In the field of dental prosthetics, a porcelain furnace is a specialized, high-temperature oven used in dental laboratories and clinics. Its primary function is to fire, sinter, and glaze ceramic materials, transforming them into strong, durable, and aesthetically pleasing dental restorations such as crowns, bridges, veneers, and inlays.

The challenge in modern dentistry is creating restorations that are both mechanically robust and visually indistinguishable from natural teeth. A porcelain furnace is the critical tool that achieves this by applying precisely controlled heat to fuse ceramic particles into a solid, life-like structure.

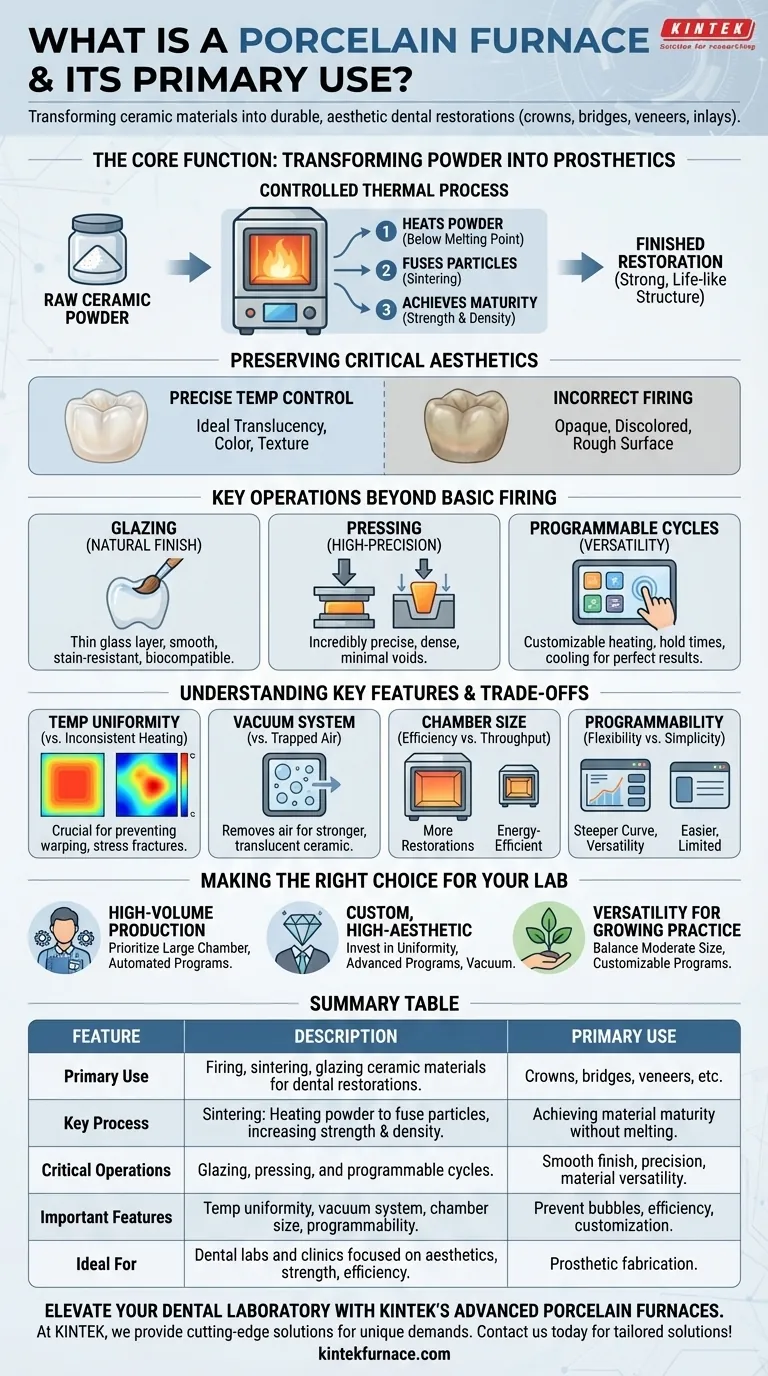

The Core Function: Transforming Powder into Prosthetics

The furnace's essential role is to manage the transformation of raw ceramic material into a finished, patient-ready product. This is accomplished through a highly controlled thermal process.

The Process of Sintering

Sintering is the cornerstone of ceramic fabrication. The furnace heats porcelain powder to a temperature just below its melting point.

This intense heat causes the individual ceramic particles to bond and fuse, drastically increasing the material's density and strength without liquefying it.

Achieving Material Maturity

The goal of firing is to bring the porcelain to "optimal maturity." This term refers to achieving the ideal final state of hardness, density, and stability.

Proper sintering ensures the restoration can withstand the significant forces of chewing over many years.

Preserving Critical Aesthetics

A furnace's value is not just in creating strength, but also in preserving beauty. Precise temperature control is vital for achieving the correct translucency, color accuracy, and surface texture.

Incorrect firing can result in a restoration that is opaque, discolored, or has a rough surface, compromising the natural look.

Key Operations Beyond Basic Firing

Modern porcelain furnaces are versatile machines capable of performing several distinct, crucial operations required for state-of-the-art restorations.

Glazing for a Natural Finish

Glazing is a final, lower-temperature firing cycle. A thin layer of glass is applied to the restoration, which melts to form a smooth, non-porous, and high-gloss surface.

This not only enhances the aesthetic appeal but also makes the restoration more stain-resistant and biocompatible with surrounding oral tissues.

Pressing for High-Precision Restorations

Some furnaces are equipped for "pressing" ceramics. In this process, a heated ceramic ingot is pressed into a mold under vacuum pressure.

This technique is used to create incredibly precise and dense restorations, such as full-contour crowns, with minimal internal voids.

Programmable Cycles for Material Versatility

Dental technology involves a vast array of ceramic materials, each with unique firing requirements.

Modern furnaces feature intelligent operating systems that allow technicians to program and save specific firing cycles—including heating rates, hold times, and cooling temperatures—to ensure perfect results for any given material.

Understanding the Trade-offs and Key Features

When evaluating a porcelain furnace, several technical features present important trade-offs that impact laboratory workflow and restoration quality.

Temperature Range and Uniformity

While a high maximum temperature is necessary, uniform heat distribution within the firing chamber is more critical.

Inconsistent heating can create hot or cold spots, leading to warping, stress fractures, or incomplete sintering in the final restoration. This is a common point of failure in lower-quality units.

The Role of the Vacuum System

Many advanced furnaces include a vacuum pump. Pulling a vacuum inside the chamber during firing removes trapped air from the porcelain.

This prevents bubbles and porosity, resulting in a significantly stronger and more translucent ceramic. For high-end aesthetic work, a vacuum is considered essential.

Chamber Size vs. Efficiency

A larger chamber can process more restorations simultaneously, boosting throughput for high-volume labs.

However, for a smaller clinic or a lab focused on single custom cases, a smaller, more energy-efficient chamber might be a more practical and cost-effective choice.

Programmability vs. Simplicity

Extensive programmability offers the flexibility to work with any ceramic on the market. This versatility comes at the cost of a steeper learning curve.

Simpler, pre-programmed units are easier to operate but may limit the lab's ability to adopt new or specialized materials in the future.

Making the Right Choice for Your Laboratory

Selecting a furnace requires aligning its capabilities with the specific goals of your practice or laboratory.

- If your primary focus is high-volume production: Prioritize a furnace with a large, reliable firing chamber and automated, easy-to-use programs to maximize throughput.

- If your primary focus is custom, high-aesthetic work: Invest in a furnace with exceptional temperature uniformity, advanced programmability, and a high-performance vacuum system.

- If your primary focus is versatility for a growing practice: Seek a model that balances a moderate chamber size with a wide range of customizable programs to handle diverse cases and new materials.

Ultimately, the right porcelain furnace is an investment in precision, ensuring every restoration meets the highest standards of function and aesthetics.

Summary Table:

| Feature | Description |

|---|---|

| Primary Use | Firing, sintering, and glazing ceramic materials for dental restorations (e.g., crowns, bridges, veneers). |

| Key Process | Sintering: Heating porcelain powder to fuse particles, increasing strength and density without melting. |

| Critical Operations | Glazing for a smooth finish, pressing for precision, and programmable cycles for material versatility. |

| Important Features | Temperature uniformity, vacuum system to prevent bubbles, chamber size, and programmability for customization. |

| Ideal For | Dental labs and clinics focused on aesthetics, strength, and efficiency in prosthetic fabrication. |

Elevate Your Dental Laboratory with KINTEK's Advanced Porcelain Furnaces

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide dental professionals with cutting-edge high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to meet the unique demands of dental prosthetics. With strong deep customization capabilities, we ensure our furnaces deliver precise temperature control, uniform heating, and reliable performance for sintering, glazing, and pressing ceramics—helping you create durable, aesthetically perfect restorations every time.

Whether you're a high-volume lab, a clinic focused on custom aesthetics, or a growing practice seeking versatility, KINTEK has the right furnace to enhance your workflow and outcomes. Contact us today to discuss how our tailored solutions can transform your dental prosthetic processes and drive success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations