When choosing a porcelain furnace, the critical factors are its reliability, temperature accuracy, programmability for specific materials, and the size of its firing chamber. These elements directly determine the quality of your restorations, the efficiency of your workflow, and the long-term profitability of your lab.

The best porcelain furnace is not necessarily the one with the most features, but the one that most consistently and reliably meets the specific material demands of your lab, minimizing costly remakes and maximizing productivity.

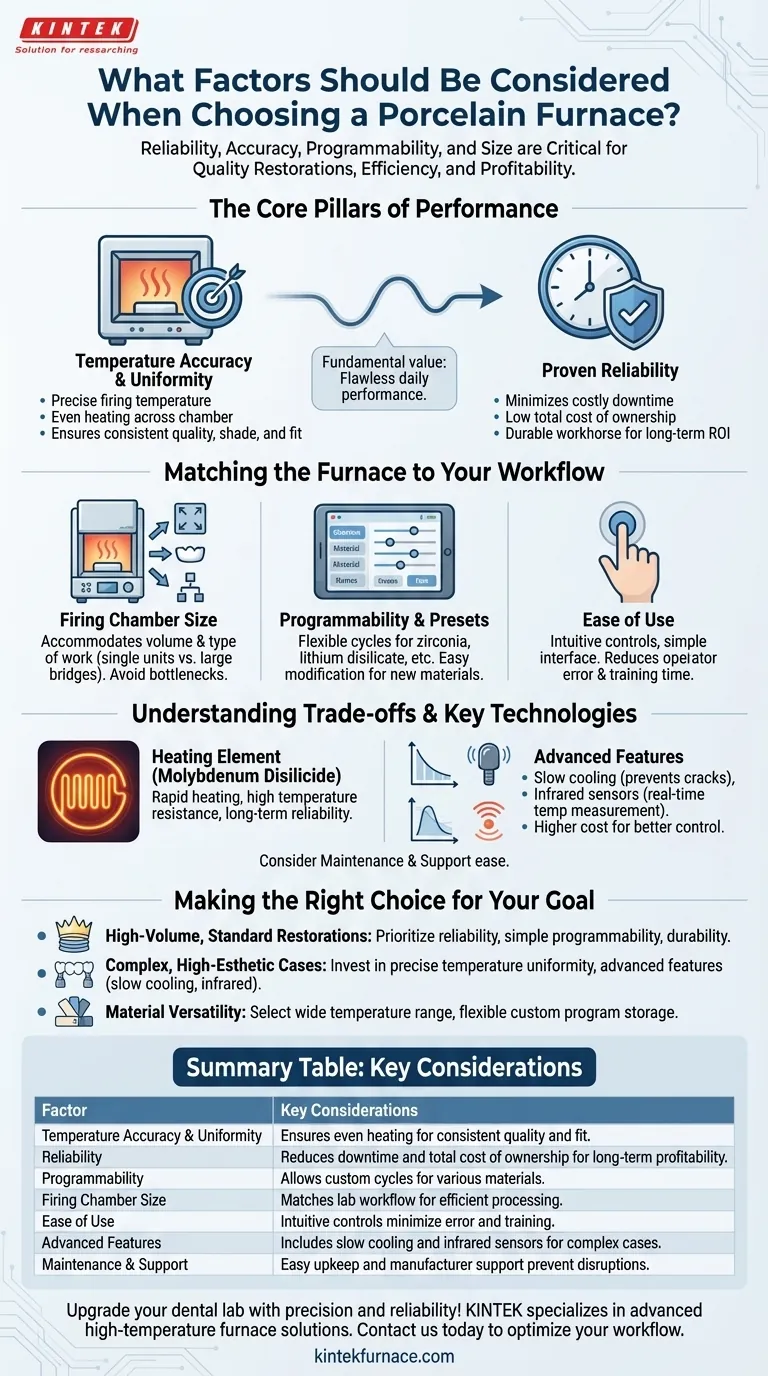

The Core Pillars of Performance

The fundamental value of a furnace lies in its ability to perform its core function flawlessly, day after day. Everything else is secondary to these two pillars.

Temperature Accuracy and Uniformity

A furnace’s primary job is to execute a firing cycle at a precise temperature. Temperature uniformity across the entire firing chamber ensures that every part of a restoration, from a thin margin to a thick pontic, is heated evenly.

Inconsistent heating leads to internal stresses, poor fit, incorrect shades, and a lack of vitality in the final ceramic. High temperature control accuracy is non-negotiable for achieving predictable, high-quality clinical outcomes.

Proven Reliability

Downtime is more than an inconvenience; it is lost revenue and a damaged reputation. A furnace that breaks down frequently or requires constant recalibration becomes a liability.

Look for models with a proven track record of reliability over time. The cost of a furnace is not just its purchase price but its total cost of ownership, and a reliable workhorse often provides a far better return on investment.

Matching the Furnace to Your Workflow

Beyond core performance, the furnace must integrate seamlessly into your lab's daily operations. Its design should enhance efficiency, not hinder it.

Firing Chamber Size and Design

The size of the firing chamber dictates the volume and type of work you can process. A small chamber may be efficient for a lab focused on single-unit crowns, but it will become a bottleneck if you frequently fabricate large, multi-unit bridges.

Ensure the chamber can accommodate the largest restorations your lab produces without compromising heat circulation.

Programmability and Presets

Modern ceramics have highly specific firing parameters. The furnace must have flexible programmability to create and save custom cycles for different materials like zirconia, lithium disilicate, and layered porcelains.

Pre-loaded programs are a convenient starting point, but the ability to easily modify them is essential for fine-tuning results and adapting to new materials as they enter the market.

Ease of Use

A complex user interface increases the risk of operator error and extends training time for new technicians. The furnace should have a straightforward control panel and an intuitive menu system.

The goal is to enable any trained technician to operate the furnace confidently, ensuring consistent results regardless of who is running the cycle.

Understanding the Trade-offs and Key Technologies

Not all features are necessary for every lab. Understanding the underlying technology and its practical impact helps you invest wisely.

The Role of the Heating Element

Most modern furnaces use heating elements made of molybdenum disilicide. This material is favored for its ability to heat up rapidly and withstand extremely high temperatures without degrading, contributing to both speed and long-term reliability.

Standard vs. Advanced Firing Features

Many furnaces offer specialized features. Slow cooling programs are critical for preventing cracks and fractures in large zirconia frameworks or restorations with mismatched coefficients of thermal expansion.

Advanced infrared sensors offer real-time temperature measurement of the restoration itself, not just the air in the chamber. This provides a more accurate firing cycle but comes at a higher initial cost.

Maintenance and Manufacturer Support

Every furnace requires routine maintenance, such as calibration and cleaning. Consider how easy it is to perform these tasks and the availability of technical support and replacement parts from the manufacturer.

Strong post-sale support can be the difference between a minor issue and a multi-day shutdown.

Making the Right Choice for Your Goal

Your final decision should be guided by a clear understanding of your lab’s primary function and business objectives.

- If your primary focus is high-volume, standard restorations: Prioritize a furnace with proven reliability, simple programmability, and a reputation as a durable workhorse.

- If your primary focus is complex, high-esthetic cases: Invest in a furnace with precise temperature uniformity and advanced features like programmable slow cooling and infrared technology.

- If your primary focus is material versatility: Select a furnace with a wide temperature range and the flexibility to easily create and store dozens of custom firing programs.

Ultimately, the right furnace is an investment in predictable, high-quality outcomes for your lab and your patients.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Accuracy & Uniformity | Ensures even heating for consistent restoration quality and fit. |

| Reliability | Reduces downtime and total cost of ownership for long-term profitability. |

| Programmability | Allows custom cycles for materials like zirconia and lithium disilicate. |

| Firing Chamber Size | Matches lab workflow for single units or large bridges without bottlenecks. |

| Ease of Use | Intuitive controls minimize operator error and training time. |

| Advanced Features | Includes slow cooling and infrared sensors for complex cases. |

| Maintenance & Support | Easy upkeep and manufacturer support prevent operational disruptions. |

Upgrade your dental lab with precision and reliability! KINTEK specializes in advanced high-temperature furnace solutions tailored for laboratories like yours. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by deep customization capabilities to meet your unique experimental needs. Whether you're handling high-volume restorations or complex aesthetic cases, we ensure consistent performance and enhanced productivity. Contact us today to discuss how our furnaces can optimize your workflow and deliver superior results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures