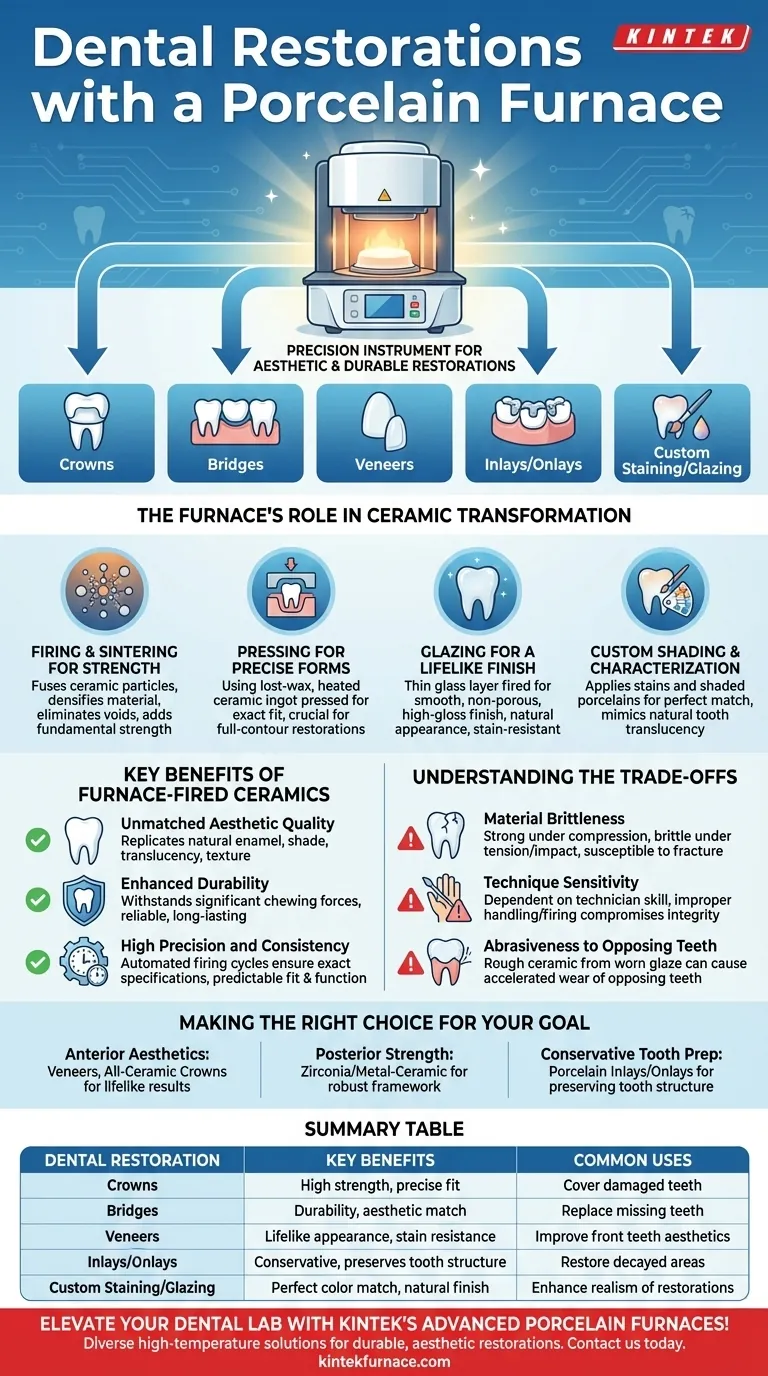

At its core, a dental porcelain furnace is used to create a wide range of highly aesthetic and durable restorations. The most common applications include the fabrication of crowns, bridges, veneers, inlays, and onlays, as well as the custom staining and glazing required to match them perfectly to a patient's natural teeth.

A porcelain furnace is not merely an oven; it is a precision instrument that transforms raw ceramic materials into strong, lifelike dental prosthetics. Its function is to control heat with extreme accuracy to achieve the strength, fit, and aesthetic qualities that modern restorative dentistry demands.

The Furnace's Role in Ceramic Transformation

A porcelain furnace performs several distinct thermal processes, each critical to the final quality of the restoration. Understanding these functions reveals why the furnace is indispensable in a dental laboratory.

Firing and Sintering for Strength

The primary function is sintering, a process where high heat is applied to fuse ceramic particles together without melting them. This densifies the material, eliminates voids, and provides the restoration with its fundamental strength and durability.

Pressing for Precise Forms

Many furnaces are also pressing furnaces. Using techniques like the lost-wax method, a heated ceramic ingot is pressed into a mold to create an incredibly precise form. This is essential for full-contour restorations like crowns and bridges that require an exact fit.

Glazing for a Lifelike Finish

The final heating cycle is glazing. A thin layer of glass is fired onto the restoration's surface, creating a smooth, non-porous, and high-gloss finish. This glaze not only gives the restoration a natural, vital appearance but also makes it stain-resistant and kind to opposing teeth.

Custom Shading and Characterization

To achieve a perfect match, technicians apply stains and shaded porcelains to the restoration's surface. The furnace is then used to fire these layers, permanently bonding the color and creating the subtle translucency and characterization that mimic a natural tooth.

The Key Benefits of Furnace-Fired Ceramics

The precise control offered by a modern porcelain furnace translates directly into tangible benefits for both the clinician and the patient.

Unmatched Aesthetic Quality

Furnace-fired ceramics are the gold standard for aesthetics. They allow technicians to replicate the complex shade, translucency, and surface texture of natural enamel, making restorations virtually undetectable.

Enhanced Durability

The sintering process ensures that restorations like crowns and bridges can withstand the significant chewing forces exerted in the mouth. This leads to strong, reliable, and long-lasting results.

High Precision and Consistency

Automated, pre-programmed firing cycles remove guesswork and ensure that every restoration meets exact specifications. This consistency is critical for achieving a predictable fit and function.

Understanding the Trade-offs

While furnace-fired ceramics offer immense benefits, it is crucial to understand their limitations to ensure successful clinical outcomes.

Material Brittleness

Porcelain is a glass-ceramic, making it very strong under compression but potentially brittle under tension or sharp impact. This can make it susceptible to fracture if not designed with adequate thickness or if the patient has heavy parafunctional habits like grinding.

Technique Sensitivity

The final quality of the restoration is highly dependent on the skill of the dental technician. Improper material handling, inadequate support during firing, or incorrect heating programs can all compromise the integrity and fit of the final prosthetic.

Abrasiveness to Opposing Teeth

If the glaze on a porcelain restoration wears away or is improperly polished after adjustment, the rougher ceramic underneath can cause accelerated wear of the opposing natural teeth. Proper finishing and regular monitoring are essential.

Making the Right Choice for Your Goal

The versatility of furnace-fired ceramics allows for solutions tailored to specific clinical needs.

- If your primary focus is anterior aesthetics: Veneers and all-ceramic crowns allow for the most lifelike results, perfectly matching shade and translucency.

- If your primary focus is posterior strength: Zirconia-based or metal-ceramic crowns and bridges provide the robust framework needed to withstand heavy chewing forces.

- If your primary focus is conservative tooth preparation: Porcelain inlays and onlays are the ideal choice for restoring smaller areas of decay while preserving healthy tooth structure.

Ultimately, the porcelain furnace is the critical link that turns a technician's skill and advanced materials into a functional and beautiful dental restoration.

Summary Table:

| Dental Restoration | Key Benefits | Common Uses |

|---|---|---|

| Crowns | High strength, precise fit | Cover damaged teeth |

| Bridges | Durability, aesthetic match | Replace missing teeth |

| Veneers | Lifelike appearance, stain resistance | Improve front teeth aesthetics |

| Inlays/Onlays | Conservative, preserves tooth structure | Restore decayed areas |

| Custom Staining/Glazing | Perfect color match, natural finish | Enhance realism of restorations |

Elevate your dental lab's capabilities with KINTEK's advanced porcelain furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs for creating durable, aesthetic dental restorations. Contact us today to discuss how our tailored solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations