In dental technology, the burnout furnace serves one primary, non-negotiable function. It is specifically designed to eliminate a wax or 3D-printed resin pattern from a heat-resistant investment mold. This creates a perfectly clean and detailed negative space within the mold, which is then used to cast a metal alloy or press a ceramic material into the final shape of a dental restoration.

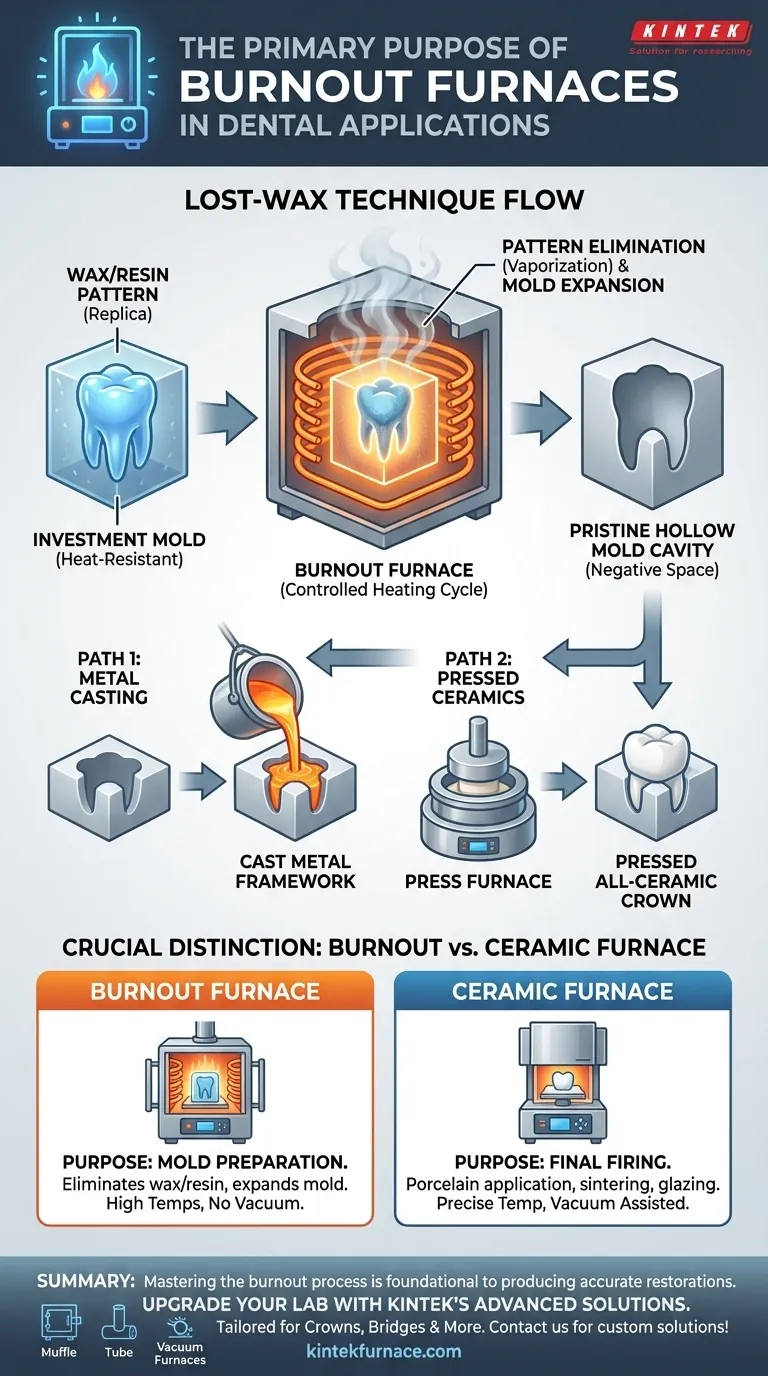

The central purpose of a burnout furnace is to execute the "burnout" phase of the lost-wax technique. It creates a pristine, empty mold cavity, which is the essential prerequisite for accurately casting metal frameworks or pressing all-ceramic crowns and bridges.

The Role of the Burnout Furnace in Fabrication

The creation of most indirect dental restorations, like crowns and bridges, relies on a precision process where the burnout furnace is a critical link in the chain. This process is a modern evolution of the ancient "lost-wax" technique.

Step 1: The Wax or Resin Pattern

First, a dental technician creates an exact replica of the final restoration using either dental wax or a castable, 3D-printed resin. This is known as the pattern.

Step 2: Investing the Pattern

The pattern is then encased in a plaster-like, heat-resistant material called investment. Once the investment hardens, it forms a solid block (the mold) with the pattern trapped inside.

Step 3: The Burnout Cycle

This is where the burnout furnace comes in. The investment mold is placed into the furnace and subjected to a carefully controlled heating cycle. This cycle accomplishes two goals:

- Pattern Elimination: It melts and completely vaporizes the wax or resin pattern, leaving no residue behind.

- Mold Expansion: It heats the investment mold to a specific temperature that causes it to expand slightly, compensating for the shrinkage of the metal alloy as it cools after casting.

After the cycle is complete, you are left with a hollow mold that is a perfect negative of the original pattern, ready for the final step.

Burnout for Casting vs. Pressing

The prepared mold can be used for two different fabrication methods.

Preparing Molds for Metal Casting

For Porcelain-Fused-to-Metal (PFM) crowns or full-metal restorations, the hot investment mold is placed in a casting machine. A molten dental alloy is then injected into the void, perfectly replicating the shape of the burned-out pattern.

Preparing Molds for Pressed Ceramics

For high-strength, all-ceramic restorations (like those made from lithium disilicate), the process is slightly different. A ceramic ingot and a plunger are placed into the hot mold. The entire assembly goes into a specialized press furnace, which presses the heat-softened ceramic into the void.

Understanding the Key Distinction: Burnout vs. Ceramic Furnace

A common point of confusion is the difference between a burnout furnace and a ceramic furnace. They are not interchangeable.

The Burnout Furnace: For Mold Preparation

The sole purpose of a burnout furnace is to prepare the investment mold. It is designed for the high temperatures and specific heating rates required to eliminate wax/resin and properly expand the investment material.

The Ceramic Furnace: For Firing Porcelain

A ceramic furnace, by contrast, is used to fire the final restoration. After a metal framework is cast, porcelain is applied and fired in a ceramic furnace to create the tooth-like appearance. This furnace is also used to sinter, glaze, and stain all-ceramic crowns to achieve the final esthetics. Ceramic furnaces often operate under vacuum, a feature burnout furnaces do not have.

Making the Right Choice for Your Goal

The equipment you use is defined by the stage of the fabrication process.

- If your primary focus is creating the mold for a cast metal framework: The burnout furnace is the essential tool for eliminating the wax pattern.

- If your primary focus is fabricating a pressed all-ceramic crown: You use the burnout furnace to create the mold and then a specialized press furnace to inject the ceramic.

- If your primary focus is applying porcelain to a framework or glazing a monolithic crown: You must use a ceramic furnace for its precise temperature control and vacuum capabilities.

Mastering the burnout process is foundational to producing accurate, well-fitting dental restorations.

Summary Table:

| Aspect | Key Information |

|---|---|

| Primary Purpose | Eliminate wax or resin patterns from investment molds to create clean cavities for dental restorations. |

| Key Process | Burnout phase in the lost-wax technique, involving controlled heating cycles. |

| Applications | Used for metal casting (e.g., PFM crowns) and ceramic pressing (e.g., all-ceramic crowns). |

| Distinction | Differs from ceramic furnaces, which are for firing porcelain and not mold preparation. |

Upgrade Your Dental Lab with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're fabricating crowns, bridges, or other restorations, our burnout and ceramic furnaces ensure accuracy, efficiency, and reliability.

Contact us today to discuss how we can tailor our solutions to enhance your dental restoration processes and boost productivity!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations