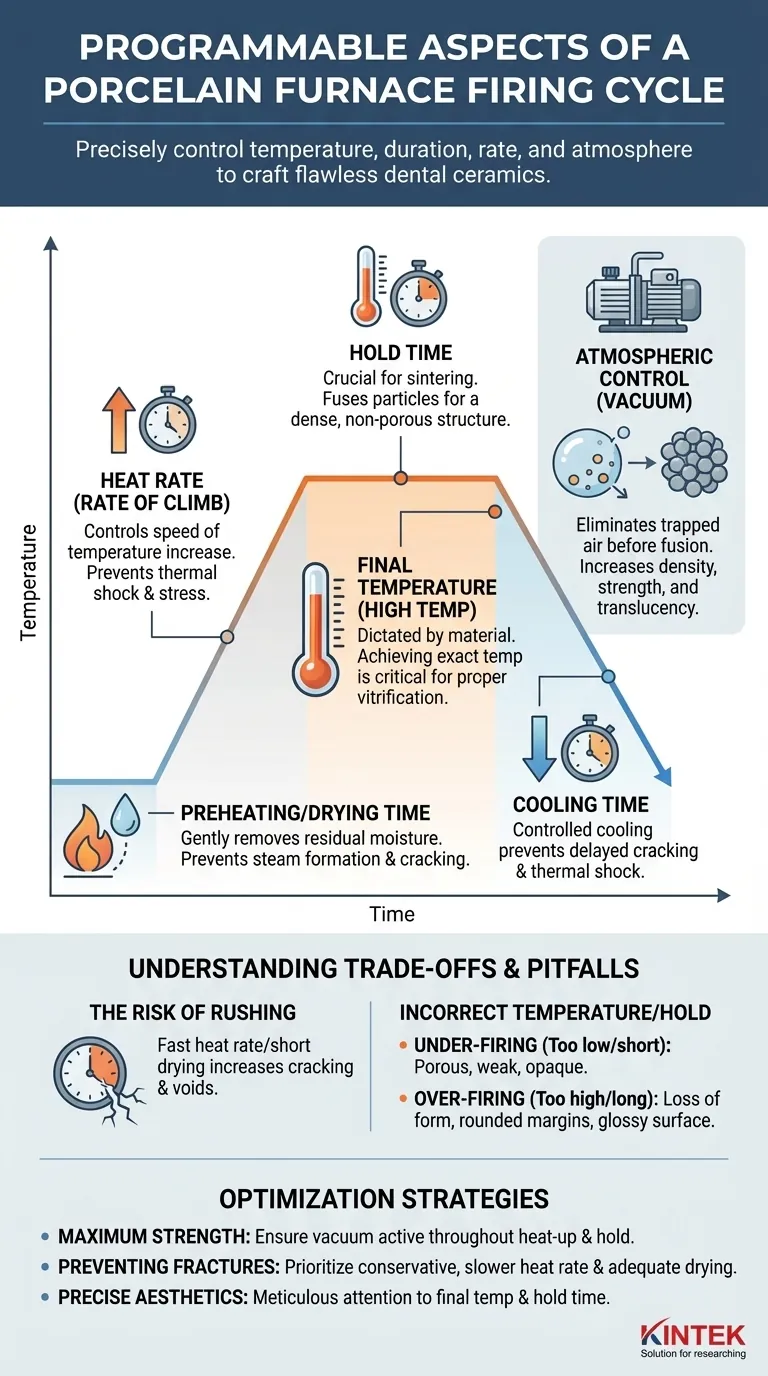

In short, nearly every critical aspect of a porcelain furnace's firing cycle is programmable. You can precisely control temperatures, the duration of each stage, the rate of temperature change, and the atmospheric environment to perfectly match the requirements of any dental ceramic you are working with.

The ability to program the firing cycle is not just a feature; it is the core mechanism that allows a dental technician to control the physical and aesthetic properties of a ceramic restoration. Mastering these parameters is the key to transforming raw porcelain powder into a strong, dense, and lifelike final product.

Deconstructing the Firing Cycle: Key Programmable Parameters

A firing cycle is a carefully choreographed thermal journey. Each programmable stage serves a distinct purpose in ensuring the final restoration is free of defects and meets a high aesthetic standard.

Temperature Control: The Foundation of Sintering

The most fundamental parameter is temperature. You must program the final or "high" temperature that the furnace will reach.

This temperature is dictated entirely by the specific ceramic material being used—whether it's an opaquer, dentine porcelain, a glaze, or a material requiring crystallization. Hitting this exact temperature is critical for achieving proper sintering (vitrification).

Time Management: Controlling the Thermal Journey

How the furnace gets to and from its high temperature is just as important as the temperature itself. This is controlled by a series of time-based parameters.

- Preheating/Drying Time: This initial low-temperature stage is programmed to gently and completely remove any residual moisture from the porcelain build-up. Skipping this or doing it too quickly can cause steam to form internally, leading to "popping" or cracking.

- Heat Rate (Rate of Climb): This setting controls how fast the temperature increases, typically measured in degrees per minute. A controlled heat rate prevents thermal shock, which can cause stress and fractures in the ceramic.

- Hold Time: Once the furnace reaches the programmed high temperature, the hold time dictates how long it stays there. This is when the crucial process of sintering occurs, as porcelain particles fuse together to create a dense, non-porous structure.

- Cooling Time: Just as with heating, cooling must be controlled. Some furnaces allow for programmed cooling rates to prevent thermal shock on the way down, minimizing the risk of delayed cracking.

Atmospheric Control: The Role of the Vacuum

Many modern furnaces operate under a vacuum for a significant portion of the cycle. You can program precisely when the vacuum pump turns on and when it is released.

The purpose of the vacuum is to remove air trapped between porcelain particles before they fuse. This eliminates bubbles, dramatically increases the final density and strength of the restoration, and improves its optical properties and translucency.

Understanding the Trade-offs and Common Pitfalls

While pre-set programs are a reliable starting point, understanding the consequences of incorrect parameters is vital for troubleshooting and custom work.

The Risk of Rushing the Cycle

Using a heat rate that is too fast or a drying time that is too short can save time, but it dramatically increases the risk of cracks and internal voids from trapped steam and thermal shock.

Incorrect Temperature or Hold Time

Under-firing (temperature too low or hold time too short) results in incomplete sintering. The restoration will be porous, weak, opaque, and will not have the desired shade.

Over-firing (temperature too high or hold time too long) causes the ceramic to begin to flow (pyroplastic flow). This leads to a loss of anatomical form, rounded margins, and an unnaturally glossy or "glassy" surface that lacks texture.

Mismanaging the Vacuum

Releasing the vacuum too early in the cycle, before the porcelain has adequately fused, will allow air to re-enter and create porosity. Firing without a vacuum will result in a weak and cloudy restoration.

Optimizing Your Firing Program

Use the manufacturer's instructions for a given ceramic as your baseline, but adjust based on your observations and goals.

- If your primary focus is maximum strength and density: Ensure your program includes a proper vacuum cycle that is active throughout the heat-up and hold time, releasing just before cooling begins.

- If your primary focus is preventing fractures: Prioritize a conservative, slower heat rate and allow for adequate pre-drying time, especially with larger or thicker restorations.

- If your primary focus is achieving precise aesthetics: Pay meticulous attention to the final temperature and hold time, as these have the greatest impact on surface texture, translucency, and vitality.

Mastering these parameters transforms the furnace from a simple oven into a precision instrument for creating exceptional and durable restorations.

Summary Table:

| Programmable Parameter | Purpose | Impact on Restoration |

|---|---|---|

| Temperature Control | Achieve precise sintering for material fusion | Ensures strength, density, and correct shade |

| Preheating/Drying Time | Remove moisture to prevent cracking | Avoids internal defects like popping or voids |

| Heat Rate | Control temperature increase to prevent thermal shock | Reduces risk of fractures and stress |

| Hold Time | Allow sintering at high temperature | Creates dense, non-porous structure |

| Cooling Time | Manage temperature decrease to avoid delayed cracking | Maintains integrity and shape |

| Atmospheric Control (Vacuum) | Eliminate air bubbles for better optical properties | Increases translucency and strength |

Ready to elevate your dental lab's capabilities with precision porcelain furnaces? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and restoration requirements. Achieve superior results in strength, aesthetics, and efficiency—contact us today to discuss how our furnaces can transform your workflow and deliver flawless dental ceramics!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique