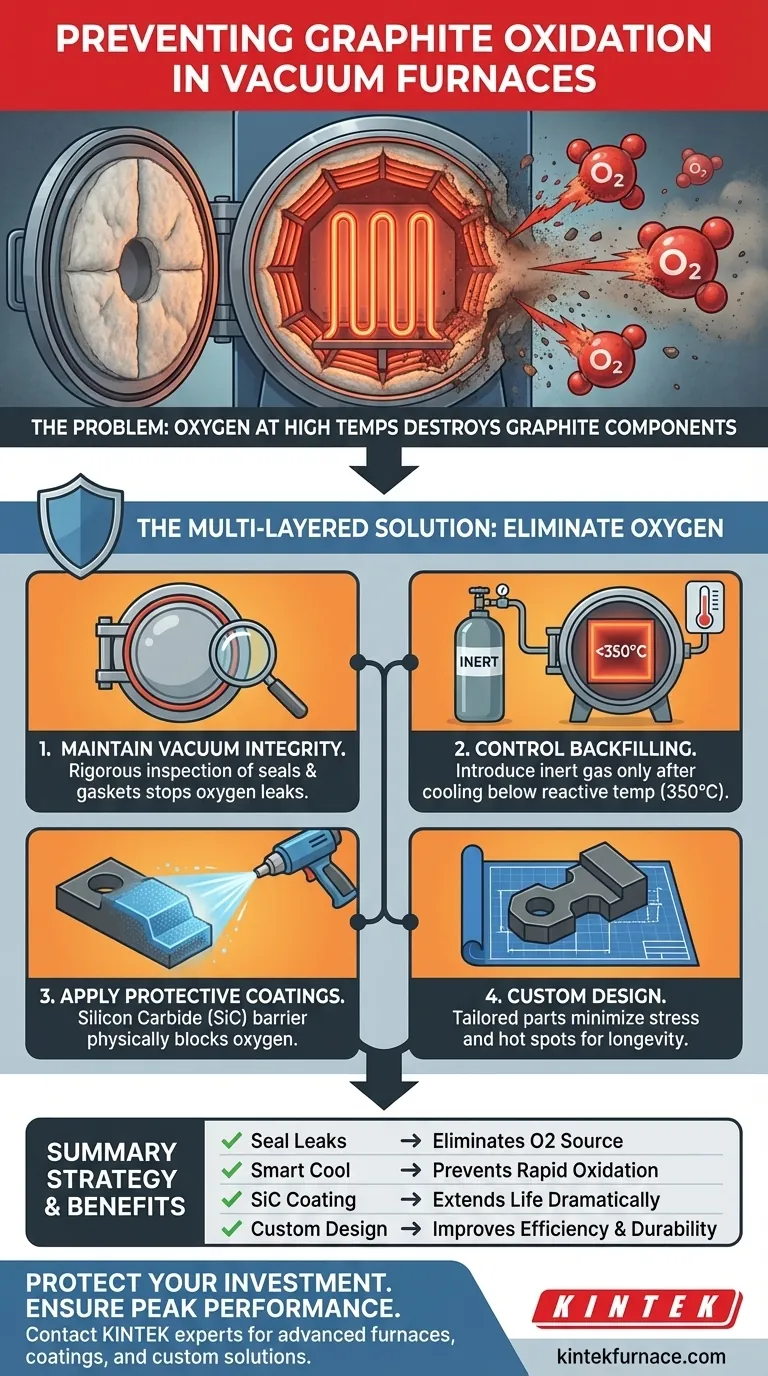

The most effective solution to prevent graphite oxidation in a vacuum furnace is to ensure the integrity of the vacuum itself. Oxidation is a chemical reaction requiring oxygen, so the primary goal is to eliminate its presence, especially at high temperatures. This is achieved through rigorous maintenance of the furnace's seals and gaskets and by controlling the backfill process to avoid introducing oxygen while components are still hot.

Graphite is an exceptional material for high-temperature furnace applications, but it is highly susceptible to damage from oxygen. Preventing oxidation is not a single action but a comprehensive strategy focused on maintaining a pure, oxygen-free environment throughout the entire heating and cooling cycle.

The Role of Graphite in Vacuum Furnaces

To understand why preventing oxidation is so critical, we must first appreciate the function of graphite within the furnace. It is not a minor component; it is central to the furnace's operation.

### Unmatched High-Temperature Performance

Graphite's primary advantage is its ability to maintain structural integrity and strength at extreme temperatures, capable of handling up to 3000°C (5432°F) in a vacuum or inert gas atmosphere.

### Critical Furnace Components

Graphite is used for the most thermally demanding parts of a furnace. These include:

- Heating Elements: The source of the furnace's heat.

- Insulation: Often in the form of graphite felt, it provides excellent thermal retention, keeping heat focused on the workload.

- Fixtures and Tooling: Racks, holders, and carriers that position the materials being heat-treated.

The Fundamental Cause: Oxygen Intrusion

Graphite's strength at high temperatures is only valid in an oxygen-free environment. The moment oxygen is introduced to a hot graphite surface, a destructive chemical reaction begins.

### The Oxidation Reaction

When hot, carbon atoms from the graphite react with oxygen molecules to form carbon monoxide (CO) or carbon dioxide (CO2) gas. This process physically erodes the graphite, causing it to lose mass and structural integrity.

### The Impact of Leaks

Even a small, seemingly insignificant leak in a door seal, gasket, or feedthrough can allow a continuous stream of air into the furnace. At operating temperature, this small amount of oxygen is enough to cause significant and cumulative damage to expensive graphite components over time.

### The Danger of Improper Cooling

A critical point of vulnerability is during the cooling cycle. If the vacuum is broken or an oxygen-rich gas is used for backfilling while the graphite is still at a reactive temperature (typically above 350°C / 650°F), rapid oxidation will occur.

Understanding the Trade-offs and Advanced Solutions

While procedural discipline is the first line of defense, it's also important to understand the inherent limitations of graphite and the advanced solutions available to mitigate them.

### The Finite Lifespan of Graphite

Even in a perfectly maintained furnace, graphite components have a finite service life. Repeated thermal cycling can cause mechanical stress, and microscopic impurities can create weak points. Prevention slows this degradation, but it cannot stop it entirely.

### Protective Coatings for Extended Life

A highly effective method for enhancing durability is the application of a protective coating. Silicon carbide (SiC) based coatings are a common and effective choice.

This coating forms a non-porous barrier on the graphite's surface, physically preventing oxygen from reaching it. This can dramatically extend the life of components, especially in furnaces that see frequent cycles or have a higher risk of minor leaks.

### The Value of Custom Design

For specialized applications, using custom-designed graphite parts can improve efficiency and durability. Parts tailored to a specific furnace's thermal dynamics and workload can minimize stress and hot spots, further prolonging their operational life.

How to Apply This to Your Operation

Your strategy should be tailored to your specific operational priorities, whether they are maximizing reliability, extending component life, or improving overall performance.

- If your primary focus is operational reliability: Enforce a strict maintenance schedule for all furnace seals, gaskets, and vacuum pumps, and ensure operators follow correct backfilling procedures with inert gas.

- If your primary focus is extending component lifespan: Invest in silicon carbide coatings for your most critical graphite components, such as heating elements and primary fixtures.

- If your primary focus is maximizing process efficiency: Evaluate your workload and consider commissioning custom-designed graphite fixtures that improve heat uniformity and reduce cycle times.

A disciplined, multi-layered approach to eliminating oxygen intrusion is the key to protecting your investment and ensuring consistent furnace performance.

Summary Table:

| Strategy | Key Action | Primary Benefit |

|---|---|---|

| Maintain Vacuum Integrity | Regular inspection of seals and gaskets. | Eliminates oxygen source, preventing the oxidation reaction. |

| Control Backfilling Process | Use inert gas only after cooling below 350°C. | Prevents rapid oxidation during the vulnerable cooling phase. |

| Apply Protective Coatings | Use Silicon Carbide (SiC) coatings on graphite. | Creates a physical barrier, dramatically extending component life. |

| Consider Custom Design | Tailor graphite parts to specific thermal dynamics. | Reduces stress and hot spots, improving longevity and efficiency. |

Protect your furnace investment and ensure peak performance.

Graphite oxidation is a costly and preventable problem. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, durable solutions for your high-temperature challenges. Our product line—including Vacuum & Atmosphere Furnaces, Muffle, Tube, and Rotary Furnaces—is backed by deep customization capabilities to precisely meet your unique requirements.

Whether you need components with protective SiC coatings, custom-designed fixtures to minimize stress, or expert advice on maintenance protocols, we are here to help.

Contact our experts today to discuss how we can extend the life of your graphite components and enhance your furnace's reliability.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does vacuum heat treating affect the grain structure of metal alloys? Achieve Precise Microstructure Control

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity