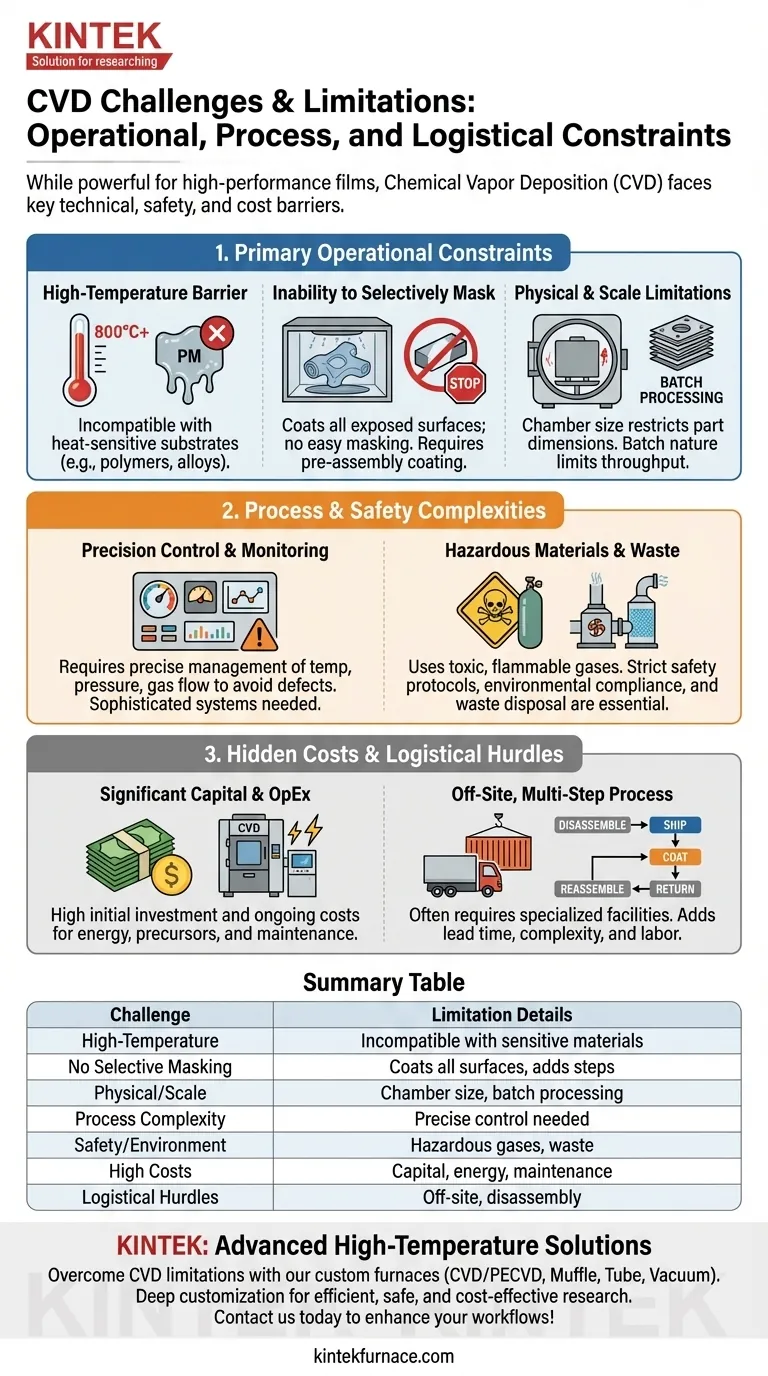

While a powerful technique for creating high-performance films, Chemical Vapor Deposition (CVD) is constrained by several key factors. Its high-temperature requirements limit its use to heat-resistant materials, the process coats all exposed surfaces without the ability to mask specific areas, and physical chamber dimensions restrict the size and quantity of parts that can be processed at once. These factors, combined with process complexity and safety concerns, define its practical limitations.

The challenges of Chemical Vapor Deposition are not just technical hurdles; they are fundamental operational trade-offs involving material compatibility, process scale, safety, and cost. Understanding these limitations is critical to determining if CVD is a viable and efficient solution for your specific application.

Unpacking the Primary Operational Constraints

To properly evaluate CVD, you must first understand its inherent physical and thermal boundaries. These constraints often dictate whether the process is suitable for a given material or production scale from the outset.

The High-Temperature Barrier

Many CVD processes require elevated temperatures, often several hundred degrees Celsius, to initiate the chemical reactions that form the desired film.

This high heat is incompatible with temperature-sensitive substrates like polymers or certain metal alloys, which could melt, warp, or lose their structural integrity. This fundamentally limits the range of materials that can be successfully coated.

Inability to Selectively Mask

CVD is an "all-or-nothing" process that coats every surface exposed to the precursor gases inside the reaction chamber.

There is no simple or standard way to mask off specific areas to prevent coating. This means components must often be coated individually before assembly, adding complexity to the manufacturing workflow.

Physical and Scale Limitations

The deposition occurs inside a sealed vacuum chamber, and the dimensions of this chamber dictate the maximum size of any part that can be coated.

Furthermore, chamber capacity limits the number of parts that can be processed in a single run. This reliance on batch processing can increase lead times and reduce throughput, especially for high-volume manufacturing.

Understanding the Process and Safety Complexities

Beyond its physical limitations, CVD is a technically demanding process that requires significant investment in control systems, safety infrastructure, and expert oversight.

The Need for Precision Control

The quality of a CVD film depends on the precise management of multiple variables, including temperature, pressure, gas concentrations, and flow rates.

Even minor deviations from the optimal parameters can result in film defects, poor adhesion, or inconsistent thickness. This necessitates sophisticated control systems and rigorous process monitoring.

Handling Hazardous Materials

The precursor chemicals used in CVD are often toxic, flammable, or corrosive gases.

Handling these materials requires specialized equipment, failsafe systems, and highly trained personnel to mitigate risks. Stringent safety protocols are non-negotiable.

Environmental and Waste Management

The CVD process can generate hazardous byproducts, including unreacted precursor gases and other volatile compounds.

Effective exhaust ventilation, gas scrubbing systems, and proper waste disposal are essential for environmental compliance and workplace safety, adding to the operational overhead.

The Hidden Costs and Logistical Hurdles

The total cost of using CVD extends beyond the equipment itself. The logistical and financial realities can make it a challenging choice for many projects.

Significant Capital and Operational Costs

The initial investment for CVD equipment—including the reaction chamber, vacuum pumps, and gas handling systems—is substantial.

Ongoing operational costs are also high due to energy consumption for heating, the price of high-purity precursor gases, and the maintenance of complex safety and waste management systems.

An Off-Site, Multi-Step Process

CVD is not a process that can typically be performed on a standard factory floor. It requires a dedicated, specialized facility.

This off-site nature introduces logistical challenges, requiring parts to be shipped for coating. Furthermore, complex products must often be fully disassembled into individual components for coating and then reassembled, adding significant labor and time to the overall production cycle.

Is CVD the Right Choice for Your Application?

Choosing the right coating technology requires balancing its capabilities against its limitations. Use these points as a guide to determine if CVD aligns with your project's goals.

- If your primary focus is ultimate film quality on a heat-resistant substrate: CVD remains a top choice despite its complexity, as it produces exceptionally pure, dense, and conformal coatings.

- If you are working with temperature-sensitive materials like polymers or certain alloys: You must consider alternatives like Plasma-Enhanced CVD (PECVD) or Physical Vapor Deposition (PVD), which operate at lower temperatures.

- If you need to coat very large components or require high-volume production: The batch nature and chamber size limitations of CVD may make other coating methods more economical and practical.

- If operational simplicity and on-site processing are critical: The logistical, safety, and cost overhead of CVD makes it less suitable; simpler methods might be a better fit if they meet your quality needs.

By weighing these practical constraints against your material and performance goals, you can make a clear and confident decision.

Summary Table:

| Challenge | Limitation Details |

|---|---|

| High-Temperature Barrier | Incompatible with heat-sensitive materials like polymers, limiting substrate options. |

| Inability to Selectively Mask | Coats all exposed surfaces, requiring pre-assembly coating and adding manufacturing steps. |

| Physical and Scale Limitations | Chamber size restricts part dimensions and batch processing reduces throughput. |

| Process Complexity | Requires precise control of temperature, pressure, and gas flow to avoid film defects. |

| Safety and Environmental Concerns | Involves hazardous gases and byproducts, needing specialized handling and waste management. |

| High Costs | Significant capital investment and ongoing operational expenses for energy and maintenance. |

| Logistical Hurdles | Often requires off-site processing, increasing lead times and disassembly needs. |

Struggling with CVD limitations for your lab's high-temperature applications? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. With exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs, ensuring efficient, safe, and cost-effective processes. Contact us today to discuss how we can enhance your coating workflows and overcome these challenges!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures