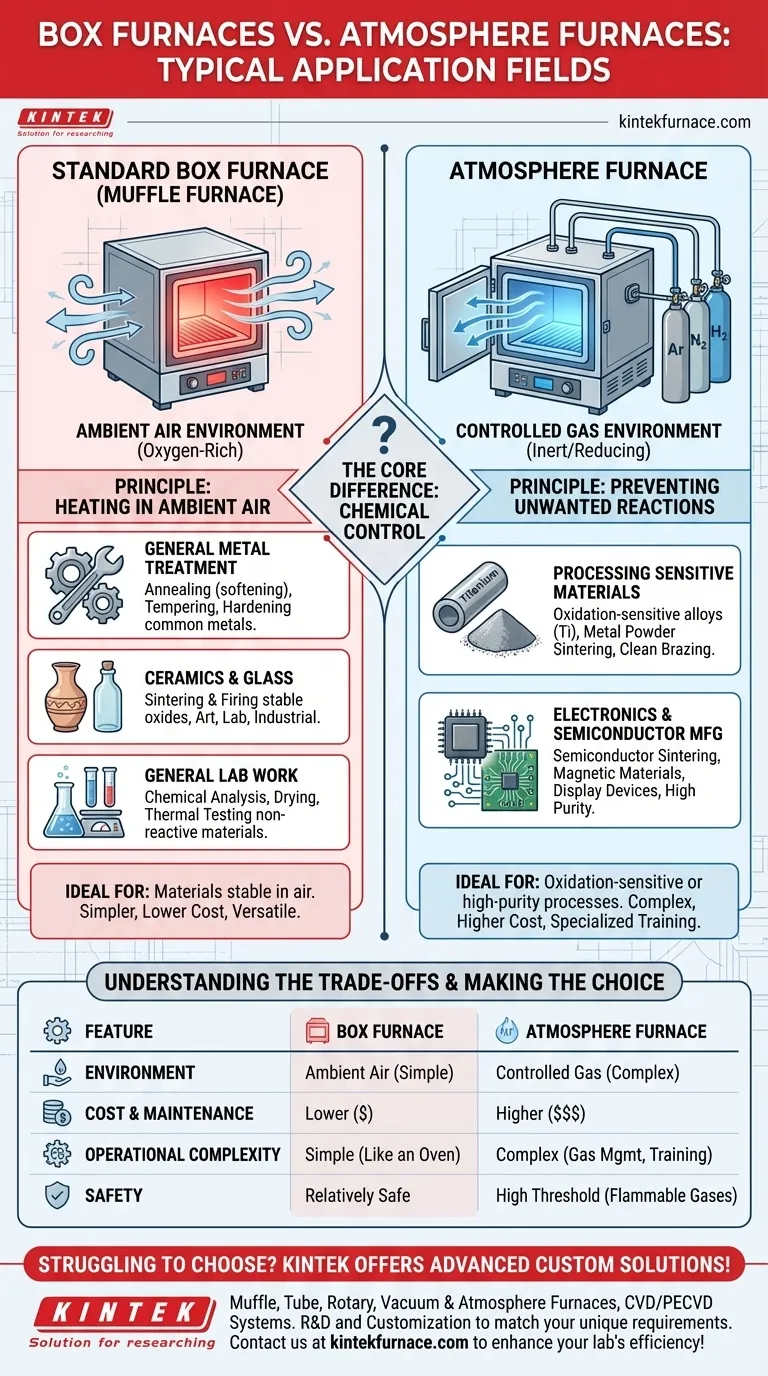

In essence, box furnaces are general-purpose workhorses for heating materials in air, while atmosphere furnaces are specialized tools for processes that require a controlled gaseous environment. Box furnaces are the go-to solution for basic tasks like annealing common metals, sintering stable ceramics, or general laboratory sample testing. Atmosphere furnaces, however, are indispensable for sensitive applications like processing titanium alloys, manufacturing semiconductor components, or advanced powder metallurgy, where exposure to oxygen would ruin the final product.

The choice between a box furnace and an atmosphere furnace is not about temperature, but about chemical control. The critical question you must answer is: will your material react negatively with the ambient air at high temperatures? If the answer is yes, you need the protective, controlled environment of an atmosphere furnace.

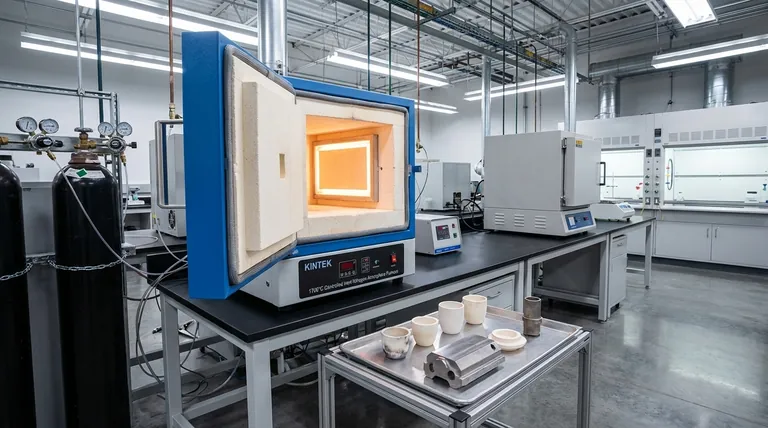

When to Use a Standard Box Furnace

A box furnace, also known as a muffle furnace, is the most common type of furnace for a reason. It is straightforward, reliable, and effective for any process where the material is stable when heated in normal air.

The Principle: Heating in Ambient Air

A box furnace operates by simply heating its chamber. The environment inside is the same as the air outside, composed primarily of nitrogen and oxygen.

This makes it the default choice when there is no risk of undesirable oxidation or other chemical reactions with the air.

Common Applications: General Metal Treatment

For many common metals, a box furnace is perfectly sufficient for heat treatment processes.

These include annealing to soften metals and relieve internal stress, tempering to improve toughness after hardening, and hardening to increase the strength of steel parts.

Common Applications: Ceramics and Glass

The production of many ceramic and glass materials involves firing at high temperatures to achieve densification and strength.

Since these materials are often oxides themselves, heating them in an oxygen-rich environment is not a problem. This makes box furnaces ideal for ceramic sintering and glass firing in labs, art studios, and industrial settings.

Common Applications: General Lab Work

Box furnaces are fixtures in research and quality control labs. Their simplicity and versatility make them perfect for routine tasks.

This includes chemical analysis, drying samples, or performing basic thermal tests on a wide variety of non-reactive materials.

Why an Atmosphere Furnace is Essential

An atmosphere furnace provides complete control over the gaseous environment inside the heating chamber. This capability is not a luxury; for many advanced processes, it is an absolute requirement.

The Principle: Preventing Unwanted Reactions

Think of the furnace environment like food packaging. Some items are fine on an open shelf (a box furnace), but sensitive items require vacuum sealing or a nitrogen flush to prevent spoilage (an atmosphere furnace).

By replacing the air with a specific gas (like argon, nitrogen, or hydrogen), an atmosphere furnace prevents oxidation, removes contaminants, and can even create a chemically reactive environment to aid the process.

Key Application: Processing Sensitive Materials

Many high-performance metals and alloys are highly reactive with oxygen at high temperatures, forming a brittle oxide layer that degrades their properties.

An atmosphere furnace is required for processing oxidation-sensitive metals like titanium alloys, sintering metal powders without them turning to rust, and brazing components where a clean, oxide-free surface is critical for a strong bond.

Key Application: Electronics and Semiconductor Manufacturing

The manufacturing of electronic components demands extreme purity. Even a microscopic layer of oxidation can cause a device to fail.

Atmosphere furnaces are used for sintering semiconductor components, preparing magnetic materials, and manufacturing display devices in an inert or reducing environment to ensure perfect material integrity.

Understanding the Trade-offs

Choosing the right furnace involves balancing process requirements against operational realities. The added capability of an atmosphere furnace comes with significant trade-offs.

Operational Simplicity vs. Complexity

A box furnace is often as simple to operate as a kitchen oven. In contrast, an atmosphere furnace is a complex system that requires managing gas supplies, flow rates, and safety interlocks.

Operating an atmosphere furnace requires specialized training to handle the process parameters and associated safety protocols correctly.

Cost and Maintenance

Box furnaces have a lower initial purchase price and are generally cheaper to maintain due to their simpler construction.

Atmosphere furnaces have higher upfront costs and ongoing operational expenses, including the continuous consumption of process gases and maintenance of gas delivery and monitoring systems.

Safety Considerations

While any high-temperature equipment requires caution, box furnaces are relatively safe.

Atmosphere furnaces often use flammable or explosive gases like hydrogen, which necessitates a much higher safety threshold. This includes mandatory gas monitoring, explosion-proof devices, and a strictly controlled operating environment.

Making the Right Choice for Your Process

Your final decision must be guided by the specific chemical and physical requirements of your material and process.

- If your primary focus is general-purpose heat treatment or lab testing: A standard box furnace offers the best combination of simplicity, versatility, and cost-effectiveness for materials that are stable in air.

- If your primary focus is preventing oxidation or surface reactions: An atmosphere furnace is non-negotiable for protecting sensitive materials like titanium, copper alloys, or fine metal powders.

- If your primary focus is precision electronics or advanced materials research: The ultra-clean, controlled environment of an atmosphere furnace is required to achieve the necessary material purity and performance.

Ultimately, selecting the right furnace comes down to understanding the chemical needs of your material at temperature.

Summary Table:

| Feature | Box Furnace | Atmosphere Furnace |

|---|---|---|

| Environment | Ambient air (oxygen-rich) | Controlled gas (e.g., argon, nitrogen) |

| Key Applications | Annealing metals, sintering ceramics, lab testing | Processing titanium alloys, semiconductor manufacturing, powder metallurgy |

| Cost & Complexity | Lower cost, simpler operation | Higher cost, requires gas management and training |

| Ideal For | Materials stable in air | Oxidation-sensitive or high-purity processes |

Struggling to choose the right furnace for your lab's unique needs? KINTEK specializes in advanced high-temperature solutions, offering Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and deep customization capabilities, we can tailor equipment to precisely match your experimental requirements—whether for general heat treatment or sensitive material processing. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios