At its core, the duration of the zirconia sintering process is not a fixed time but a variable outcome determined by four key factors: the specific zirconia material, the size of the restoration, the capabilities of your furnace, and the final aesthetic and structural properties you need to achieve. A standard cycle can take several hours, while specialized "speed" cycles can be completed in as little as 65 to 90 minutes.

The central challenge in zirconia sintering is managing the trade-off between speed and quality. While fast cycles offer significant workflow advantages, they must be used correctly to avoid compromising the strength, esthetics, and long-term stability of the final restoration.

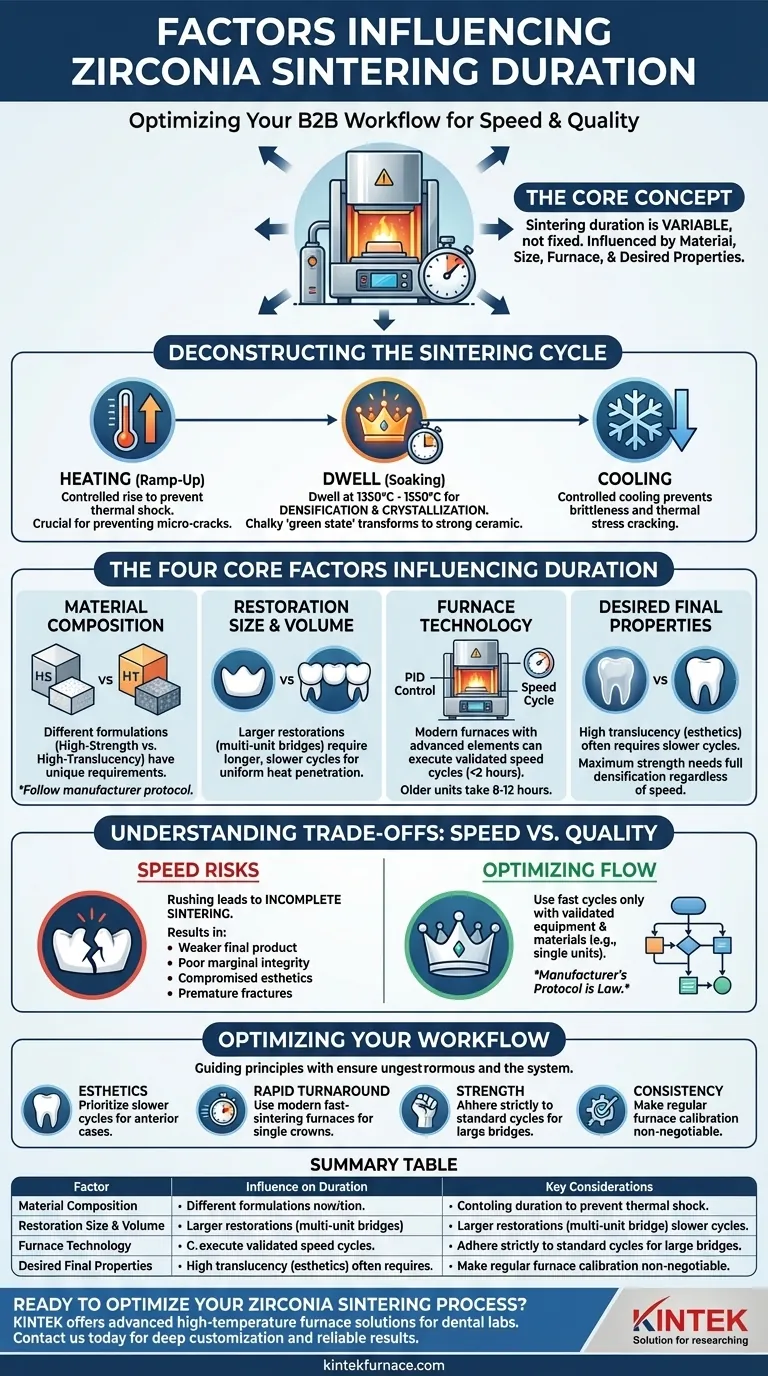

Deconstructing the Sintering Cycle

To understand duration, you must first understand the three distinct phases of any sintering program. The total time is the sum of these phases, each of which is critical to the final outcome.

The Heating Phase (Ramp-Up)

This is the initial period where the furnace temperature gradually increases to the target. A controlled, steady ramp-up is essential to prevent thermal shock, which can introduce micro-cracks into the material before it's even fully sintered.

The Dwell Phase (Soaking)

Once the target temperature is reached—typically between 1350°C and 1550°C—the furnace "dwells" or "soaks" at that temperature for a set period. This is the most critical phase, where the material undergoes densification and crystallization, transforming the chalky "green state" zirconia into a hard, strong ceramic.

The Cooling Phase

Equally as important as heating, the controlled cooling phase allows the restoration to return to room temperature without thermal stress. Cooling too quickly can make the material brittle or cause it to crack, ruining the restoration.

The Four Core Factors Influencing Duration

The length of each phase—and thus the total cycle time—is dictated by the following variables.

1. Zirconia Material Composition

Different zirconia formulations have unique sintering requirements. High-strength (HS) zirconia often requires different parameters than high-translucency (HT) material intended for esthetic anterior cases. Always begin with the protocol recommended by the material's manufacturer.

2. Restoration Size and Volume

This is a matter of thermal physics. A small, single-unit crown can be heated and cooled relatively quickly and uniformly. A large, multi-unit bridge requires a much longer and slower cycle to ensure heat penetrates the entire structure evenly, preventing internal stress and ensuring complete densification.

3. Furnace Technology and Capabilities

Modern sintering furnaces are a primary driver of reduced cycle times. Older equipment may require 8-12 hours for a standard cycle. Newer furnaces featuring high-purity silicon molybdenum heating elements and precise PID temperature control can execute validated "speed" cycles in under two hours. These advanced systems can ramp up and cool down much faster without damaging the restoration.

4. Desired Final Properties

The final goal dictates the process. If achieving the absolute highest translucency is the priority for an anterior crown, a longer, slower cycle is often preferred as it gives the material's crystal structure more time to form optimally. If maximum strength is the goal for a posterior bridge, the cycle must be long enough to guarantee full densification, regardless of speed.

Understanding the Trade-offs: Speed vs. Quality

The appeal of a 90-minute cycle is undeniable, but it comes with critical considerations. Using speed cycles incorrectly is one of the most common sources of restoration failure.

The Risk of Rushing

An improperly executed fast cycle can lead to incomplete sintering. This results in a weaker final product with lower flexural strength, poor marginal integrity, and compromised esthetics (lower translucency). It is the primary cause of premature fractures.

When to Use Fast Cycles

Speed sintering is not a universal solution. It should only be used with furnaces and zirconia materials that have been specifically designed and validated for this purpose. It is most reliable for single-unit crowns and smaller restorations.

The Manufacturer's Protocol is Law

The instructions provided by the zirconia manufacturer are not mere suggestions; they are the result of extensive testing to achieve predictable results. Deviating from these protocols to save time introduces significant risk and may void the material's warranty.

Optimizing Your Sintering Workflow

Choosing the right cycle is about aligning your equipment, materials, and clinical goals. Use these principles as your guide.

- If your primary focus is maximum esthetics for anterior cases: Prioritize slower, conventional sintering cycles that are proven to enhance the translucency and vitality of the ceramic.

- If your primary focus is rapid turnaround for single crowns: Invest in a modern, fast-sintering furnace and use only zirconia materials that are explicitly validated by their manufacturer for such cycles.

- If your primary focus is strength for large-span bridges: Adhere strictly to the manufacturer's recommended standard (and typically longer) cycle to ensure complete, uniform densification and structural integrity.

- If your primary focus is operational consistency and quality control: Make regular furnace calibration a non-negotiable part of your workflow and ensure every technician understands that the material's instructions dictate the process.

Mastering these variables gives you precise control over the balance of efficiency and quality, ensuring every restoration you produce is both beautiful and built to last.

Summary Table:

| Factor | Influence on Duration | Key Considerations |

|---|---|---|

| Zirconia Material Composition | Varies based on type (e.g., HS vs. HT) | Follow manufacturer protocols for optimal results |

| Restoration Size and Volume | Larger restorations require longer cycles | Ensures uniform heating and prevents stress |

| Furnace Technology | Advanced furnaces reduce time with fast cycles | Use high-precision elements for speed sintering |

| Desired Final Properties | Longer cycles for high translucency or strength | Balance speed with quality to avoid failures |

Ready to optimize your zirconia sintering process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental labs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Enhance your workflow with reliable, efficient sintering—contact us today to discuss how we can support your lab's success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity