In dentistry, sintering is a high-temperature firing process that transforms a soft, chalk-like ceramic block into a dense, final-strength restoration. It is the essential final step in fabricating modern dental prosthetics, most notably those made from zirconia, by fusing individual ceramic particles into a solid, monolithic structure.

Sintering is not merely a heating process; it is a controlled transformation. It's the critical step that imparts the necessary strength, durability, and esthetic properties to advanced ceramic materials like zirconia, making them suitable for crowns, bridges, and implants.

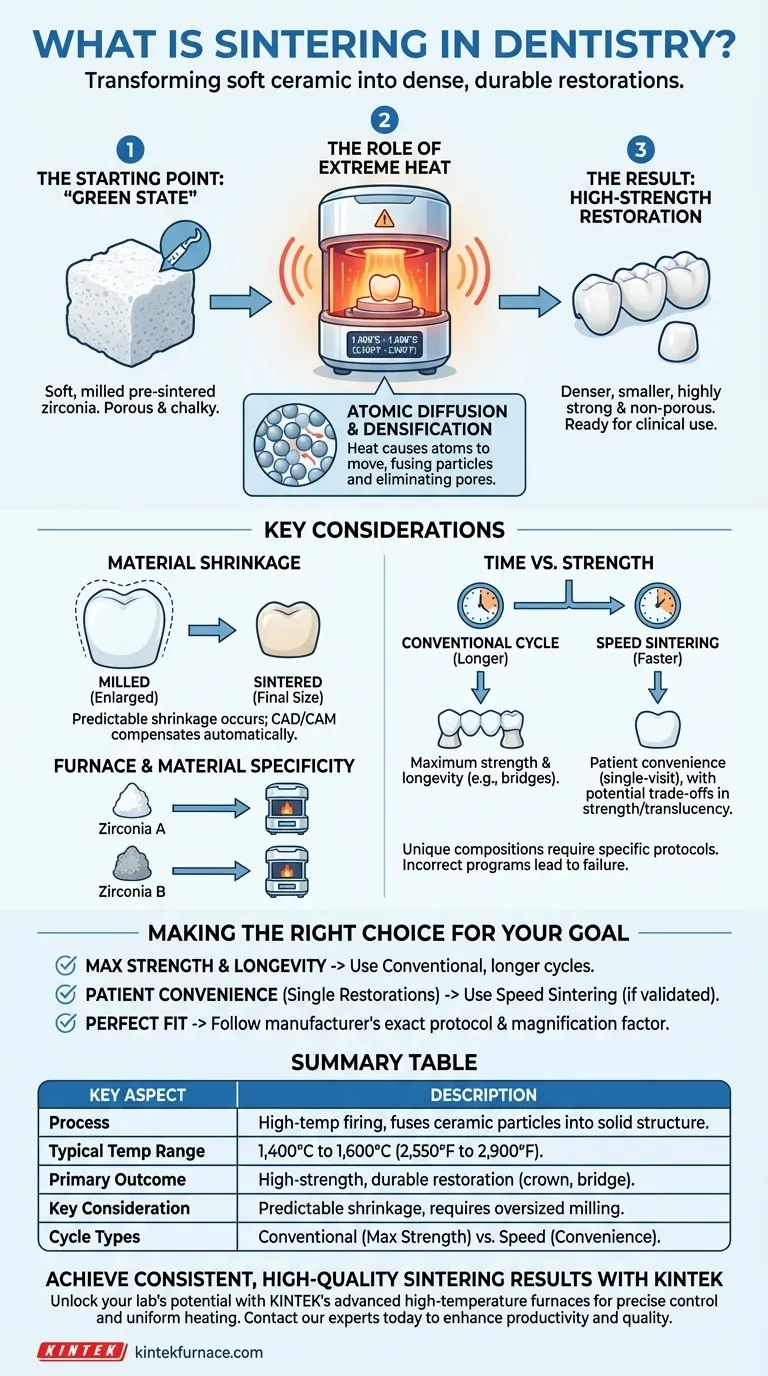

The Core Mechanism: From Powder to Prosthesis

Sintering is a fascinating process of material science that happens on a microscopic level, turning a fragile, milled shape into a durable medical device.

The Starting Point: A "Green State"

A dental restoration like a crown begins its life milled from a block of pre-sintered zirconia. In this initial "green" or "chalky" state, the material is soft enough for a dental mill to shape it with precision and relative ease.

The Role of Extreme Heat

The milled restoration is placed into a specialized sintering furnace. These furnaces are engineered to reach extremely high temperatures, typically between 1,400°C and 1,600°C (2,550°F and 2,900°F), using robust heating elements.

Atomic Diffusion and Densification

This intense heat provides the energy needed for atomic diffusion. The atoms at the edges of the individual ceramic particles become agitated and begin to move across the boundaries, effectively fusing the particles together. This eliminates the pores between particles, leading to a much denser and more compact structure.

The Result: A High-Strength Restoration

The final result is a restoration that is significantly smaller, incredibly dense, and possesses the high strength required to withstand the forces of chewing. The process fundamentally changes the material's physical properties from soft and porous to hard and non-porous.

Understanding the Key Considerations

While the concept is straightforward, the practical application of sintering requires precision and an understanding of its inherent trade-offs.

Material Shrinkage is Unavoidable

As the particles fuse and the pores are eliminated, the entire restoration undergoes significant and predictable shrinkage. To compensate, the restoration is initially designed and milled in an enlarged state. CAD/CAM software automatically calculates this magnification factor to ensure the final sintered crown is the exact size and shape required.

Time vs. Strength: The Speed Sintering Factor

Conventional sintering cycles can take several hours. Newer "speed sintering" cycles drastically reduce this time, enabling the delivery of single-visit or next-day restorations. This offers immense convenience for the patient and clinic.

However, there is often a trade-off. While suitable for many cases (like single crowns), these accelerated cycles may result in slightly lower final strength or different translucency compared to longer, traditional programs.

Furnace and Material Specificity

Sintering is not a one-size-fits-all process. Different types of zirconia have unique chemical compositions that require specific temperatures and heating/cooling rates. Using the incorrect furnace program for a given material can lead to a weak, fractured, or esthetically poor restoration.

Making the Right Choice for Your Goal

Understanding the nuances of sintering empowers dental professionals to optimize outcomes based on the clinical situation.

- If your primary focus is maximum strength and longevity: Utilize a conventional, longer sintering cycle, which is especially critical for multi-unit bridges or cases under high occlusal stress.

- If your primary focus is patient convenience for single restorations: Speed sintering is a powerful and effective tool, provided the zirconia material is explicitly validated for that specific rapid cycle.

- If your primary focus is a perfect fit: Always follow the manufacturer's exact protocol, matching the milling magnification factor to the shrinkage of the chosen material and its corresponding sintering program.

Mastering the sintering process is fundamental to unlocking the full clinical potential of modern ceramic dental restorations.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | High-temperature firing that fuses ceramic particles (e.g., zirconia) into a solid, dense structure. |

| Typical Temperature Range | 1,400°C to 1,600°C (2,550°F to 2,900°F). |

| Primary Outcome | Creates a high-strength, durable dental restoration (crown, bridge, implant). |

| Key Consideration | Predictable shrinkage occurs; the restoration must be milled oversized to compensate. |

| Cycle Types | Conventional: Longer cycle for maximum strength. Speed Sintering: Faster cycle for patient convenience. |

Achieve Consistent, High-Quality Sintering Results with KINTEK

Unlock the full potential of your dental lab's ceramic restorations. KINTEK's advanced high-temperature sintering furnaces are engineered for precise temperature control and uniform heating, ensuring your zirconia crowns and bridges achieve optimal strength and esthetics every time. Our strong deep customization capability allows us to tailor furnace solutions to your specific workflow, whether you prioritize the ultimate material strength from conventional cycles or the efficiency of speed sintering.

Contact our experts today to discuss how our Muffle, Tube, Vacuum & Atmosphere Furnaces can enhance your lab's productivity and restoration quality.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision