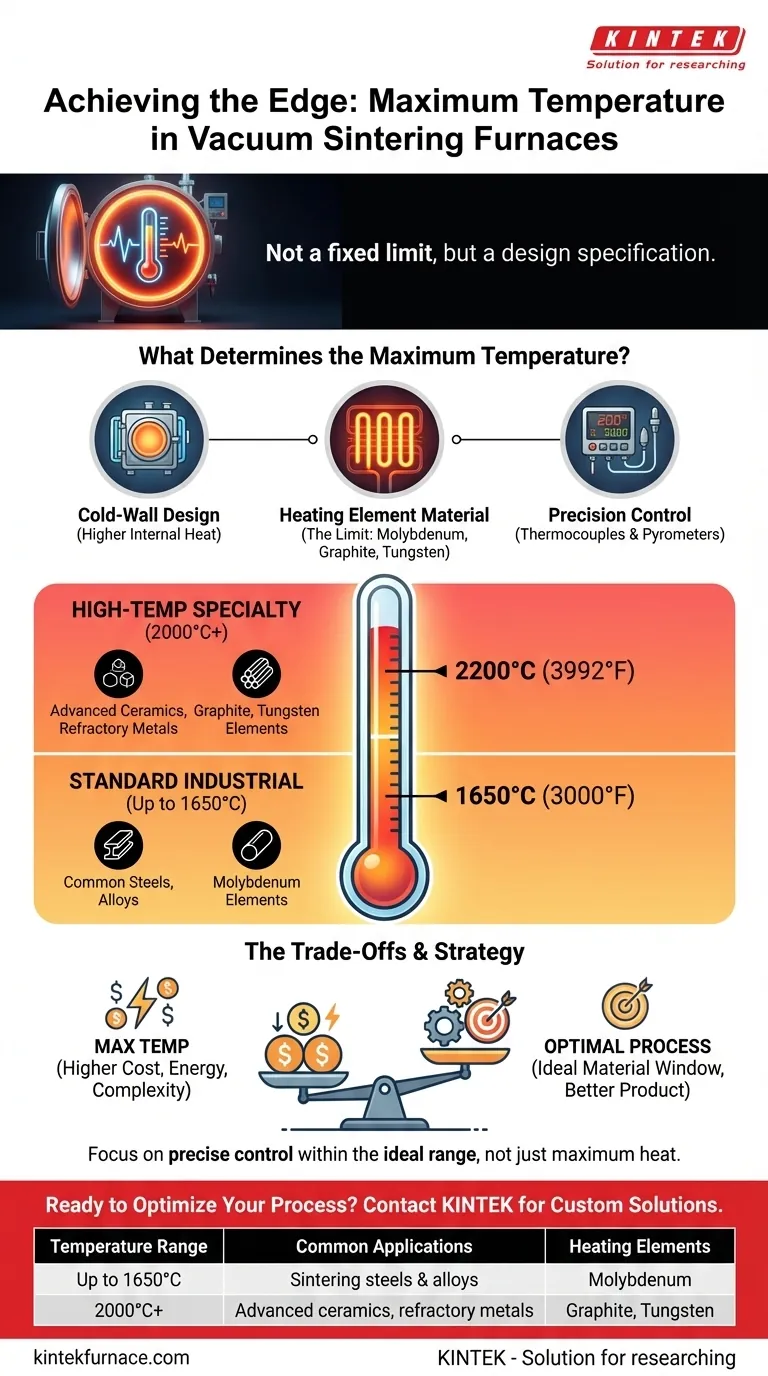

While some high-performance vacuum sintering furnaces can reach temperatures up to 2200°C (3992°F), this is not a universal maximum. The achievable temperature is fundamentally dependent on the furnace's specific design, the materials used for its heating elements, and its intended industrial application. There is no single "max temp," but rather a spectrum of capabilities tailored to different processes.

The maximum temperature of a vacuum sintering furnace is not a fixed value but a key design specification. It is dictated by the furnace's construction and components, meaning the critical question is not "how hot can it get?" but "what temperature range does my specific material require?"

What Determines a Furnace's Maximum Temperature?

The temperature rating of a vacuum furnace is a result of deliberate engineering choices. Several key factors work together to define its operational limits and overall performance.

The Impact of Furnace Design: Cold Wall vs. Hot Wall

The most significant factor is the furnace's core architecture. Cold-wall furnaces are the standard for high-temperature applications.

In this design, the heating elements are located inside the vacuum chamber, surrounded by heat shields. A cooling jacket with circulating water on the exterior of the chamber wall keeps the vessel itself cool, enabling much higher internal temperatures, faster heating and cooling cycles, and greater temperature uniformity.

The Critical Role of Heating Elements

The material used for the heating elements directly limits the furnace's maximum temperature. The element must be able to withstand extreme heat without degrading.

Common materials include:

- Molybdenum: Used for temperatures generally up to 1650°C (3000°F).

- Graphite or Tungsten: Required for higher-temperature applications, allowing furnaces to reliably operate at 2000°C (3632°F) and beyond.

Temperature Control and Measurement Systems

To operate at these extremes, furnaces require sophisticated control systems. A combination of armored thermocouples (for lower ranges) and optical fiber pyrometers (for high ranges) are used to continuously measure the temperature.

This data is fed to an intelligent controller that adjusts the power supply, ensuring the temperature precisely follows the programmed heating profile with uniformity often within +/- 5°C.

Understanding Common Temperature Ranges

Vacuum furnaces are typically offered in different series, each designed for a specific class of materials and processes.

Standard Industrial Furnaces (Up to 1650°C)

The majority of industrial applications, including the sintering of many metals and alloys, fall into this range. Furnaces are commonly available with maximum temperatures of 1315°C (2400°F) or 1650°C (3000°F).

High-Temperature Specialty Furnaces (2000°C+)

Achieving temperatures of 2000°C, 2200°C, or even higher requires a specialized furnace. These units use graphite or tungsten elements and are reserved for processing advanced materials.

Applications include sintering non-oxide ceramics, refractory metals like tungsten, and creating other high-purity, high-performance components.

Understanding the Trade-offs

Pursuing the highest possible temperature comes with significant trade-offs that are critical to consider.

Increased Cost and Complexity

Higher temperature ratings demand more exotic and expensive materials for heating elements, insulation, and internal structures. This substantially increases both the initial purchase price and the long-term maintenance costs of the furnace.

Higher Energy Consumption

The power required to reach and maintain temperatures above 2000°C is significantly greater than for standard-range furnaces. This translates directly to higher operational costs and greater infrastructure requirements.

Process Optimization vs. Maximum Temperature

The goal of sintering is to achieve optimal material properties, which rarely occurs at the absolute maximum temperature a furnace can produce. Using excessive heat can be detrimental to the final product. The focus should be on precise control within the material's ideal processing window.

Making the Right Choice for Your Application

Selecting a furnace is about matching its capabilities to your specific process goals.

- If your primary focus is sintering common steels and alloys: A furnace with a maximum temperature around 1315°C to 1650°C is typically sufficient and more cost-effective.

- If your primary focus is processing advanced ceramics or refractory metals: You will need a specialized high-temperature furnace capable of reaching 2000°C or higher, likely featuring graphite elements.

- If your primary focus is process purity and consistency: Prioritize a cold-wall furnace with an advanced digital control system to ensure low contamination and excellent temperature uniformity.

Ultimately, the goal is not to find the furnace with the highest possible temperature, but the one with the precise range and control your specific material requires.

Summary Table:

| Temperature Range | Common Applications | Heating Elements |

|---|---|---|

| Up to 1650°C | Sintering common steels and alloys | Molybdenum |

| 2000°C and above | Processing advanced ceramics, refractory metals | Graphite, Tungsten |

Need a high-temperature furnace tailored to your lab's unique requirements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise temperature control and performance for your specific materials and processes. Contact us today to discuss how our furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?