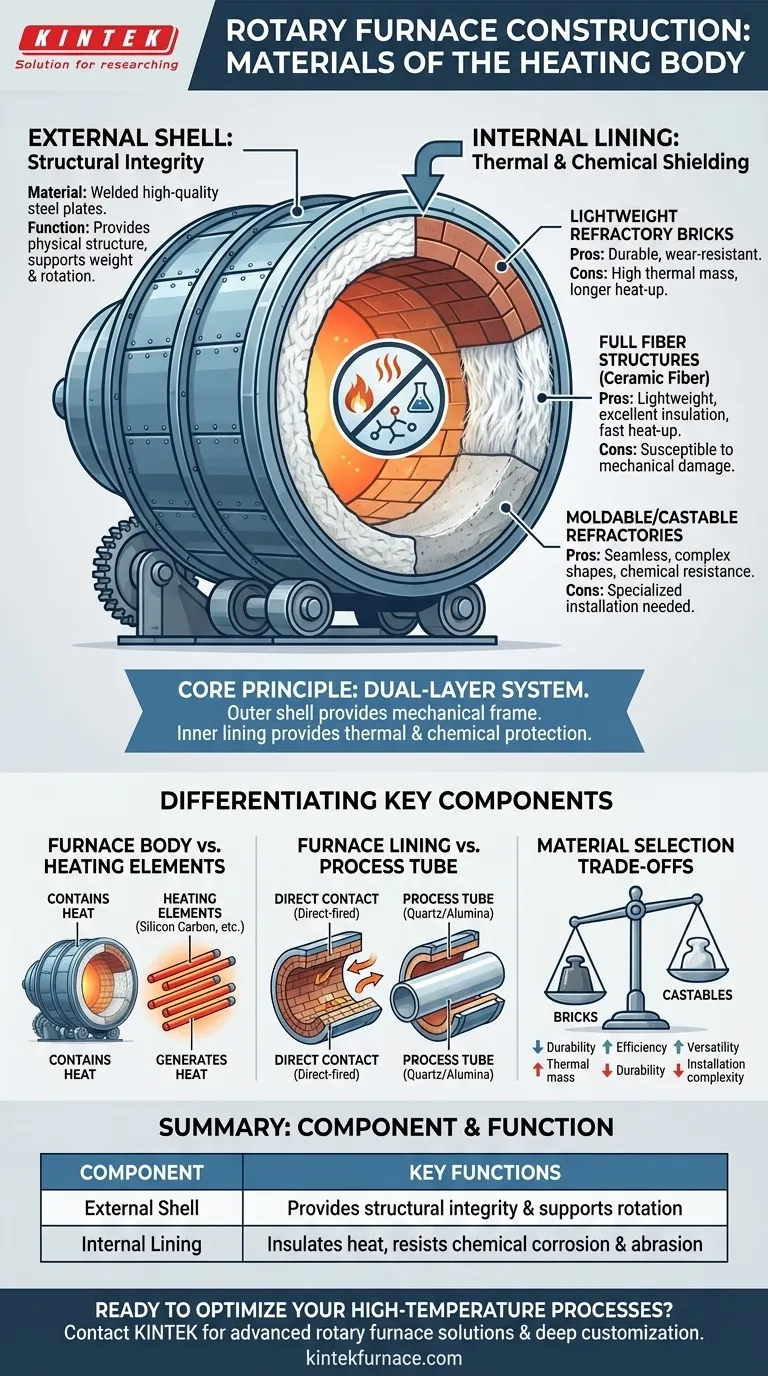

At its core, a rotary furnace's heating body is a dual-layer system. The external structure is built for mechanical strength using welded steel plate, while the critical internal furnace lining is constructed from specialized refractory materials designed to contain extreme heat and resist chemical corrosion. These inner materials typically include lightweight refractory bricks or advanced full fiber structures.

The essential principle is a division of labor: an outer steel shell provides the structural frame and mechanical integrity for rotation, while an inner refractory lining provides the thermal insulation and chemical protection required for high-temperature processing.

The Anatomy of a Rotary Furnace Body

To understand the furnace's performance and durability, you must look at its construction as two distinct but complementary components: the external shell and the internal lining.

The External Shell: Structural Integrity

The main body, or shell, of a rotary furnace is a large cylindrical barrel. This component's primary role is to provide the physical structure of the furnace.

It is typically fabricated by welding together high-quality steel plates. This construction ensures the furnace has the necessary rigidity to support its own weight, the weight of the refractory lining, and the material being processed, all while enduring the mechanical stresses of continuous rotation.

The Internal Lining: Thermal and Chemical Shielding

The furnace lining is the true heart of the thermal operation. It sits inside the steel shell and serves two critical functions: insulating the shell from extreme temperatures and protecting it from chemical attack or abrasion by the process material.

The choice of lining material is dictated by the furnace's specific application, but the most common options include:

- Lightweight Refractory Insulation Bricks: These are a traditional and robust choice, offering good durability and resistance to wear.

- Full Fiber Structures: Modern furnaces often use ceramic fiber insulation. This material is extremely lightweight and offers superior thermal insulation, leading to better energy efficiency and faster heat-up times.

- Moldable or Castable Refractories: These are cement-like materials that are applied to form a solid, seamless lining. They are excellent for creating complex shapes and providing high resistance to chemical infiltration.

Differentiating Key Furnace Components

It is easy to confuse the furnace body with other internal parts. A clear distinction is essential for understanding the system.

Furnace Body vs. Heating Elements

The furnace body and its lining are designed to contain the heat. The heating elements are what generate the heat.

These elements are made from materials with high electrical resistance and temperature stability, such as silicon carbon rods, silicon molybdenum rods, or graphite. They are installed within the furnace but are separate components from the lining itself.

Furnace Lining vs. Process Tube

In other types of furnaces, like a tube furnace, a separate process tube made of quartz or alumina holds the material being heated.

In a direct-fired rotary furnace, however, the internal surface of the furnace lining is often the component in direct contact with the process material. This makes the choice of lining material even more critical, as it must be chemically compatible with the substance being heated.

Understanding the Trade-offs in Material Selection

The choice between refractory bricks, fiber, or castables is not arbitrary; it is a calculated decision based on balancing performance, cost, and operational demands.

Refractory Bricks: Durability vs. Thermal Mass

Bricks are exceptionally durable and resistant to mechanical abrasion, making them ideal for heavy-duty applications. However, they are heavy and possess high thermal mass, meaning the furnace takes longer to heat up and cool down, potentially impacting energy efficiency.

Full Fiber Structures: Efficiency vs. Susceptibility

A full fiber lining provides outstanding insulation and low thermal mass, enabling rapid heating cycles and reducing energy consumption. The trade-off is that these materials can be more susceptible to mechanical damage and may not be suitable for processes involving highly abrasive or corrosive materials.

Moldable/Castable Refractories: Versatility vs. Installation

Castable materials offer the significant advantage of forming a seamless, joint-free lining, which is ideal for preventing leakage and conforming to complex furnace geometries. However, their installation requires specialized expertise, precise mixing, and controlled curing procedures to ensure long-term integrity.

Making the Right Choice for Your Application

Selecting the appropriate furnace construction depends entirely on your process requirements. The materials used in the lining are a direct reflection of the furnace's intended purpose.

- If your primary focus is processing abrasive, high-volume materials: A lining of dense, durable refractory brick is the most reliable choice.

- If your primary focus is energy efficiency and rapid thermal cycling: A lightweight, full fiber structure will deliver superior performance.

- If your primary focus is containing highly corrosive materials or unique process shapes: A specialized castable or moldable refractory provides the best solution for a seamless, chemically resistant lining.

Understanding this dual-layer construction of a structural shell and a functional lining is the key to selecting, operating, and maintaining a rotary furnace for optimal performance.

Summary Table:

| Component | Material Options | Key Functions |

|---|---|---|

| External Shell | Welded steel plates | Provides structural integrity and supports rotation |

| Internal Lining | Lightweight refractory bricks, full fiber structures, moldable/castable refractories | Insulates heat, resists chemical corrosion and abrasion |

Ready to optimize your high-temperature processes? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced rotary furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental needs. Contact us today to discuss how our tailored furnace designs can enhance your lab's efficiency and durability!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control