At its core, a vacuum furnace is a specialized high-temperature furnace that processes materials inside a vacuum. By removing air and other gases, it creates a highly controlled environment, preventing unwanted chemical reactions like oxidation. This allows for superior heat treatment, joining, and sintering of materials that would be damaged or degraded if heated in a normal atmosphere.

The critical difference between a vacuum furnace and a conventional furnace isn't just temperature; it's control over the atmosphere. Removing the air eliminates oxidation and contamination, enabling high-purity processes and resulting in materials with superior structural integrity and surface finish.

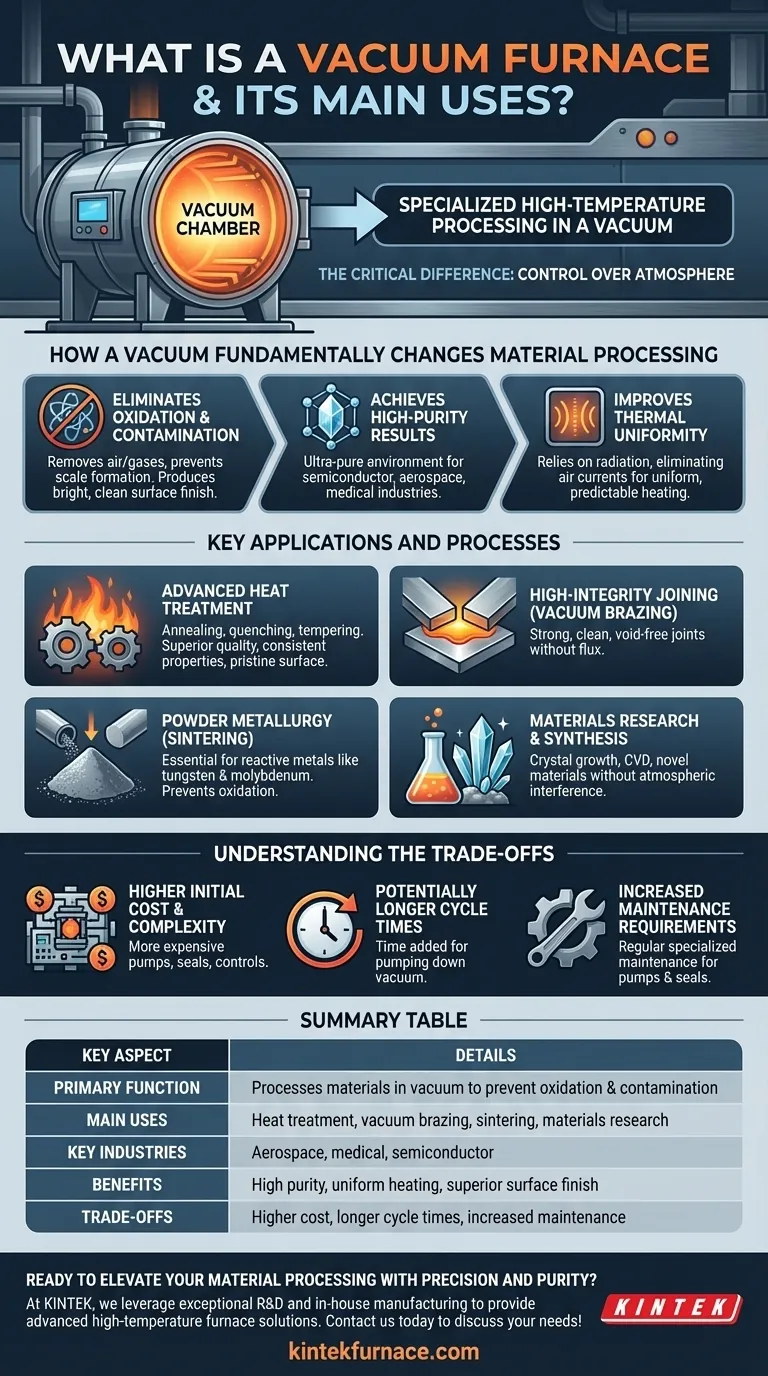

How a Vacuum Fundamentally Changes Material Processing

To understand the purpose of a vacuum furnace, you must first recognize the problem it solves. At high temperatures, most materials—especially metals—react aggressively with the oxygen in the air. This reaction, called oxidation, forms a layer of scale on the surface, alters material properties, and can compromise the final product.

Eliminating Oxidation and Contamination

A vacuum furnace directly addresses this by pumping the atmosphere out of the heating chamber. The absence of air and other gases prevents oxidation, even at extreme temperatures. This is crucial for producing parts with a bright, clean surface finish without the need for secondary cleaning operations.

Achieving High-Purity Results

Beyond just oxygen, the vacuum removes other potential contaminants present in the air. This creates an ultra-pure environment essential for manufacturing sensitive components in the semiconductor, aerospace, and medical industries. It allows for processes that are simply not possible in a standard furnace.

Improving Thermal Uniformity

In a conventional furnace, heat is transferred through conduction, convection, and radiation. The air currents involved in convection can lead to uneven heating and hot spots. By removing the air, a vacuum furnace eliminates heat loss through convection, relying primarily on radiation. This results in highly uniform and predictable heating of the entire part.

Key Applications and Processes

The controlled environment of a vacuum furnace enables several specialized industrial processes that demand precision and purity.

Advanced Heat Treatment

While standard furnaces also perform heat treatment, a vacuum furnace offers superior quality. Processes like annealing, quenching, and tempering are performed to alter a material's hardness and ductility. Doing so in a vacuum ensures the material's surface remains pristine and its properties are consistent throughout.

High-Integrity Joining (Vacuum Brazing)

Brazing is a process that joins two pieces of metal using a filler material that melts at a lower temperature than the base metals. In a vacuum, this process creates exceptionally strong, clean, and void-free joints without the need for corrosive fluxes, which can become trapped and cause failures later.

Powder Metallurgy (Sintering)

Sintering is the process of heating compacted metal powders to bond the particles together, forming a solid part. For reactive or refractory metals like tungsten and molybdenum, a vacuum is essential to prevent them from being destroyed by oxidation during this high-temperature process.

Materials Research and Synthesis

The pristine environment of a vacuum furnace is ideal for research and development. It is used for growing pure crystals, synthesizing novel materials through processes like chemical vapor deposition (CVD), and characterizing material properties without atmospheric interference.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for all heating applications. It involves specific trade-offs compared to simpler atmospheric furnaces.

Higher Initial Cost and Complexity

The components required to create and maintain a vacuum—including pumps, seals, and control systems—make these furnaces more complex and expensive than their atmospheric counterparts.

Potentially Longer Cycle Times

The process of pumping the chamber down to the required vacuum level adds time to each cycle. For high-volume production of non-sensitive parts, this can be a significant throughput bottleneck.

Increased Maintenance Requirements

Vacuum pumps, chamber seals, and instrumentation require regular, specialized maintenance to ensure the integrity of the vacuum. Neglecting this maintenance can lead to leaks, contamination, and failed processing runs.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your material, your process requirements, and your economic constraints.

- If your primary focus is high purity and oxidation prevention: A vacuum furnace is essential for processing reactive metals, creating clean brazed joints, or performing sensitive materials research.

- If your primary focus is general-purpose heat treatment on non-reactive materials: A simpler and more cost-effective atmospheric box furnace is often a sufficient and practical choice.

- If your primary focus is maximizing throughput for basic processes: The added cycle time of a vacuum furnace may be a disadvantage, making a continuous or batch atmospheric furnace more suitable.

Ultimately, choosing a vacuum furnace is a decision to invest in control over the processing environment to achieve results that are otherwise unattainable.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Function | Processes materials in a vacuum to prevent oxidation and contamination |

| Main Uses | Heat treatment, vacuum brazing, sintering, materials research |

| Key Industries | Aerospace, medical, semiconductor |

| Benefits | High purity, uniform heating, superior surface finish |

| Trade-offs | Higher cost, longer cycle times, increased maintenance |

Ready to elevate your material processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like aerospace, medical, and semiconductor. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Don't let oxidation or contamination hold you back—contact us today to discuss how our vacuum furnaces can deliver superior results for your applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today