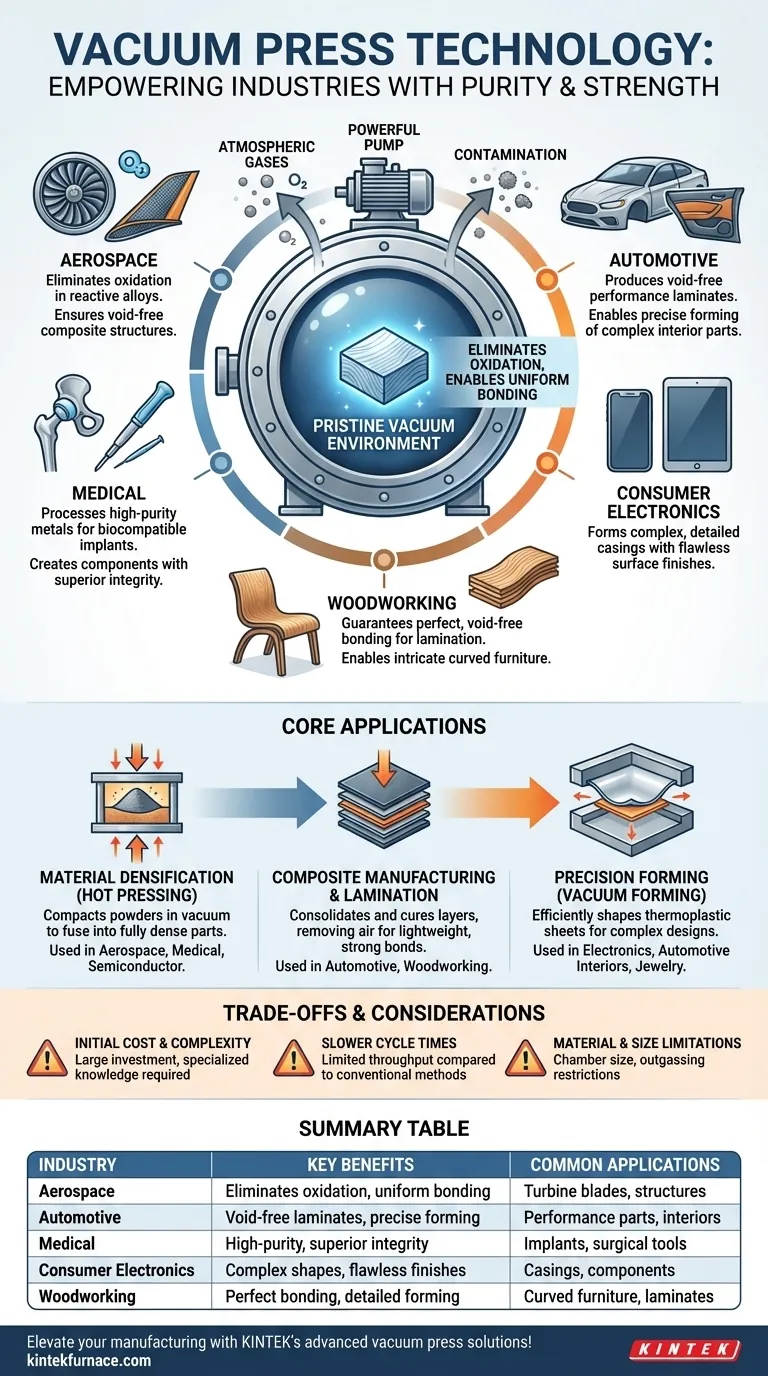

At its core, vacuum press technology has been instrumental in advancing industries where material purity, strength, and geometric complexity are paramount. Key sectors that have seen significant benefits include aerospace, automotive, medical, and consumer electronics, all of which rely on the technology to create components that would be difficult or impossible to produce using conventional methods. The process is also fundamental in specialized woodworking for lamination and forming.

The true value of a vacuum press is not just the pressure it applies, but the pristine environment it creates. By removing atmospheric gases, it eliminates contamination like oxidation, enabling the creation of materials and bonds with superior integrity and performance.

Why the Vacuum Environment is a Game-Changer

The fundamental advantage of any vacuum press system is the controlled, gas-free environment it establishes. This solves several critical manufacturing challenges that are unavoidable in open-air processes.

Eliminating Oxidation and Contamination

When metals and other reactive materials are heated in the presence of air, they oxidize. This creates a weak, brittle surface layer that compromises the material's structural integrity.

By removing oxygen and other atmospheric gases, a vacuum press ensures that materials—especially high-purity metals, reactive alloys, and advanced ceramics—are processed in a pristine state. This is non-negotiable for critical components like medical implants and aerospace turbine blades.

Enabling Uniform Pressure and Bonding

Air trapped between layers during lamination or composite manufacturing can create voids or bubbles. These imperfections become significant weak points in the final product.

A vacuum ensures that clamping pressure is applied perfectly and uniformly across a component's entire surface. This forces out any trapped volatiles and guarantees a void-free bond, which is essential for the reliability of composite aerospace structures and high-end laminated wood products.

Core Applications Driving Adoption

While the industries are diverse, the underlying applications of vacuum press technology fall into a few key categories. Understanding these functions reveals why it is such a versatile tool.

Material Densification and Sintering

This process, often called hot pressing, involves compacting powders (metal, ceramic, or composite) under heat and pressure inside a vacuum.

The vacuum prevents the powder particles from oxidizing as they are heated, allowing them to fuse together into a fully dense, solid part. This is how many high-performance components for the aerospace, medical, and semiconductor industries are made.

Composite Manufacturing and Lamination

Vacuum presses are used to consolidate and cure layers of composite materials, such as carbon fiber pre-preg, or to laminate veneers onto a wood substrate.

The system pulls the flexible layers tightly against the mold, squeezing out excess resin and eliminating air pockets. This results in a lightweight, strong, and perfectly bonded part, a technique used heavily in automotive (for performance parts) and woodworking (for curved furniture).

Precision Forming and Shaping

For shaping sheets of material, a process known as vacuum forming is used. A heated sheet of thermoplastic or a similar pliable material is drawn onto a mold using vacuum suction.

This method is exceptionally efficient for creating complex, detailed shapes with high-quality surface finishes. It is a cornerstone of manufacturing for consumer electronics casings, automotive interior panels, and even jewelry molds.

Understanding the Trade-offs

While powerful, vacuum press technology is not a universal solution. The decision to implement it involves clear trade-offs that must be considered.

Initial Cost and Complexity

Vacuum systems, especially high-temperature vacuum hot presses, represent a significant capital investment. The machinery is complex, requiring specialized knowledge for operation and maintenance.

Slower Cycle Times

Compared to conventional methods like stamping or injection molding, vacuum pressing processes can be significantly slower. The time required to pump down the chamber, run the heating and cooling cycle, and vent the system can limit throughput for high-volume production.

Material and Size Limitations

The size of the component is limited by the physical dimensions of the vacuum chamber. Furthermore, while the technology is versatile, not all materials are suitable for vacuum processing, particularly those that may outgas excessively and contaminate the system.

Making the Right Choice for Your Goal

Your specific objective will determine if vacuum press technology is the appropriate solution for your application.

- If your primary focus is maximum material purity and strength: This technology is essential for creating mission-critical parts from reactive or advanced materials, as seen in aerospace and medical implants.

- If your primary focus is complex shapes with a flawless finish: Vacuum forming is an ideal and cost-effective method for producing detailed plastic parts for consumer electronics and automotive interiors.

- If your primary focus is creating void-free laminates or composites: A vacuum press is the definitive tool for ensuring perfect bonding and structural integrity in everything from high-end furniture to performance race car bodies.

Ultimately, vacuum press technology empowers engineers and designers to build products that are stronger, purer, and more intricate than ever before.

Summary Table:

| Industry | Key Benefits | Common Applications |

|---|---|---|

| Aerospace | Eliminates oxidation, enables uniform bonding | Turbine blades, composite structures |

| Automotive | Void-free laminates, precise forming | Performance parts, interior panels |

| Medical | High-purity materials, superior integrity | Implants, surgical tools |

| Consumer Electronics | Complex shapes, flawless finishes | Casings, components |

| Woodworking | Perfect bonding, detailed forming | Curved furniture, laminates |

Elevate your manufacturing with KINTEK's advanced vacuum press solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique needs in aerospace, automotive, medical, and electronics. Contact us today to discuss how we can enhance your material purity, strength, and geometric complexity!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision