At its core, dental zirconia's clinical effectiveness stems from a unique combination of exceptional mechanical strength, advanced aesthetic properties, and excellent biocompatibility. This blend allows it to serve demanding functional roles, such as in posterior bridges, while also meeting the high aesthetic requirements for anterior restorations, a versatility few other materials can match.

The crucial insight is that modern zirconia is not a single material, but a class of materials. Its success comes from the ability to engineer different formulations that balance industry-leading strength with increasingly natural translucency, allowing clinicians to choose the perfect composition for a specific clinical need.

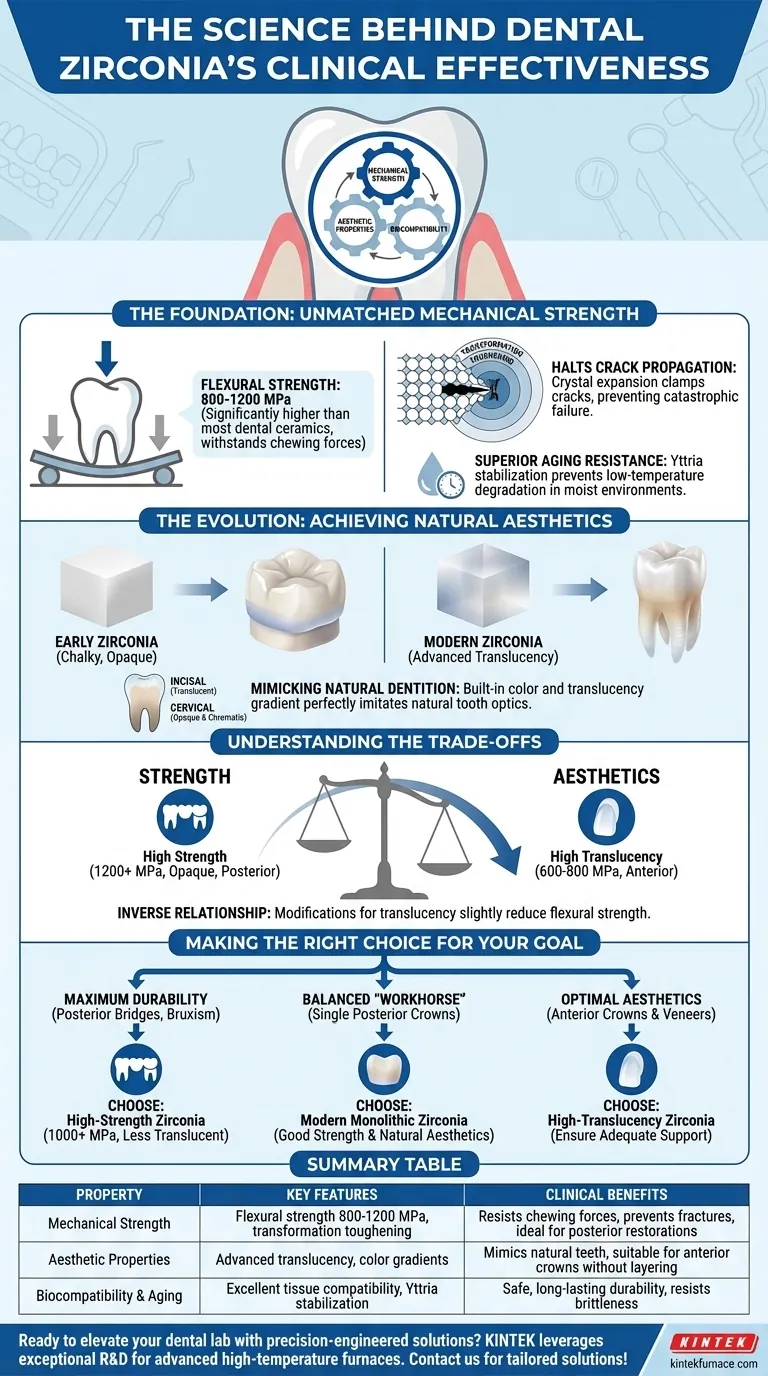

The Foundation: Unmatched Mechanical Strength

The property that first brought zirconia to prominence in dentistry was its incredible durability, which directly translates to clinical longevity.

Flexural Strength and Toughness

Zirconia exhibits a flexural strength typically ranging from 800 to 1200 MPa. This is significantly higher than most other dental ceramics, enabling it to withstand the immense chewing forces exerted in the posterior mouth without fracturing.

This strength is enhanced by a phenomenon called transformation toughening. When a microscopic crack begins to form under stress, the crystal structure of the zirconia around the crack tip expands. This expansion effectively clamps the crack shut, halting its propagation and making the material exceptionally resistant to chipping and catastrophic failure.

Superior Aging Resistance

The "unique molecular structures" mentioned in research refer to the stabilization of zirconia with yttria. This prevents a process known as low-temperature degradation, where the material could become brittle over time when exposed to moisture in the oral environment. Modern dental zirconia demonstrates excellent resistance to this form of aging.

The Evolution: Achieving Natural Aesthetics

While early zirconia was strong, it was also chalky and opaque, limiting its use to frameworks that had to be layered with porcelain. Modern formulations have overcome this limitation.

Advanced Translucency

Contemporary zirconia is engineered for excellent light transmission, allowing it to mimic the translucency of natural enamel. This property is critical for avoiding the flat, artificial look that can occur with less advanced materials, especially in the front of the mouth.

Mimicking Natural Dentition

The most advanced zirconia blocks feature a built-in color and translucency gradient. They are more opaque and chromatic in the cervical (gumline) area and gradually become more translucent toward the incisal (biting) edge.

This multi-layered structure perfectly imitates a natural tooth, which has the same optical gradient. This allows for the creation of monolithic (full-contour) restorations that are both incredibly strong and highly aesthetic without the need for a separate, weaker layer of porcelain.

Understanding the Trade-offs

No material is perfect. The primary trade-off in the world of zirconia is the inverse relationship between strength and translucency.

The Strength vs. Aesthetics Spectrum

As a general rule, the modifications made to a zirconia formulation to increase its translucency slightly reduce its maximum flexural strength.

First-generation zirconia is the strongest (1200+ MPa) but also the most opaque. Newer, "anterior" grade zirconia is much more translucent but may have a lower flexural strength (often in the 600-800 MPa range). This creates a spectrum of options, not a one-size-fits-all solution.

Clinical Implications of Material Choice

This trade-off is not a flaw but a critical factor in case selection. Using a high-translucency material on a long-span posterior bridge may be inappropriate, while using a high-strength, opaque material for a central incisor would be an aesthetic compromise. The expertise lies in matching the material to the specific functional and aesthetic demands of the restoration site.

Making the Right Choice for Your Goal

Selecting the correct class of zirconia is essential for predictable and successful outcomes. Base your decision on the primary requirement of the clinical case.

- If your primary focus is maximum durability (posterior bridges, patients with bruxism): Choose a high-strength (1000+ MPa), less translucent zirconia, often referred to as posterior-grade.

- If your primary focus is optimal aesthetics (anterior crowns and veneers): Choose a high-translucency (anterior-grade) zirconia, ensuring your preparation design provides adequate structural support.

- If you need a balanced "workhorse" material (single posterior crowns): Modern monolithic zirconia with a built-in gradient offers an excellent balance of good strength and natural aesthetics.

By understanding these core properties and their inherent trade-offs, you can leverage zirconia to deliver restorations that are predictable, beautiful, and built to last.

Summary Table:

| Property | Key Features | Clinical Benefits |

|---|---|---|

| Mechanical Strength | Flexural strength 800-1200 MPa, transformation toughening | Resists chewing forces, prevents fractures, ideal for posterior restorations |

| Aesthetic Properties | Advanced translucency, color gradients | Mimics natural teeth, suitable for anterior crowns without layering |

| Biocompatibility | Excellent tissue compatibility | Safe for oral use, reduces risk of adverse reactions |

| Aging Resistance | Yttria stabilization | Long-lasting durability, resists brittleness in moist environments |

Ready to elevate your dental lab with precision-engineered solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, helping you achieve superior results in material testing and production. Contact us today to discuss how our tailored furnace solutions can enhance your workflow and deliver reliable, high-performance outcomes for your dental applications!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency