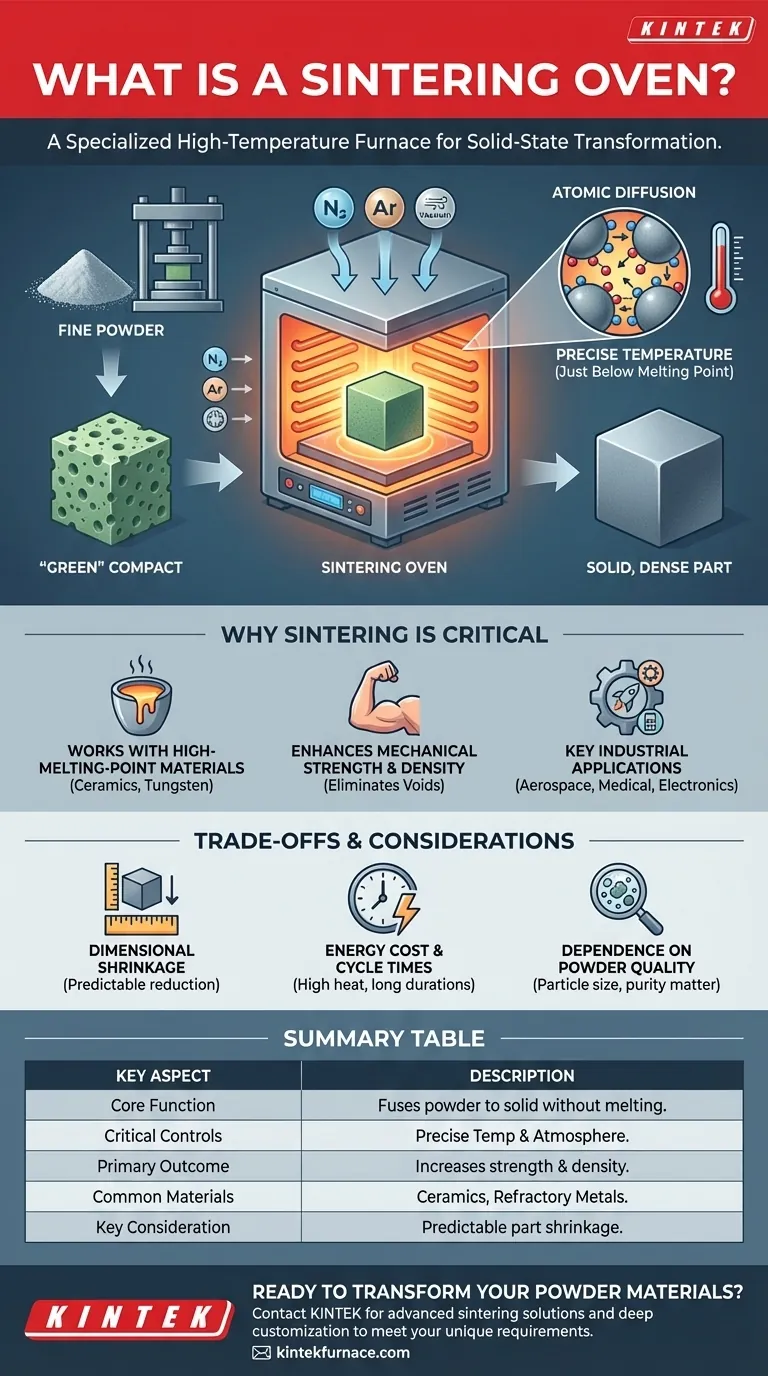

At its core, a sintering oven is a specialized high-temperature furnace used to transform a compacted powder into a solid, dense object. The process, known as sintering, involves heating the material to a precise temperature just below its melting point. This encourages the individual particles to fuse together, dramatically increasing the part's mechanical strength, density, and in some cases, its translucency, without ever liquefying the material.

A sintering oven is not for melting. It is a precision tool for a solid-state transformation, using controlled heat and atmosphere to bond loose particles into a strong, engineered component at a microscopic level.

The Fundamental Principle: How Sintering Works

Sintering is a process driven by atomic-level mechanics. The oven's role is to provide the perfect environment for this transformation to occur reliably and repeatably.

From Powder to "Green" Compact

The process begins not with a liquid or solid block, but with a fine powder. This powder is first pressed or molded into the desired shape, creating what is known as a "green compact." This initial form is fragile and porous, holding its shape only loosely.

The Role of Atomic Diffusion

Inside the sintering oven, heat provides the energy for atoms on the surfaces of adjacent powder particles to move, or diffuse. This atomic movement closes the gaps and pores between particles, creating strong metallurgical or chemical bonds where they touch. The result is a single, dense, and cohesive mass.

Precision Temperature Control

The most critical function of a sintering oven is its ability to maintain a stable temperature just below the material's melting point. If the temperature is too low, diffusion will not occur effectively. If it's too high, the material will melt, destroying the intended microstructure and resulting in a failed part.

Controlling the Atmosphere

Many materials, especially metals, will oxidize or react undesirably at high temperatures. Sintering ovens often operate with a controlled atmosphere—such as a vacuum, nitrogen, or argon—to prevent these unwanted chemical reactions and ensure the purity and integrity of the final product.

Why Sintering is a Critical Manufacturing Process

Sintering is not just an alternative to melting and casting; it is an enabling technology that makes the production of certain high-performance materials possible.

Working with High-Melting-Point Materials

Sintering is essential for processing materials with extremely high melting points, such as ceramics, tungsten, and molybdenum. Melting and casting these materials is often impractical or prohibitively expensive, making sintering the primary method for creating durable parts.

Enhancing Mechanical Strength and Density

The core purpose of sintering is to eliminate the voids between powder particles. This densification process directly leads to a significant increase in the final part's strength, hardness, and durability, making it suitable for demanding applications.

Key Industrial Applications

The unique capabilities of sintering make it indispensable across many advanced industries. It is used to produce everything from aerospace turbine components and automotive engine parts to durable medical implants and electronic substrates.

Understanding the Trade-offs and Considerations

While powerful, the sintering process involves critical factors that must be managed for success.

Dimensional Shrinkage

As the pores between particles close up, the overall part will shrink. This shrinkage is a natural and expected part of the process, but it must be precisely calculated and compensated for in the initial design of the "green compact" to achieve the correct final dimensions.

Energy Cost and Cycle Times

Maintaining extremely high temperatures for extended periods requires a significant amount of energy. Sintering cycles can last for many hours, making it a potentially costly and time-consuming manufacturing step compared to other methods.

Dependence on Powder Quality

The final properties of a sintered component are directly tied to the characteristics of the initial powder. Factors like particle size, shape, and purity must be tightly controlled to ensure consistent and reliable results.

Making the Right Choice for Your Goal

Understanding when and why to use sintering is key to leveraging its advantages for your specific engineering challenge.

- If your primary focus is creating parts from high-temperature materials: Sintering is often the only viable method for processing ceramics or refractory metals that cannot be easily cast.

- If your primary focus is controlling final part density or porosity: The sintering process offers unique control over the microstructure, enabling the production of specialized items like filters or self-lubricating bearings.

- If your primary focus is achieving maximum strength and durability: Sintering transforms a weak powder compact into a dense, robust component suitable for high-stress applications.

Ultimately, a sintering oven is a powerful tool that transforms simple powders into precisely engineered components, solving challenges that traditional manufacturing methods cannot address.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Fuses powder particles into a solid, dense mass without melting. |

| Critical Controls | Precise temperature (just below melting point) & controlled atmosphere (vacuum, N₂, Ar). |

| Primary Outcome | Dramatically increases mechanical strength, hardness, and density. |

| Common Materials | Ceramics, refractory metals (Tungsten, Molybdenum), metal alloys. |

| Key Consideration | Predictable part shrinkage occurs during the process. |

Ready to transform your powder materials into high-performance components?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature sintering solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique material and process requirements.

Contact our experts today to discuss how a KINTEK sintering oven can enhance your manufacturing process and deliver the strength and durability your applications demand.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Spark Plasma Sintering SPS Furnace

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations