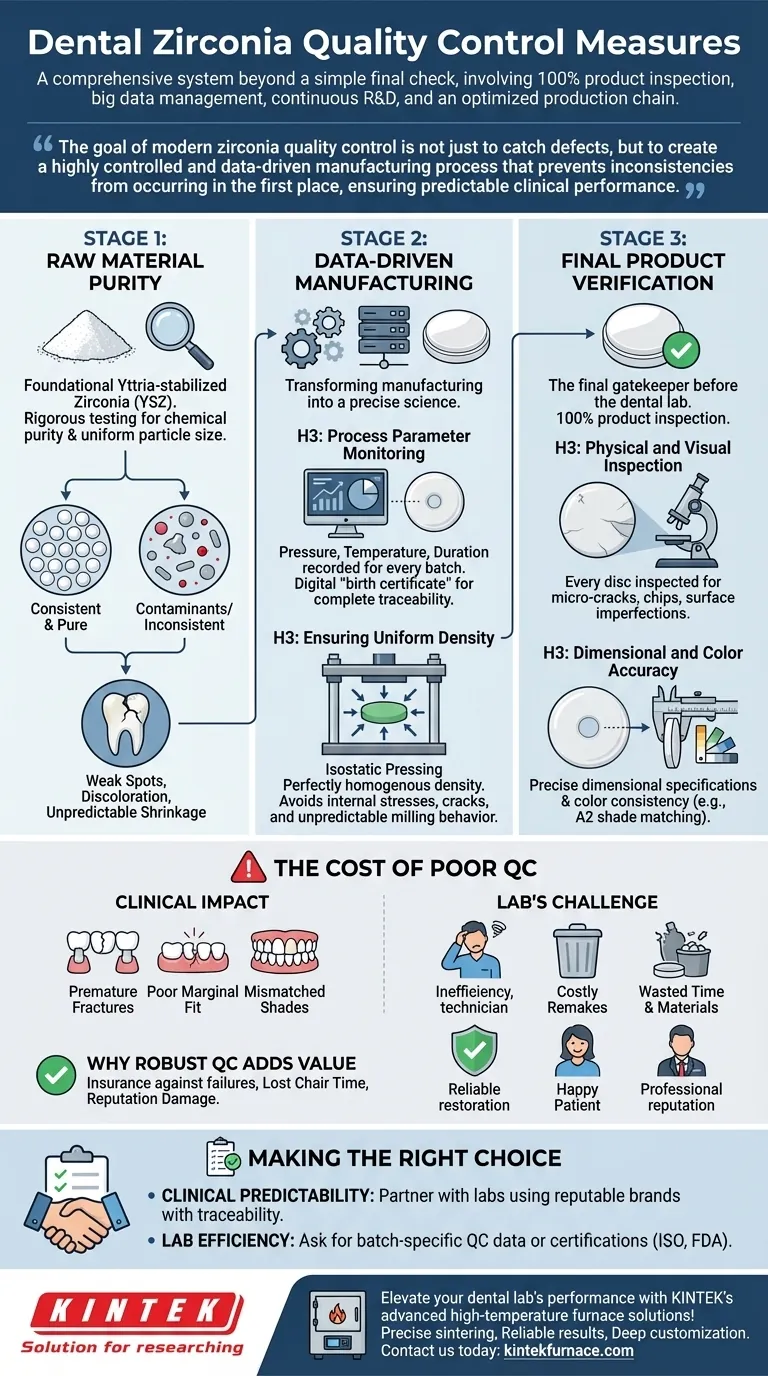

At its core, quality control for dental zirconia is a comprehensive system that extends far beyond a simple final check. It involves 100% product inspection, the use of big data management to track manufacturing consistency, continuous research and development to refine materials, and an optimized production chain to ensure reliability from raw powder to the final milled restoration.

The goal of modern zirconia quality control is not just to catch defects, but to create a highly controlled and data-driven manufacturing process that prevents inconsistencies from occurring in the first place, ensuring predictable clinical performance.

The Pillars of Zirconia Quality Control

True quality control is a multi-stage process. Each stage builds upon the last to create a product that is safe, reliable, and aesthetically pleasing. A failure at any point compromises the final result.

Stage 1: Raw Material Purity

The process begins with the foundational zirconia powder, typically Yttria-stabilized Zirconia (YSZ). The quality of this initial material dictates the potential of the final product.

Control at this stage involves rigorous testing for chemical purity and ensuring a uniform, pre-determined particle size. Contaminants or inconsistent particle sizes can lead to weak spots, discoloration, or unpredictable shrinkage during sintering.

Stage 2: Data-Driven Manufacturing

This is where terms like "comprehensive QC systems" and "big data management" come into play. It’s about transforming the art of manufacturing into a precise science.

H3: Process Parameter Monitoring

Every step, from the pressing of the powder into a disc to the pre-sintering phase, is monitored. Key parameters like pressure, temperature, and duration are recorded for every single batch.

This data creates a digital "birth certificate" for each disc, allowing for complete traceability.

H3: Ensuring Uniform Density

The goal is to produce a disc with perfectly homogenous density. Any variations can cause internal stresses, leading to cracks or unpredictable milling behavior. Isostatic pressing, where pressure is applied evenly from all directions, is a key technique used to achieve this uniformity.

Stage 3: Final Product Verification

This is the "100% product inspection" stage, acting as the final gatekeeper before the product reaches a dental lab.

H3: Physical and Visual Inspection

Every single disc is inspected for physical defects. This includes looking for micro-cracks, chips, or surface imperfections that could compromise the integrity of a final restoration.

H3: Dimensional and Color Accuracy

Discs are measured to ensure they meet precise dimensional specifications. They are also checked for color consistency, ensuring that a disc labeled "A2" perfectly matches the intended shade, which is critical for aesthetic outcomes.

Understanding the Trade-offs: The Cost of Poor QC

Choosing a zirconia product is not just about the initial price. The hidden costs of inconsistent quality can be significant for both dental labs and clinicians.

The Clinical Impact of Inconsistency

Low-quality zirconia, resulting from poor QC, can lead directly to clinical failures. This may manifest as premature fractures of crowns or bridges, poor marginal fit, or restorations that do not match the desired shade.

The Lab's Challenge

For a dental lab, inconsistent zirconia is a major source of inefficiency. A disc that mills poorly, has unpredictable shrinkage rates, or is incorrectly shaded requires costly remakes, wasting both technician time and materials.

Why Robust QC Adds Value

A rigorous quality control system is a significant investment for a manufacturer. This cost is reflected in the product's price, but it serves as an insurance policy against the much greater costs of failed restorations, lost chair time, and damage to a professional's reputation.

Making the Right Choice for Your Goal

Understanding the principles of quality control empowers you to ask the right questions and select materials that support excellent clinical outcomes.

- If your primary focus is clinical predictability: Partner with labs that use reputable zirconia brands and can speak to the traceability and consistency of their materials.

- If your primary focus is lab efficiency: Ask your suppliers for batch-specific QC data or certifications (like ISO or FDA clearance) to ensure the material you buy today will perform exactly like the material you bought last month.

Ultimately, a deep understanding of quality control transforms your material selection from a simple purchase into a strategic clinical decision.

Summary Table:

| Stage | Key Quality Control Measures | Purpose |

|---|---|---|

| Raw Material Purity | Chemical purity testing, uniform particle size | Prevent weak spots, discoloration, and unpredictable shrinkage |

| Data-Driven Manufacturing | Process parameter monitoring, uniform density via isostatic pressing | Ensure traceability, prevent cracks, and maintain consistency |

| Final Product Verification | Physical/visual inspection, dimensional and color accuracy checks | Detect defects, ensure fit, and match aesthetic shades |

Elevate your dental lab's performance with KINTEK's advanced high-temperature furnace solutions! Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by exceptional R&D and in-house manufacturing, ensure precise sintering and reliable results for dental zirconia. With strong deep customization capabilities, we tailor solutions to your unique needs, enhancing efficiency and clinical predictability. Contact us today to discuss how we can support your quality control goals!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations