At its core, Chemical Vapor Deposition (CVD) is an exceptionally versatile technique capable of depositing a broad spectrum of high-performance ceramic materials. The most common families include carbides (like silicon carbide), nitrides (like titanium nitride), oxides (like aluminum oxide), and borides. These materials are foundational for creating thin films and coatings valued for their exceptional hardness, thermal stability, and specific electrical properties.

The true power of CVD lies not just in the variety of ceramics it can deposit, but in its ability to precisely control the film's purity, density, and microstructure. This allows engineers to tailor a material's properties to solve a specific performance challenge, from wear resistance on cutting tools to electrical insulation in microchips.

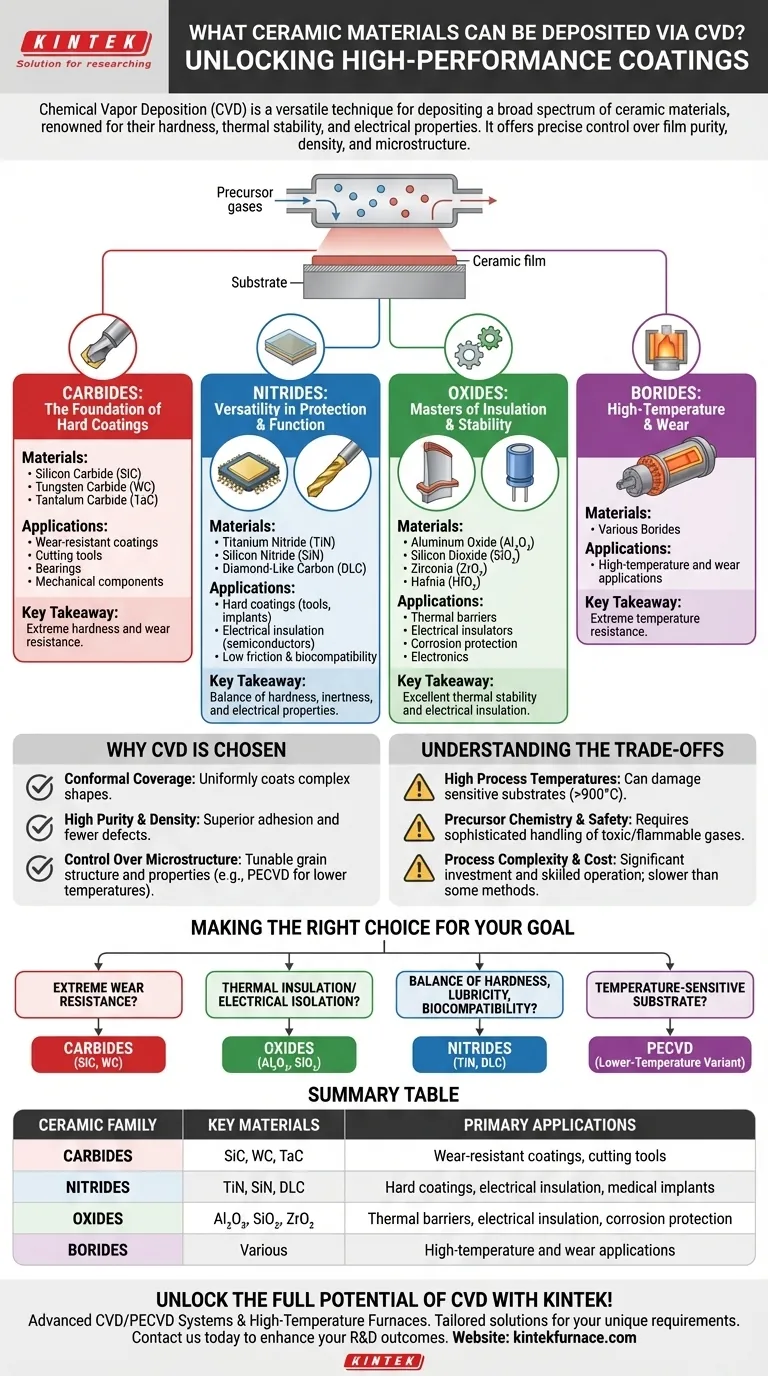

The Major Ceramic Families Deposited by CVD

CVD is not a single process but a family of techniques that use chemical reactions from gaseous precursors to form a solid film on a substrate. This method is ideal for creating dense, high-purity ceramic layers.

Carbides: The Foundation of Hard Coatings

Carbides are compounds of carbon with a less electronegative element, renowned for their extreme hardness and wear resistance.

Materials like Silicon Carbide (SiC), Tungsten Carbide (WC), and Tantalum Carbide (TaC) are staples of CVD processing. They are frequently used as protective coatings on cutting tools, bearings, and other components subject to intense mechanical wear.

Nitrides: Versatility in Protection and Function

Nitrides offer a fantastic balance of properties, including hardness, chemical inertness, and useful electrical characteristics.

Titanium Nitride (TiN) is a classic example, providing a hard, gold-colored coating for tools and medical implants. Silicon Nitride (SiN) is a critical dielectric insulator in the semiconductor industry, while Diamond-Like Carbon (DLC), often containing nitrogen, offers a unique combination of hardness and low friction.

Oxides: Masters of Insulation and Stability

Oxide ceramics are defined by their excellent thermal stability and electrical insulation properties, making them indispensable in electronics and high-temperature applications.

CVD is used to deposit films like Aluminum Oxide (Al2O3 or Alumina), Silicon Dioxide (SiO2), Zirconia (ZrO2), and Hafnia (HfO2). These serve as thermal barriers, electrical insulators, and protective layers against corrosion.

Why CVD is Chosen for Ceramic Deposition

While other methods exist, CVD offers unique advantages for creating high-performance ceramic films. The choice to use CVD is often driven by the need for superior film quality that other processes cannot achieve.

Conformal Coverage on Complex Shapes

Because the precursors are in a gas phase, they can penetrate and uniformly coat highly complex and intricate surfaces. This "conformal coverage" is a key advantage over line-of-sight techniques like Physical Vapor Deposition (PVD).

High Purity and Density

The controlled chemical reaction at the substrate surface produces exceptionally pure and dense films. This results in superior adhesion and fewer defects, leading to more reliable performance in demanding applications.

Control Over Microstructure

By carefully adjusting process parameters like temperature, pressure, and gas composition, operators can tune the final film's grain structure and properties. Variants like Plasma-Enhanced CVD (PECVD) use plasma to enable deposition at lower temperatures, broadening the range of compatible substrate materials.

Understanding the Trade-offs

Despite its power, CVD is not a universal solution. Understanding its limitations is critical for making an informed decision.

High Process Temperatures

Traditional thermal CVD often requires very high temperatures (over 900°C) to drive the chemical reactions. This can damage or deform temperature-sensitive substrates, such as certain plastics or tempered metals.

Precursor Chemistry and Safety

The gaseous chemicals (precursors) used in CVD can be highly toxic, flammable, or corrosive. This necessitates sophisticated and expensive safety protocols, gas handling systems, and exhaust treatment.

Process Complexity and Cost

CVD reactors are complex machines that require significant capital investment and skilled operators. The overall process can be slower and more expensive than simpler coating methods, making it best suited for high-value applications where performance is paramount.

Making the Right Choice for Your Goal

Selecting the appropriate CVD ceramic depends entirely on the primary performance requirement of your component.

- If your primary focus is extreme wear resistance and hardness: Your best choices are carbides like Silicon Carbide (SiC) and Tungsten Carbide (WC).

- If your primary focus is thermal insulation or electrical isolation: You should specify oxides like Alumina (Al2O3) or Silicon Dioxide (SiO2).

- If your primary focus is a balance of hardness, lubricity, and biocompatibility: Look to nitrides like Titanium Nitride (TiN) or Diamond-Like Carbon (DLC).

- If you are coating a temperature-sensitive substrate: You must investigate lower-temperature variants like Plasma-Enhanced CVD (PECVD) to avoid damaging your part.

By understanding these material classes and their associated trade-offs, you can effectively leverage CVD to create high-performance ceramic coatings tailored to your specific engineering challenge.

Summary Table:

| Ceramic Family | Key Materials | Primary Applications |

|---|---|---|

| Carbides | SiC, WC, TaC | Wear-resistant coatings, cutting tools |

| Nitrides | TiN, SiN, DLC | Hard coatings, electrical insulation, medical implants |

| Oxides | Al2O3, SiO2, ZrO2 | Thermal barriers, electrical insulation, corrosion protection |

| Borides | Various | High-temperature and wear applications |

Unlock the full potential of CVD for your laboratory with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for ceramic coatings. Contact us today to discuss how our tailored solutions can enhance your research and development outcomes!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What are the applications of PECVD? Unlock Low-Temperature Thin-Film Deposition

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods