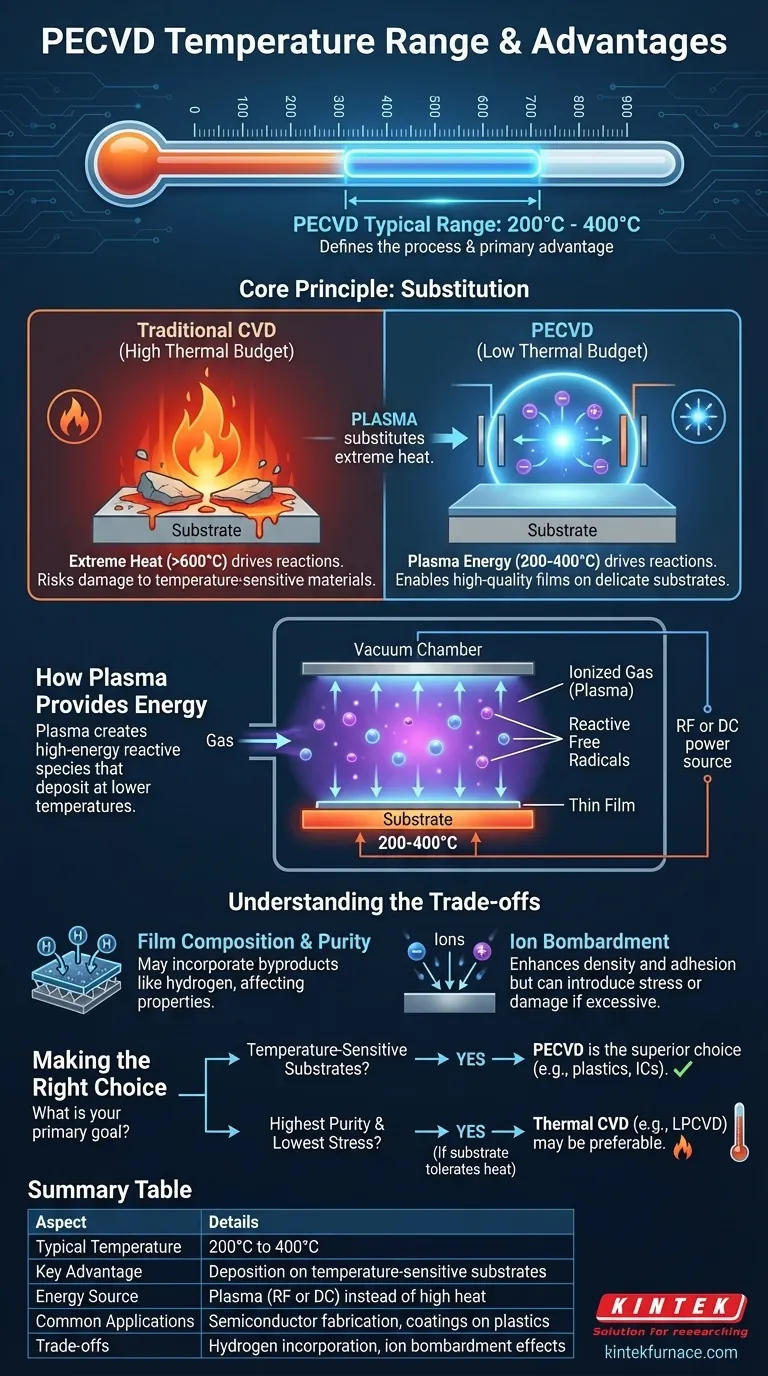

To be direct, the typical operating temperature for Plasma Enhanced Chemical Vapor Deposition (PECVD) is between 200°C and 400°C. This relatively low temperature range is the process's defining characteristic and primary advantage, enabling the deposition of high-quality thin films on substrates that could not survive more traditional, high-temperature methods.

The core principle of PECVD is substitution. Instead of relying solely on extreme heat to drive chemical reactions, it uses the energy from an ionized gas (plasma) to achieve the same goal, fundamentally lowering the thermal budget required for thin film deposition.

Why PECVD Operates at Lower Temperatures

To understand the significance of PECVD's temperature range, we must first look at the limitations of traditional thermal deposition methods.

The Challenge with Traditional CVD

Standard Chemical Vapor Deposition (CVD) relies exclusively on thermal energy to break down precursor gases. Substrates are heated to very high temperatures, often exceeding 600°C or much higher.

This high "thermal budget" provides the activation energy needed for gas molecules to react and form a solid film on the substrate surface. However, such intense heat can damage or destroy many materials, including plastics, certain semiconductors with existing integrated circuits, and other temperature-sensitive components.

How Plasma Provides the Energy

PECVD circumvents the need for extreme heat by introducing an alternative energy source: plasma.

Inside a vacuum chamber, precursor gases are introduced between two electrodes. A radio frequency (RF) or direct current (DC) voltage is applied, which strips electrons from the gas molecules and creates a glowing, ionized gas—the plasma.

This plasma is a high-energy environment. The collisions within the plasma create highly reactive free radicals that can then deposit onto the substrate at much lower temperatures. The substrate is still heated, but only to the 200-400°C range, which is sufficient to promote surface diffusion and ensure a dense, uniform film.

Understanding the Trade-offs

The lower operating temperature of PECVD is a powerful advantage, but it comes with considerations that distinguish it from purely thermal processes.

Film Composition and Purity

Because the deposition occurs at lower temperatures, PECVD films can sometimes incorporate byproducts from the precursor gases, such as hydrogen. For example, silicon nitride (SiNₓ) films deposited via PECVD often contain significant amounts of hydrogen, which can affect their electrical and optical properties.

Higher-temperature processes, like Low-Pressure CVD (LPCVD), often yield films with higher purity and better stoichiometry because the heat more effectively drives off unwanted elements.

The Role of Ion Bombardment

The plasma that enables low-temperature deposition also bombards the substrate surface with energetic ions. This can be beneficial, as it can increase film density and adhesion.

However, excessive ion bombardment can also introduce stress into the film or even cause physical damage to the substrate surface, a critical concern in semiconductor fabrication. Process control involves finding the right balance between plasma power, pressure, and temperature.

Making the Right Choice for Your Goal

Selecting a deposition method requires aligning the process capabilities with your primary objective. PECVD's unique temperature profile makes it ideal for specific applications.

- If your primary focus is depositing films on temperature-sensitive substrates: PECVD is the superior, and often only, viable choice. Its low thermal budget protects underlying materials and integrated circuits.

- If your primary focus is achieving the highest possible film purity and lowest stress: A higher-temperature thermal process like LPCVD may be preferable, but only if your substrate can tolerate the intense heat.

- If your primary focus is balancing deposition rate, film quality, and substrate integrity: You must carefully optimize PECVD parameters. The 200°C to 400°C range provides a window where film quality can be tuned without risking thermal damage.

Ultimately, PECVD's use of plasma energy is a strategic trade-off that unlocks thin film deposition for a vast new range of applications.

Summary Table:

| Aspect | Details |

|---|---|

| Typical Temperature Range | 200°C to 400°C |

| Key Advantage | Enables deposition on temperature-sensitive substrates |

| Energy Source | Plasma (RF or DC) instead of high heat |

| Common Applications | Semiconductor fabrication, coatings on plastics |

| Trade-offs | May include hydrogen incorporation and ion bombardment effects |

Need a PECVD system tailored to your lab's unique needs? KINTEK specializes in advanced high-temperature furnace solutions, including PECVD systems, with deep customization to precisely match your experimental requirements. Our expertise in R&D and in-house manufacturing ensures reliable performance for diverse laboratories. Contact us today to discuss how we can enhance your thin film deposition processes!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition