At its core, a vacuum sintering furnace is designed for materials that cannot tolerate the presence of air or other gases during high-temperature processing. These furnaces are primarily used for sintering a range of advanced materials, including reactive metals like titanium, refractory metals, hard alloys, advanced ceramics, and high-performance magnetic materials.

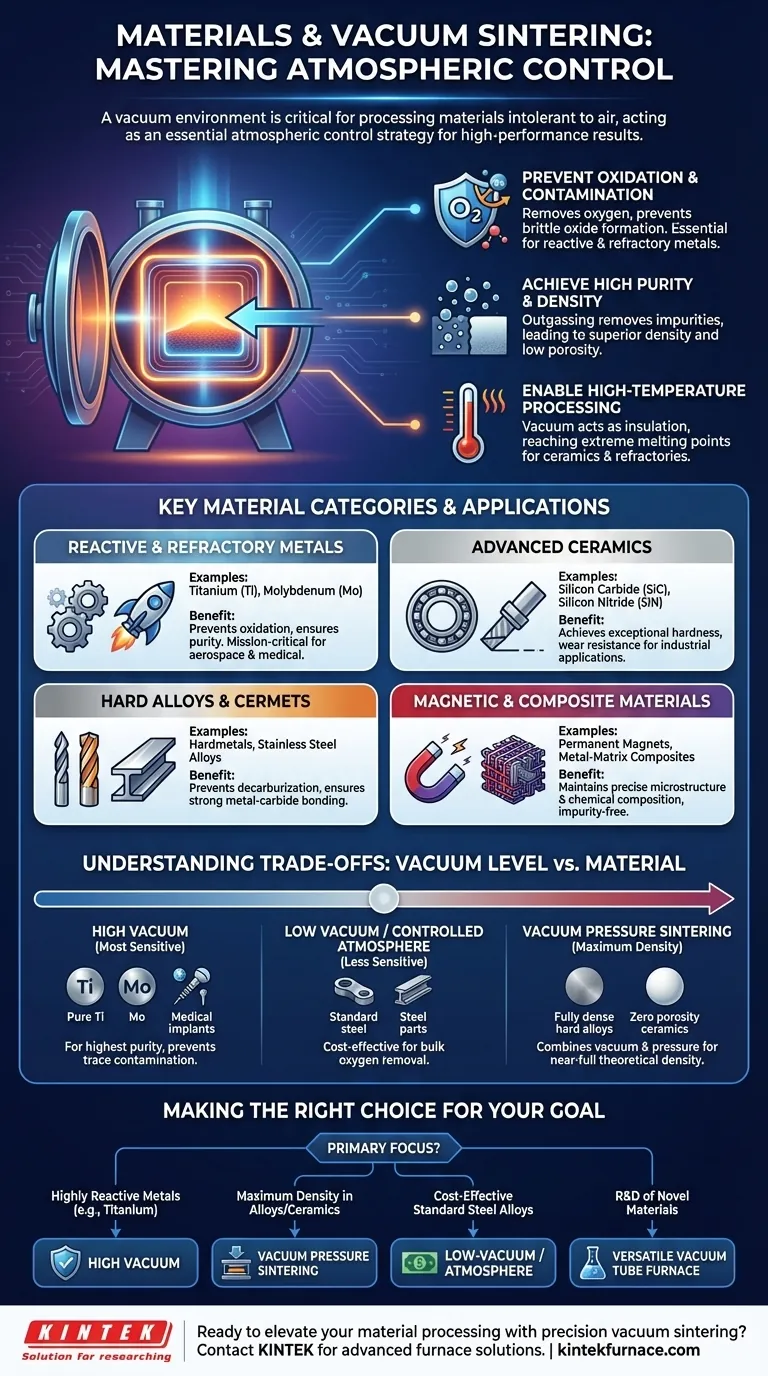

The crucial insight is that vacuum sintering is not just a heating method; it is an atmospheric control strategy. The vacuum environment is essential for preventing oxidation, removing contaminants, and achieving the high purity and density required by mission-critical components.

Why a Vacuum Environment is Critical

The decision to use a vacuum furnace is driven by the material's chemical properties and the desired final characteristics. The vacuum provides distinct advantages over conventional atmosphere-based sintering.

Preventing Oxidation and Contamination

Many advanced materials are highly reactive, especially at the elevated temperatures required for sintering.

A vacuum environment removes oxygen and other atmospheric gases that would otherwise react with the material, forming brittle oxides or other undesirable compounds. This is non-negotiable for reactive metals like titanium and refractory metals like molybdenum.

Achieving High Purity and Density

The vacuum actively pulls trapped gases and volatile impurities out from the powdered material during the heating cycle.

This process, known as outgassing, results in a final product with significantly higher purity and lower porosity. The removal of internal gases allows the material particles to bond more effectively, leading to superior density.

Enabling High-Temperature Processing

Vacuum is an excellent thermal insulator, which helps in achieving and maintaining the extremely high temperatures needed for sintering certain materials.

This is particularly important for advanced ceramics and refractory metals, which have melting points far beyond the capability of many standard furnaces.

Key Material Categories and Their Applications

The unique benefits of a vacuum environment make it the ideal choice for several classes of high-performance materials.

Reactive and Refractory Metals

These materials, including titanium (Ti) and molybdenum (Mo), are the primary candidates for vacuum sintering. Their strong affinity for oxygen makes processing in any other atmosphere impractical, as it would lead to component failure.

Advanced Ceramics

Materials like silicon carbide (SiC) and silicon nitride (SiN) are sintered in high-temperature vacuum furnaces to produce exceptionally hard and wear-resistant components. These are often used in high-performance applications such as industrial bearings, seals, and cutting tools.

Hard Alloys and Cermets

This category includes hardmetals (cemented carbides) and high-strength stainless steel alloys. Vacuum sintering prevents the loss of carbon (decarburization) in steels and ensures a clean, strong bond between the metal binder and carbide particles in hardmetals.

Magnetic and Composite Materials

High-performance permanent magnets and specialized metal-matrix composites rely on vacuum processing to achieve their precise chemical composition and microstructure. The clean environment ensures that the final magnetic or structural properties are not compromised by impurities.

Understanding the Trade-offs: Vacuum Level vs. Material

Not all vacuum furnaces are the same. The choice of furnace often comes down to balancing performance requirements with cost.

High Vacuum for Sensitive Materials

A high vacuum environment is required for the most sensitive and high-purity materials. If you are working with titanium, pure molybdenum, or materials for medical or aerospace applications, a high vacuum furnace is essential to prevent any trace contamination.

Low Vacuum for Less Sensitive Materials

For less reactive materials, such as many steel alloys, a low vacuum or controlled atmosphere furnace can be a more cost-effective solution. This approach still removes the bulk of the oxygen, providing significant benefits over open-air sintering without the cost of a high-vacuum system.

Pressure Sintering for Maximum Density

Some advanced furnaces combine vacuum with high pressure (Vacuum Pressure Sintering). This process is used for materials like hard alloys and ceramics where achieving near-full theoretical density is the primary goal, virtually eliminating all porosity.

Making the Right Choice for Your Goal

The optimal sintering process depends entirely on your material and the performance you need to achieve.

- If your primary focus is processing highly reactive metals (e.g., titanium): High vacuum is non-negotiable to prevent catastrophic oxidation.

- If your primary focus is achieving maximum density in hard alloys or ceramics: A vacuum pressure sintering process will deliver the best results by eliminating residual porosity.

- If your primary focus is cost-effective sintering of standard steel alloys: A low-vacuum or controlled atmosphere furnace offers a good balance of quality and economy.

- If your primary focus is research and development of novel materials: A versatile vacuum tube furnace provides the precise control needed for experimental work.

Ultimately, selecting the correct atmospheric conditions is as critical as selecting the material itself for achieving peak performance.

Summary Table:

| Material Category | Key Examples | Primary Benefits |

|---|---|---|

| Reactive & Refractory Metals | Titanium, Molybdenum | Prevents oxidation, ensures purity |

| Advanced Ceramics | Silicon Carbide, Silicon Nitride | Achieves high density, wear resistance |

| Hard Alloys & Cermets | Hardmetals, Stainless Steel | Prevents decarburization, strong bonding |

| Magnetic & Composite Materials | Permanent Magnets, Metal-Matrix Composites | Maintains precise microstructure, impurity-free |

Ready to elevate your material processing with precision vacuum sintering? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories working with reactive metals, ceramics, and alloys. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance purity, density, and performance in your applications!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes