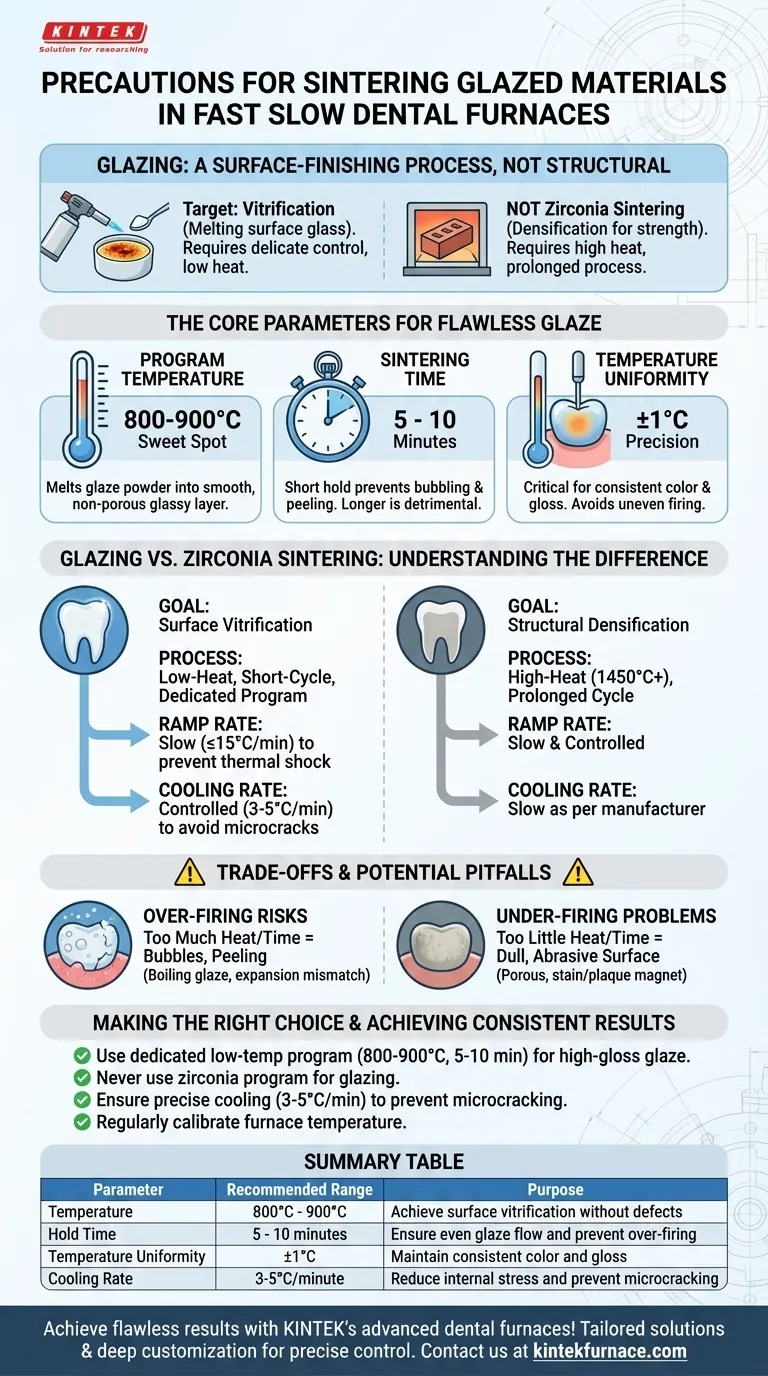

To properly sinter glazed materials, you must use a specific low-temperature program, typically between 800°C and 900°C. The hold time at this peak temperature should be brief, around 5 to 10 minutes, to prevent defects like bubbling or peeling. Maintaining precise temperature uniformity (±1°C) across the restoration is critical to ensure even gloss and consistent color.

The core principle to remember is that glazing is a surface-finishing process, not a structural one. Unlike sintering zirconia for strength, glazing requires just enough heat to melt the glass particles into a smooth, non-porous layer. Success hinges on delicate control, not brute force.

The Core Parameters for Glaze Sintering

Achieving a perfect glaze finish requires dialing in three key parameters. Your furnace's preset programs for glazing are designed around these principles, but understanding them allows for better troubleshooting and customization.

Program Temperature: The 800-900°C Sweet Spot

The goal of a glaze cycle is vitrification—melting the surface glaze powder into a solid, glassy layer.

This process happens at a much lower temperature than the sintering required for a zirconia core. A range of 800°C to 900°C is typically sufficient to achieve a smooth, high-gloss surface.

Sintering Time: A Short Hold for a Perfect Sheen

The hold time at peak temperature should be short, generally between 5 and 10 minutes.

This is just long enough for the glaze to flow evenly across the surface. Extending this time offers no benefit and significantly increases the risk of defects.

Temperature Uniformity: The Key to Consistent Color and Gloss

Modern dental furnaces offer exceptional temperature accuracy, often within ±1°C. This precision is not a luxury; it's a necessity.

Even minor temperature variations across the restoration can cause one area to be perfectly glazed while another is under-fired (dull) or over-fired (bubbly). Uniformity ensures a consistent, professional result.

Why Glazing Differs from Zirconia Sintering

A "Fast Slow" furnace is designed for multiple materials, and it's vital to understand that the process for glazing is fundamentally different from that for sintering a zirconia substructure.

The Goal: Surface Vitrification vs. Structural Densification

Think of glazing as melting a sugar crust on a crème brûlée—it's a quick, low-heat process focused entirely on the surface.

Sintering zirconia, conversely, is like firing a brick in a kiln. It's a high-heat, prolonged process (e.g., 1450-1600°C) designed to shrink and densify the material, giving it its final strength.

The Process: Different Modes for Different Materials

The "Slow" mode of your furnace, which refers to the heating and cooling rate, is often ideal for all-ceramic materials, including glazing.

A slower ramp rate (e.g., ≤15°C/minute) prevents thermal shock and cracking. However, the overall glaze cycle is much faster than a zirconia cycle because the peak temperature is lower and the hold time is minimal. Always use a separate, dedicated program for glazing.

Understanding the Trade-offs and Potential Pitfalls

Deviating from the ideal parameters can quickly lead to failed restorations. Understanding these common failure modes is key to avoiding them.

The Risk of Over-firing: Bubbles and Peeling

Too much heat or too much time will cause the glaze to "boil" as gases escape, creating bubbles. In severe cases, the different expansion properties between the glaze and the substructure can cause the glaze to peel or flake off.

The Problem with Under-firing: A Dull, Abrasive Surface

If the temperature is too low or the hold time is too short, the glaze particles will not fully melt and fuse. This results in a porous, abrasive, and dull surface that will easily attract stains and plaque.

The Impact of Cooling Rate

Just as a slow heating rate is important, a controlled cooling rate is critical. Rapid cooling introduces internal stress into the glassy glaze layer, which can cause microcracks and compromise the restoration's longevity. A slow cooling rate of 3-5°C/minute is often recommended for ceramic materials.

Making the Right Choice for Your Goal

Use these principles to refine your workflow and ensure predictable, high-quality outcomes for every case.

- If your primary focus is a high-gloss, natural-looking glaze: Prioritize a low-temperature program (800-900°C) with a short hold time (5-10 minutes) and a controlled, slow cooling rate.

- If you are sintering a zirconia substructure: Use a completely separate, high-temperature program (1450°C+) with slow heating and cooling ramps as defined by the zirconia manufacturer.

- If you want to ensure consistent results every time: Implement a routine of regular furnace temperature calibration and use dedicated, clearly labeled programs for each material you use.

Mastering your furnace's settings for different materials is the key to transforming good restorations into exceptional ones.

Summary Table:

| Parameter | Recommended Range | Purpose |

|---|---|---|

| Temperature | 800°C - 900°C | Achieve surface vitrification without defects |

| Hold Time | 5 - 10 minutes | Ensure even glaze flow and prevent over-firing |

| Temperature Uniformity | ±1°C | Maintain consistent color and gloss across restoration |

| Cooling Rate | 3-5°C/minute | Reduce internal stress and prevent microcracking |

Achieve flawless glazing results with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide dental laboratories with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise control for your unique sintering needs—contact us today via our contact form to enhance your lab's efficiency and quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow