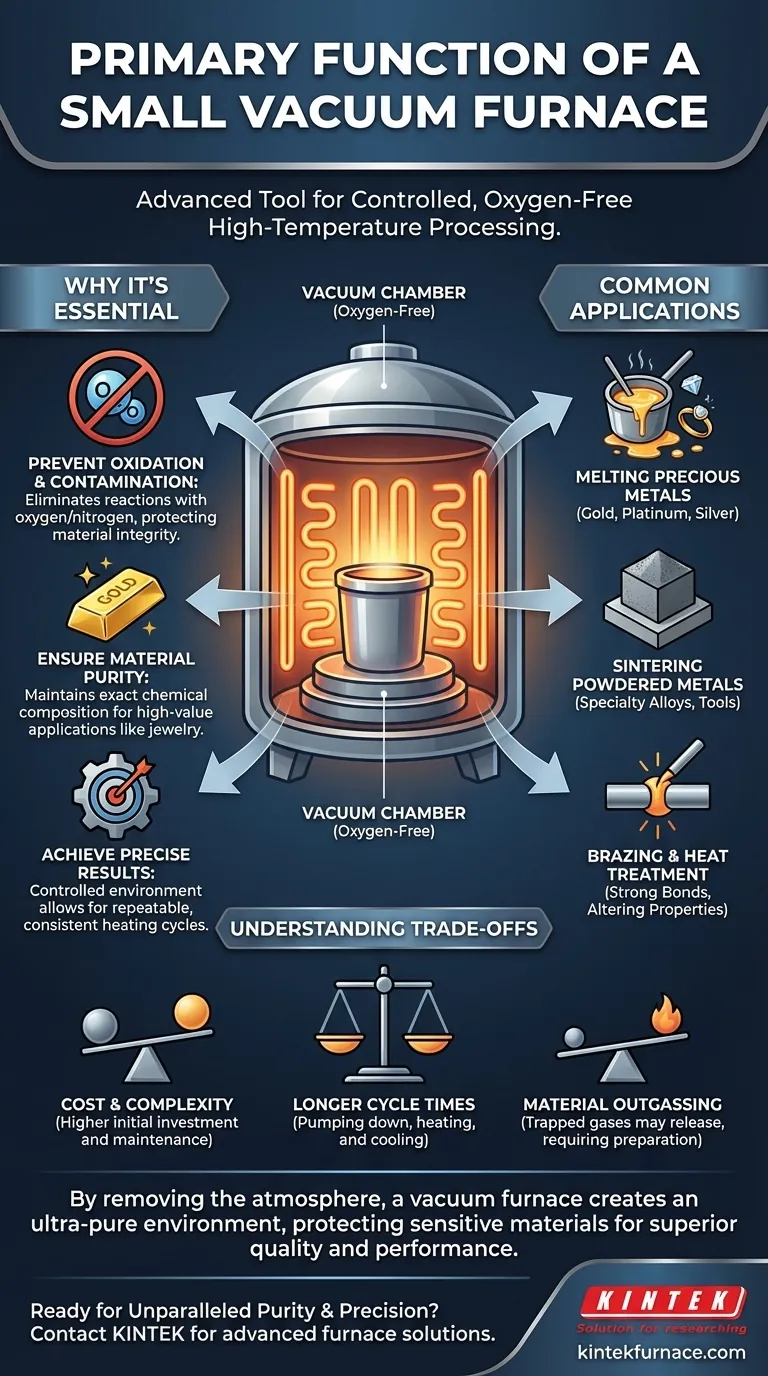

At its core, a small vacuum furnace is an advanced tool for melting or heat-treating high-value materials in a controlled, oxygen-free environment. Its primary function is to enable high-temperature processes for materials like precious metals, specialty alloys, or powdered metals without the risk of oxidation and contamination that would occur in open air.

The crucial insight is that the vacuum itself is not the process; it is the enabler. By removing the atmosphere, a vacuum furnace creates an ultra-pure environment that protects sensitive materials during heating, ensuring the final product's integrity, purity, and performance.

The Core Principle: Why a Vacuum is Essential

The decision to use a vacuum furnace stems from a fundamental problem in metallurgy: at high temperatures, most metals react aggressively with the oxygen and other gases present in the air. A vacuum furnace solves this by physically removing the atmosphere from the heating chamber.

Preventing Oxidation and Contamination

At elevated temperatures, reactive metals will readily bond with oxygen, forming an oxide layer on their surface. This oxidation can ruin the material's structural properties, electrical conductivity, or surface finish.

By pumping the air out of the chamber, the furnace removes the reactants—namely oxygen and nitrogen—preventing these unwanted chemical reactions from ever occurring.

Ensuring Material Purity

For applications like jewelry manufacturing with gold and platinum, or for creating specific scientific alloys, maintaining the exact chemical composition is critical.

A vacuum environment ensures no impurities from the atmosphere are introduced into the melt. This is also vital for sintering, where tiny metal powder particles must fuse cleanly without an oxide layer hindering the bond.

Achieving Precise and Consistent Results

The sealed, controlled environment of a vacuum furnace eliminates variables like air currents and atmospheric moisture. Combined with advanced temperature control systems, this allows for highly precise and repeatable heating and cooling cycles.

This consistency is essential for industrial processes where every part must meet identical specifications.

Common Applications for Small Vacuum Furnaces

While large vacuum furnaces are industrial workhorses, small models serve specialized, high-value niches where material quality is paramount.

Melting Precious Metals

This is a primary application for small vacuum furnaces, especially in jewelry manufacturing and dental labs. They provide the ideal environment for melting gold, silver, platinum, and palladium, ensuring maximum purity and a smooth, void-free cast.

Sintering Powdered Metals

Sintering is the process of fusing powdered material into a solid mass using heat, but without melting it. A vacuum is critical to prevent the microscopic powder particles from oxidizing, which would create a weak, defective final part. This is used for making items like high-strength carbide cutting tools.

Brazing and Heat Treatment

Brazing joins two components together using a filler metal, and a vacuum ensures an exceptionally clean and strong bond, free from oxidative interference. Similarly, heat treating (or annealing) in a vacuum can alter a metal's properties, such as increasing its strength or ductility, without damaging its surface.

Understanding the Trade-offs

A vacuum furnace is a powerful tool, but it is not always the right choice. Understanding its limitations is key to making an informed decision.

Cost and Complexity

Vacuum systems, including pumps, seals, and control instrumentation, make these furnaces significantly more expensive and complex to operate and maintain than a standard atmospheric furnace.

Longer Cycle Times

The process of pumping down the chamber to create a vacuum, running the heating cycle, and cooling the material adds considerable time. This makes vacuum furnaces better suited for high-value batch processing rather than high-volume, continuous work.

Material Outgassing

Certain materials can release trapped gases when placed under a vacuum at high temperatures, a phenomenon known as outgassing. This can interfere with the vacuum level or, in some cases, contaminate the part itself, requiring careful material preparation.

Making the Right Choice for Your Goal

Ultimately, the need for a vacuum furnace is dictated by your material and your desired outcome.

- If your primary focus is melting high-purity precious metals: A small vacuum furnace is the standard for preventing material loss and ensuring the highest quality for jewelry or investment-grade bullion.

- If your primary focus is creating specialty alloys or R&D: The controlled, inert environment of a vacuum furnace is necessary to achieve uncontaminated and repeatable results for material science.

- If your primary focus is producing high-performance components: For processes like brazing or sintering where bond strength and material integrity are non-negotiable, a vacuum furnace is the superior choice.

By understanding that the vacuum's function is protection, you can leverage this technology to achieve results that are impossible in a conventional furnace.

Summary Table:

| Function | Key Benefit | Common Applications |

|---|---|---|

| Melting | Prevents oxidation, ensures purity | Jewelry, dental labs (gold, platinum) |

| Sintering | Fuses powders without contamination | Carbide tools, specialty alloys |

| Brazing & Heat Treatment | Creates clean, strong bonds | High-performance components, R&D |

Ready to achieve unparalleled purity and precision in your lab processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're melting precious metals or sintering powdered metals, our vacuum furnaces deliver consistent, contamination-free results. Contact us today to discuss how we can enhance your laboratory's efficiency and outcomes!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How are parts loaded into a vacuum furnace? Ensure Precision and Efficiency in Your Process

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How do vacuum furnaces contribute to long-term cost savings? Reduce Costs with Efficiency and Quality