At its core, a Fast Slow Dental Sintering Furnace is built around a double-shell structure with advanced insulation. This design is the key physical component that enables its primary function: achieving both rapid and conventional heating and cooling cycles. This structural design, combined with precise digital controls, gives the furnace its signature versatility.

The true value of a Fast Slow Sintering Furnace is not just its physical construction, but how that structure works in concert with a high-precision control system. This combination provides the flexibility to optimize the sintering process for different materials and desired turnaround times without compromising the final restoration's integrity.

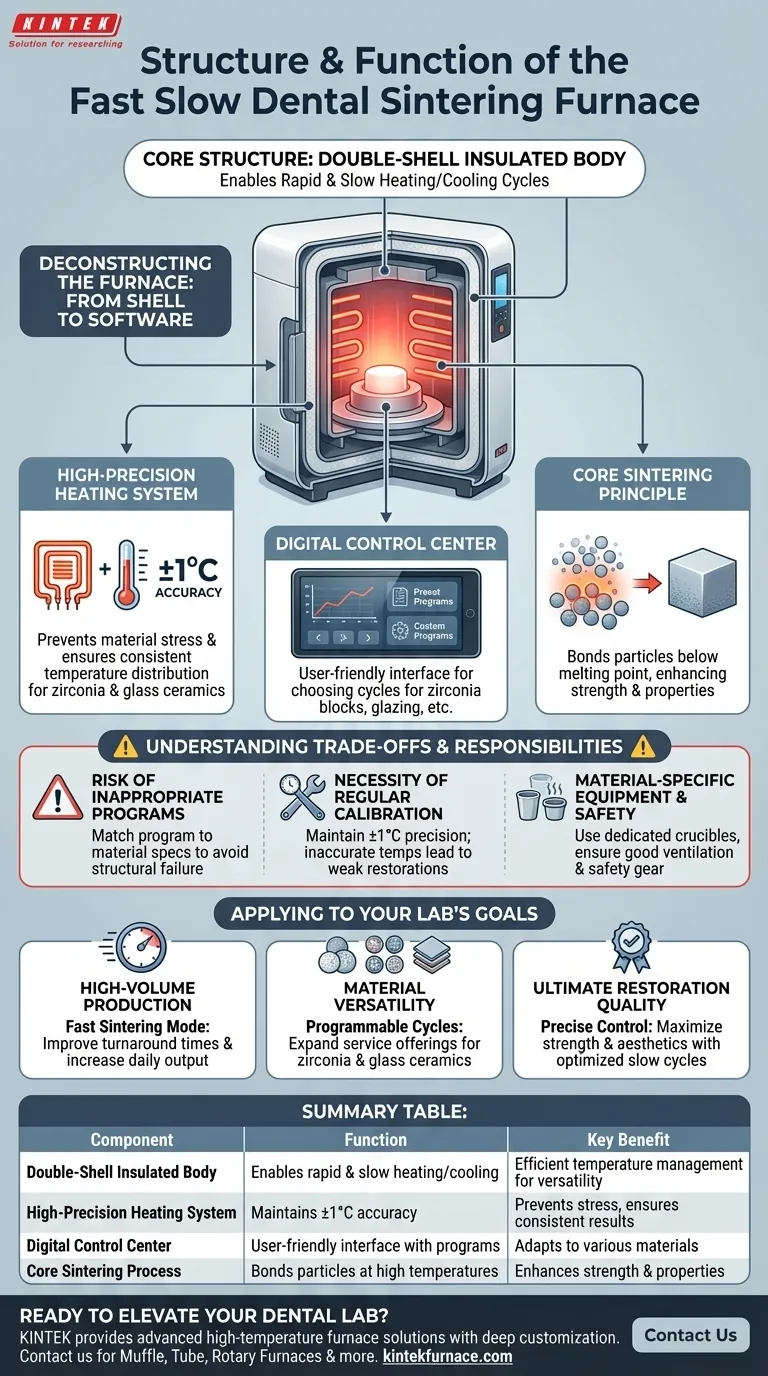

Deconstructing the Furnace: From Shell to Software

To truly understand the furnace, we must look at how its physical and digital components work together. Each element plays a critical role in producing a reliable and high-quality dental restoration.

The Double-Shell Insulated Body

The furnace's body uses two layers, creating a highly insulated chamber. This design is fundamental to its dual-mode operation.

It allows the furnace to reach and maintain extremely high temperatures efficiently for slow sintering, but it's also engineered to dissipate heat quickly when needed for fast sintering cycles.

The High-Precision Heating System

Inside the chamber, advanced heating elements are governed by a sophisticated temperature control system. This system maintains temperature with an accuracy of ±1°C.

This level of precision is not a luxury; it is essential for preventing material stress, deformation, or cracking. It ensures a consistent temperature distribution, which is critical for the structural integrity and longevity of zirconia and glass-ceramic restorations.

The Digital Control Center

The furnace is operated through a user-friendly touchscreen interface. This is the "brain" of the operation, giving the technician command over the powerful heating system.

Technicians can use multiple preset programs for common materials or create and save custom programs. This allows for perfect adaptation to the specific requirements of different materials, from zirconia blocks to glazing materials.

The Core Sintering Principle

The furnace's purpose is to facilitate sintering. This is a process where a material is heated to a high temperature, just below its melting point.

During this process, the individual particles of the material bond together, fusing into a dense, solid mass. This dramatically enhances the mechanical strength and physical properties of the final dental restoration.

Understanding the Trade-offs and Responsibilities

The flexibility of a dual-mode furnace introduces operational responsibilities that are critical for success. Ignoring them can negate the benefits of the advanced technology.

The Risk of Inappropriate Programs

The ability to choose between fast and slow cycles is a significant advantage, but it requires knowledge. Using a fast sintering program on a material specifically designed for a slow, multi-stage cycle can compromise its structural integrity and aesthetics.

You must always match the sintering program to the material manufacturer's specifications.

The Necessity of Regular Calibration

The furnace's ±1°C precision is only reliable if the system is properly maintained. Over time, temperature sensors and heating elements can drift.

Regular calibration is mandatory to ensure the temperature displayed on the screen is the true temperature inside the chamber. Inaccurate temperatures are a primary cause of failed or weak restorations.

Material-Specific Equipment and Safety

To prevent cross-contamination and ensure optimal results, you should use dedicated crucibles for different types of materials (e.g., one for zirconia, another for glass ceramics).

Furthermore, proper operational safety, including good ventilation to handle any potential outgassing and the use of protective equipment, is non-negotiable.

Applying This to Your Laboratory's Goals

Understanding the furnace's structure allows you to leverage its capabilities to meet specific clinical or business objectives.

- If your primary focus is high-volume production: The fast sintering mode is your key to improving turnaround times and increasing daily output.

- If your primary focus is material versatility: The programmable nature and validated cycles for both zirconia and glass ceramics allow you to expand your lab's service offerings.

- If your primary focus is ultimate restoration quality: The precise temperature control and the ability to run long, slow sintering programs are the tools you will use to maximize strength and aesthetics.

By mastering the relationship between its structure and its controls, you gain full command over the quality and efficiency of your dental restorations.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Double-Shell Insulated Body | Enables rapid and slow heating/cooling cycles | Efficient temperature management for versatility |

| High-Precision Heating System | Maintains temperature accuracy of ±1°C | Prevents material stress and ensures consistent results |

| Digital Control Center | User-friendly interface with preset and custom programs | Adapts to various materials like zirconia and glass ceramics |

| Core Sintering Process | Bonds particles at high temperatures for densification | Enhances strength and properties of dental restorations |

Ready to elevate your dental lab's capabilities? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to meet your unique experimental needs. Contact us today to discuss how our Fast Slow Dental Sintering Furnace can optimize your production, enhance restoration quality, and expand your service offerings!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Spark Plasma Sintering SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations