The fundamental difference between direct and indirect rotary kilns lies entirely in the method of heat application. In a direct-fired kiln, the flame and hot combustion gases are inside the kiln, making direct contact with the material being processed. Conversely, an indirect-fired kiln is heated from the outside, with heat transferring through the metal shell to the material, which never touches the combustion source.

The choice between a direct and indirect kiln is dictated by your material's chemistry. Direct kilns offer superior thermal efficiency for robust materials, while indirect kilns provide the process purity and control required for sensitive materials or specialized atmospheres.

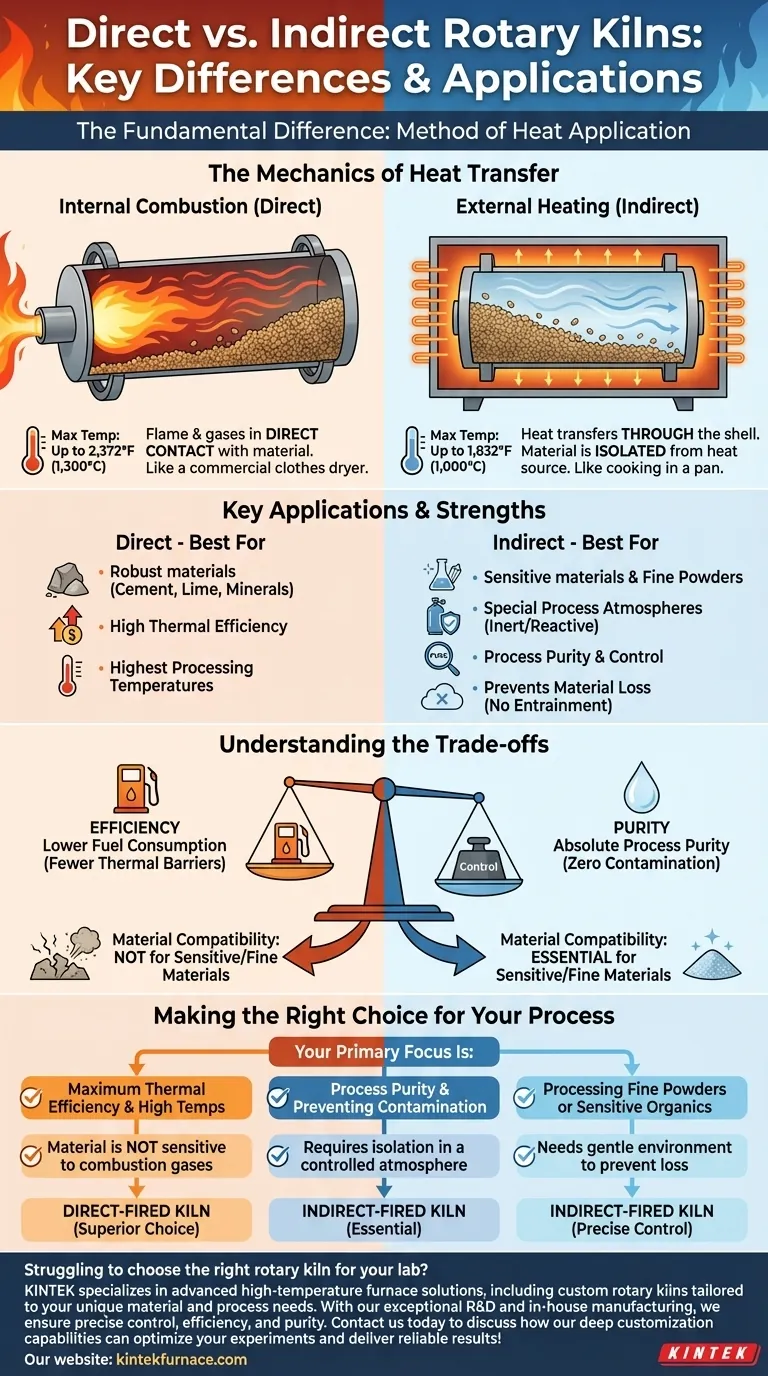

The Mechanics of Heat Transfer

The design of a rotary kiln directly determines how thermal energy reaches the process material. This single difference in heat transfer mechanics creates two distinct classes of equipment with different strengths.

Direct-Fired Kilns: Internal Combustion

In a direct-fired system, a burner injects fuel and air into the rotating drum, creating a flame and hot gases that flow through the kiln, usually in contact with the material.

This method promotes very effective heat transfer through convection and radiation directly from the gas stream to the material bed. Think of it like a commercial clothes dryer where hot air tumbles directly with the clothes.

These kilns are capable of achieving very high process temperatures, often reaching up to 2,372°F (1,300°C).

Indirect-Fired Kilns: External Heating

In an indirect-fired system, the rotating kiln drum is enclosed within a stationary furnace or surrounded by external heating elements. The heat source never enters the drum.

Heat must first transfer to the outside of the rotating shell and then conduct through the shell wall to heat the material inside. This is analogous to cooking food in a pan on a stove—the flame heats the pan, which in turn cooks the food.

This design limits the maximum temperature, typically operating up to 1,832°F (1,000°C), as the shell material itself becomes a limiting factor.

Key Applications and Operating Principles

Your specific process goal—whether it's raw calcination or delicate chemical modification—will point you toward one design over the other.

When to Use a Direct-Fired Kiln

Direct-fired kilns are the industry workhorse for high-volume, high-temperature applications where the material is chemically robust.

They are ideal for processing materials that are not negatively affected by contact with combustion byproducts like CO₂, H₂O, and excess oxygen. Common applications include the production of cement, lime, and the calcination of minerals.

The primary driver for choosing a direct kiln is its high thermal efficiency and ability to achieve the highest possible processing temperatures.

When to Use an Indirect-Fired Kiln

Indirect-fired kilns are chosen when process control and material purity are paramount. They solve problems that direct kilns cannot.

Their most critical application is when a special process atmosphere is required. Because the material is isolated, the kiln can be filled with an inert gas (like nitrogen) to prevent oxidation or a reactive gas for specific chemical processes.

They are also essential for processing very fine materials. In a direct kiln, the high-velocity gas flow can blow fine powders out of the drum (a phenomenon called entrainment), leading to material loss. The quiescent atmosphere in an indirect kiln prevents this.

Understanding the Trade-offs

Selecting the right kiln requires an objective assessment of the trade-offs between thermal efficiency and process control.

Efficiency vs. Purity

The core trade-off is simple: efficiency for purity. Direct kilns transfer heat more efficiently because there are fewer thermal barriers, resulting in lower fuel consumption for a given temperature.

Indirect kilns sacrifice some of this efficiency to guarantee absolute process purity, ensuring the material is never contaminated by flue gas.

Temperature Range

Direct kilns have a clear advantage in achieving the highest possible temperatures, making them the only choice for certain metallurgical and mineralogical transformations. The temperature ceiling of an indirect kiln is limited by the heat tolerance and thermal conductivity of its metal shell.

Material Compatibility

This is the most critical deciding factor. If your material is sensitive and can be damaged or altered by the chemical environment of a combustion gas stream, an indirect kiln is not just an option—it is a necessity.

If your material is a fine powder, the potential for material loss through entrainment in a direct kiln often makes an indirect kiln the only practical choice.

Making the Right Choice for Your Process

Your decision should be guided by a clear understanding of your material's properties and your ultimate process objective.

- If your primary focus is maximum thermal efficiency and high temperatures: A direct-fired kiln is the superior choice, provided your material is not sensitive to combustion gases.

- If your primary focus is process purity and preventing contamination: An indirect-fired kiln is essential, as it completely isolates the material in a controlled atmosphere.

- If your primary focus is processing fine powders or temperature-sensitive organics: An indirect-fired kiln provides the gentle environment needed to prevent material loss and ensure precise thermal control.

By prioritizing your material's needs, you can confidently select the kiln technology that will deliver the most reliable and effective results.

Summary Table:

| Feature | Direct-Fired Kiln | Indirect-Fired Kiln |

|---|---|---|

| Heat Transfer | Direct contact with combustion gases | External heating through shell |

| Max Temperature | Up to 2,372°F (1,300°C) | Up to 1,832°F (1,000°C) |

| Ideal Applications | Cement, lime, mineral calcination | Sensitive materials, fine powders, controlled atmospheres |

| Key Advantage | High thermal efficiency | Process purity and control |

Struggling to choose the right rotary kiln for your lab? KINTEK specializes in advanced high-temperature furnace solutions, including custom rotary kilns tailored to your unique material and process needs. With our exceptional R&D and in-house manufacturing, we ensure precise control, efficiency, and purity for applications like calcination or sensitive material handling. Contact us today to discuss how our deep customization capabilities can optimize your experiments and deliver reliable results!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What types of physical and chemical transformations occur in a rotary kiln? Master Material Processing for Superior Results

- What data is necessary to design a rotary kiln? Essential Factors for Efficient Thermal Processing

- What role does gas flow and combustion play in a rotary kiln? Optimize Heat Transfer for Efficiency and Quality

- What are the primary applications of an electric rotary kiln? Achieve High-Purity Material Processing with Precision