The defining characteristic of a vacuum furnace is its ability to conduct heat treatment processes within a controlled, sub-atmospheric environment. Unlike conventional furnaces that operate in the open air or with controlled gas atmospheres, a vacuum furnace removes the reactive elements—primarily oxygen—that cause oxidation and contamination. This fundamental difference allows for a level of material purity and process control that is simply unattainable with other methods.

A vacuum furnace is not just a tool for heating; it is a precision instrument for material transformation. By eliminating atmospheric variables, it enables a level of purity, uniformity, and performance enhancement that is impossible to achieve in a conventional furnace.

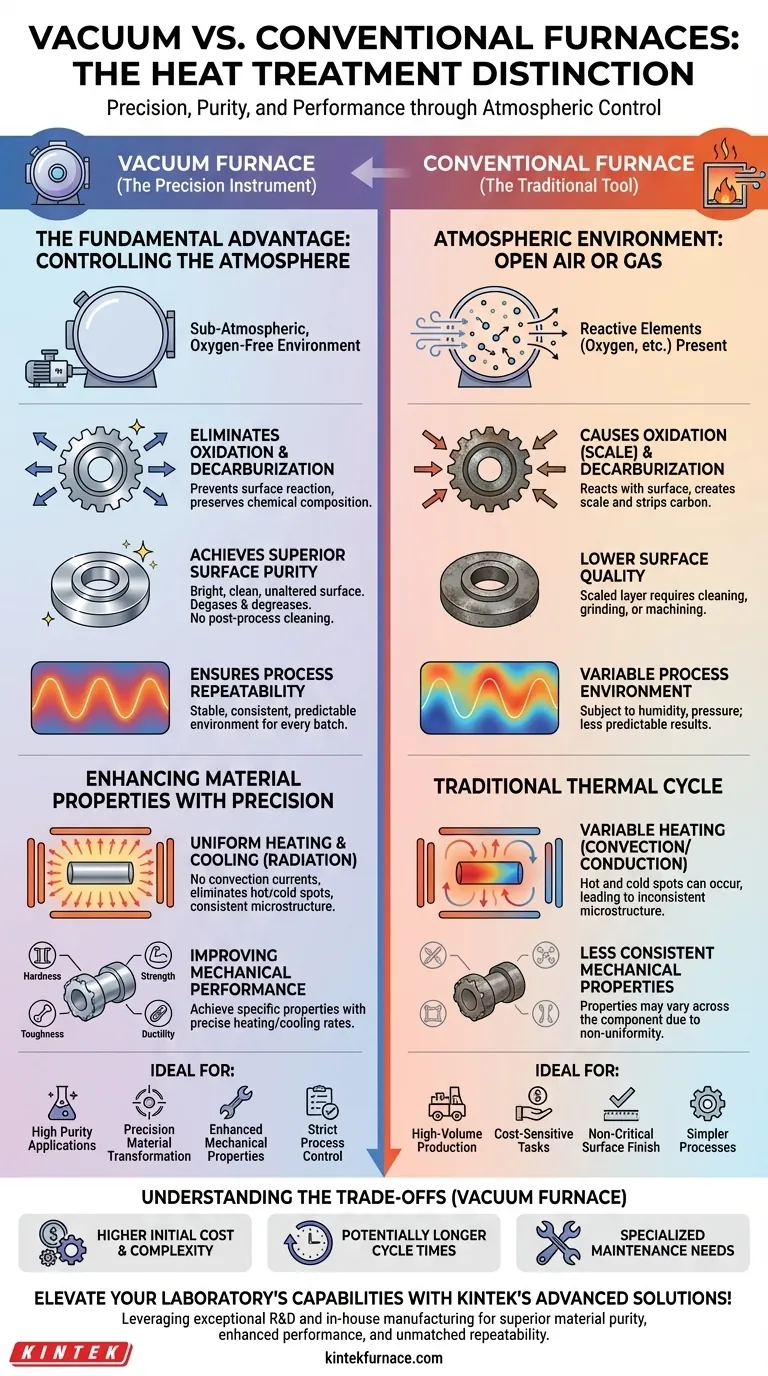

The Fundamental Advantage: Controlling the Atmosphere

The primary distinction of a vacuum furnace is the vacuum itself. Removing the air from the heating chamber fundamentally changes the heat treatment process and its outcomes.

Eliminating Oxidation and Decarburization

In a traditional furnace, high temperatures cause oxygen in the air to react with the metal's surface, creating scale and discoloration. A vacuum environment is virtually free of oxygen, preventing this oxidative reaction entirely.

Similarly, the atmosphere can react with steel at high temperatures and strip carbon from its surface, a negative effect known as decarburization. By removing the atmosphere, a vacuum furnace preserves the material's original chemical composition.

Achieving Superior Surface Purity

The result of preventing oxidation is a workpiece with a bright, clean, and unaltered surface. There is no need for post-process cleaning, grinding, or machining to remove a scaled layer.

Furthermore, the vacuum actively helps to degas and degrease the material, pulling impurities and volatile substances like phosphorus from the workpiece surface for an even purer final product.

Ensuring Process Repeatability

An atmospheric environment is subject to variables like humidity and barometric pressure. A vacuum chamber creates a stable, consistent, and highly repeatable processing environment.

This ensures that every batch receives the exact same treatment, leading to predictable and uniform results every time.

Enhancing Material Properties with Precision

Controlling the atmosphere is only part of the equation. Vacuum furnaces also provide unparalleled control over the thermal cycle itself.

Uniform Heating and Cooling

With no air to create convection currents, heat transfer in a vacuum is dominated by radiation. This allows for extremely uniform heating, eliminating the hot and cold spots that can occur in conventional furnaces.

This thermal uniformity leads to a more consistent microstructure throughout the material, which is critical for high-performance applications.

Improving Mechanical Performance

The precise control over heating, soaking, and cooling rates allows engineers to achieve specific, targeted material properties.

This results in measurable improvements to hardness, strength, toughness, and ductility. The uniform structure created by vacuum treatment ensures these properties are consistent across the entire component.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the universal solution for all heat treatment needs. Understanding their specific requirements is key.

Higher Initial Cost and Complexity

Vacuum furnaces are sophisticated systems involving vacuum pumps, sealed chambers, and advanced control instrumentation. This complexity results in a higher capital investment compared to simpler atmospheric furnaces.

Potentially Longer Cycle Times

The process of evacuating the chamber to the required vacuum level adds time to the beginning of each cycle. Depending on the process, radiative heating can also be slower than forced convection, potentially extending the overall process time.

Specialized Maintenance Needs

The integrity of the vacuum is paramount. Seals, pumps, and sensors require a rigorous and specialized maintenance schedule to prevent leaks and ensure the system operates at peak performance.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace should be driven by the desired outcome for your material and final component.

- If your primary focus is achieving the highest material purity and a pristine surface finish: A vacuum furnace is the unequivocal choice to prevent any oxidation or contamination.

- If your primary focus is maximizing mechanical performance and process repeatability: The precise thermal control of a vacuum furnace delivers the uniformity required for superior strength and consistency.

- If your primary focus is high-volume, low-cost processing where surface oxidation is acceptable or can be removed later: A conventional atmospheric furnace may be a more cost-effective solution.

Ultimately, selecting a vacuum furnace is an investment in final component quality and process control.

Summary Table:

| Feature | Vacuum Furnace | Other Furnaces |

|---|---|---|

| Atmosphere | Controlled vacuum, no oxygen | Air or gas atmospheres |

| Oxidation Prevention | Yes, eliminates oxidation | No, oxidation occurs |

| Surface Finish | Bright and clean, no post-cleaning | Scaled, requires cleaning |

| Process Repeatability | High, due to stable environment | Lower, affected by variables |

| Heating Uniformity | High, via radiation | Variable, with hot/cold spots |

| Cost | Higher initial investment | Lower initial cost |

| Ideal For | High purity, precision applications | High-volume, cost-sensitive tasks |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, helping you achieve superior material purity, enhanced mechanical performance, and unmatched process repeatability. Don't settle for less—contact us today to discuss how our tailored solutions can transform your heat treatment processes and drive your research forward!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today