In short, Plasma Enhanced Chemical Vapor Deposition (PECVD) is a modern evolution of traditional Chemical Vapor Deposition (CVD). The fundamental difference is its energy source. Instead of relying solely on high heat to drive the chemical reaction, PECVD uses an energized gas, or plasma, to deposit thin films at significantly lower temperatures.

The core distinction is not the goal—both techniques deposit thin films from a gas—but the method of activation. Traditional CVD uses intense heat to break down gases, while PECVD uses an energy-efficient plasma. This allows PECVD to operate at lower temperatures, dramatically expanding its applications and often improving film quality.

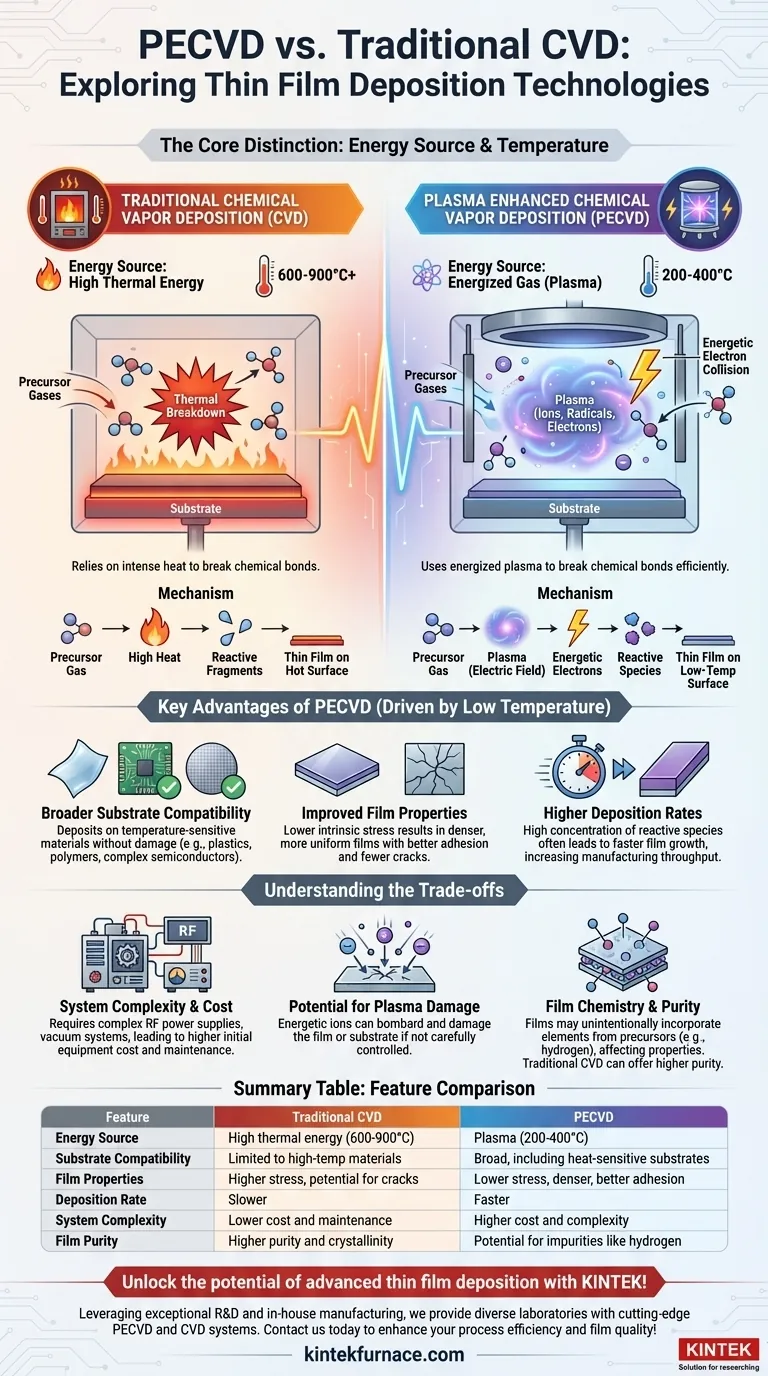

The Core Mechanism: Heat vs. Plasma

To understand why you would choose one method over the other, you must first understand how each one works at a chemical level. The goal is to break apart stable precursor gases and encourage them to react and form a solid film on a surface (the substrate).

How Traditional CVD Works

Traditional CVD is conceptually simple. Precursor gases are flowed over a substrate that has been heated to very high temperatures, often in the range of 600-900°C or higher.

This intense thermal energy provides the activation energy needed to break the chemical bonds in the precursor gas molecules. The resulting reactive fragments then settle on the hot surface, forming the desired thin film.

How PECVD Works

PECVD achieves the same outcome without extreme heat. It operates within a vacuum chamber where an electric field is used to ionize the precursor gases, turning them into a plasma.

This plasma is a soup of ions, radicals, and highly energetic electrons. These energetic electrons collide with the gas molecules, breaking their bonds far more efficiently than heat alone. This allows the substrate to remain at a much lower temperature, typically between 200-400°C, while still achieving a high-quality film deposition.

Key Advantages Driven by Low Temperature

The shift from thermal energy to plasma energy is not just a technical curiosity; it produces several critical, real-world advantages.

Broader Substrate Compatibility

This is the most significant benefit of PECVD. Many advanced materials, such as plastics, polymers, or complex semiconductor devices with multiple layers, cannot withstand the high temperatures of traditional CVD.

PECVD’s low-temperature process makes it possible to deposit high-quality films on these temperature-sensitive substrates without causing damage, warping, or degradation.

Improved Film Properties

High temperatures introduce thermal stress into a film as it cools, which can lead to cracks or poor adhesion.

Because PECVD operates at lower temperatures, it produces films with less intrinsic stress. This results in denser, more uniform coatings that are less prone to cracking and adhere better to the substrate.

Higher Deposition Rates

The plasma creates a much higher concentration of reactive chemical species than is typically possible with thermal methods at comparable temperatures.

This high density of "ready-to-react" molecules often leads to faster film growth. This increases throughput, which is a critical factor in manufacturing environments like semiconductor fabrication and solar cell production.

Understanding the Trade-offs

While powerful, PECVD is not a universal replacement for traditional CVD. Choosing the right method requires understanding its limitations.

System Complexity and Cost

A PECVD system is inherently more complex than a thermal CVD furnace. It requires radio-frequency (RF) power supplies, impedance matching networks, and more sophisticated vacuum chamber designs to generate and sustain the plasma. This translates to higher initial equipment cost and maintenance.

Potential for Plasma Damage

The same energetic ions that drive the reaction can also bombard the film and substrate surface. If not carefully controlled, this bombardment can introduce defects or damage into the material's crystal structure.

Film Chemistry and Purity

PECVD films can sometimes unintentionally incorporate elements from the precursor gases, such as hydrogen. While this is sometimes a desirable feature (known as passivation), it can also be an impurity that alters the film's electrical or optical properties. High-temperature CVD can sometimes produce purer, more crystalline films for specific applications.

Making the Right Choice for Your Process

Your decision should be guided by your specific material constraints and desired outcome.

- If your primary focus is compatibility with heat-sensitive substrates: PECVD is the clear and often only choice due to its low-temperature operation.

- If your primary focus is achieving the highest possible film purity and crystallinity (e.g., for epitaxy): Traditional high-temperature CVD may still be superior for certain materials where thermal energy promotes better lattice formation.

- If your primary focus is high throughput on robust substrates: PECVD often provides higher deposition rates, but you must balance this against the higher equipment complexity and cost.

Understanding this fundamental trade-off between thermal and plasma energy empowers you to select the precise deposition tool for your material and performance goals.

Summary Table:

| Feature | Traditional CVD | PECVD |

|---|---|---|

| Energy Source | High thermal energy (600-900°C) | Plasma (200-400°C) |

| Substrate Compatibility | Limited to high-temperature materials | Broad, including heat-sensitive substrates |

| Film Properties | Higher stress, potential for cracks | Lower stress, denser, better adhesion |

| Deposition Rate | Slower | Faster |

| System Complexity | Lower cost and maintenance | Higher cost and complexity |

| Film Purity | Higher purity and crystallinity | Potential for impurities like hydrogen |

Unlock the potential of advanced thin film deposition with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with cutting-edge PECVD and CVD systems, including our full product line of Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures solutions tailored to your unique experimental needs, whether you're working with semiconductors, solar cells, or temperature-sensitive materials. Contact us today to discuss how our high-temperature furnace solutions can enhance your process efficiency and film quality!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings