At their core, all modern kilns rely on one of two primary power sources: gas or electricity. While both serve the fundamental purpose of generating heat, the choice between them dictates nearly every aspect of the firing process, from the final look of your glazes to the very nature of your workflow and the setup of your studio.

The decision between gas and electric is not merely about utility connections. It is a fundamental choice between predictable automation (electric) and atmospheric control (gas), which directly influences the artistic results you can achieve.

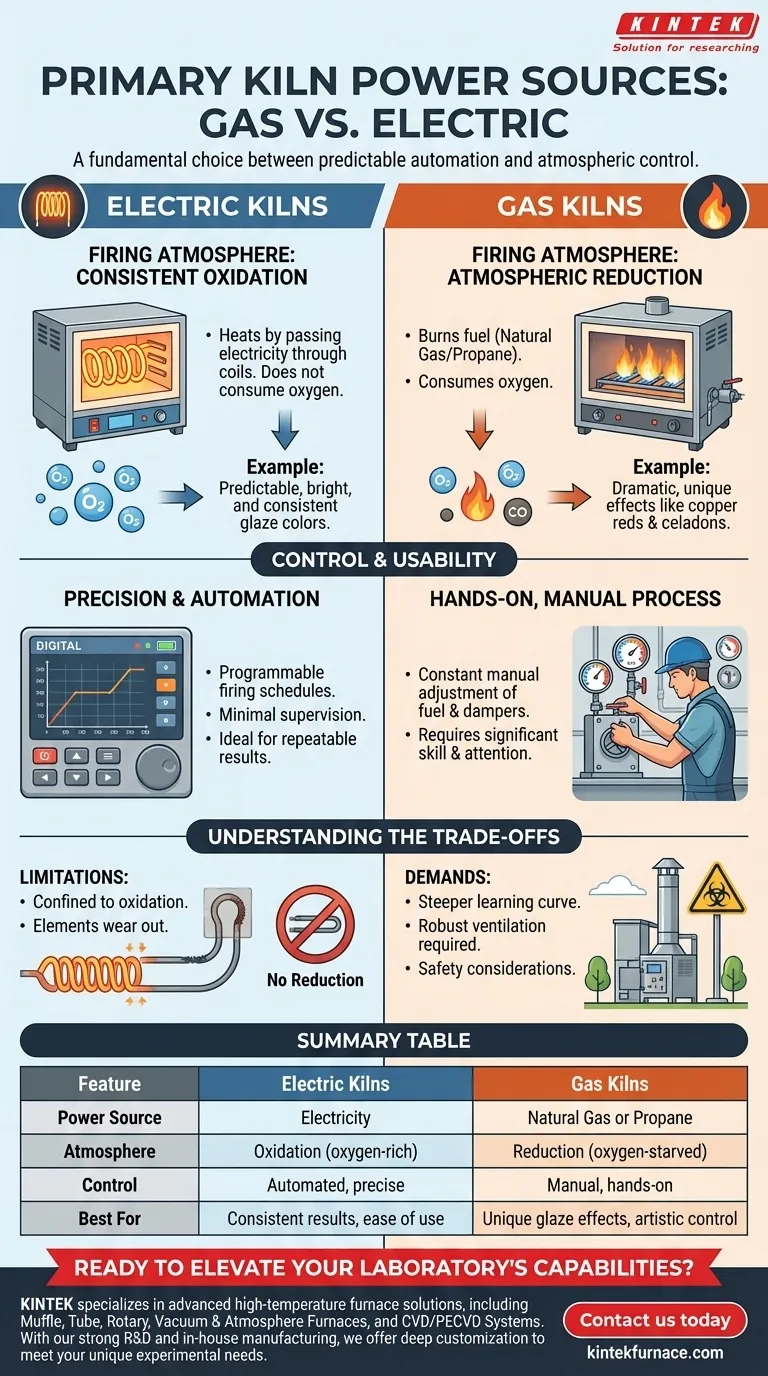

The Defining Difference: Firing Atmosphere

The most critical distinction between gas and electric kilns is their effect on the kiln's internal atmosphere. This atmosphere—either rich with oxygen or starved of it—chemically alters your clays and glazes.

Electric Kilns: The Consistency of Oxidation

Electric kilns heat by passing electricity through coiled elements, which glow red hot. This process does not consume oxygen.

As a result, the default atmosphere in an electric kiln is oxidation, meaning it is rich in oxygen. This environment produces predictable, bright, and consistent glaze colors, behaving exactly as the manufacturer intended.

Gas Kilns: The Power of Reduction

Gas kilns burn a fuel source, typically natural gas or propane, to generate heat. This combustion process actively consumes oxygen from the kiln chamber.

By carefully controlling the fuel-to-air ratio, an operator can create a reduction atmosphere, which is starved of oxygen. This environment forces glazes and clay bodies to seek out oxygen molecules, causing dramatic and often unique chemical changes, such as the brilliant reds from copper or the rich, earthy tones in celadons.

Control and Usability

Beyond atmosphere, the two kiln types offer vastly different user experiences. Your choice here depends on your desire for automation versus hands-on control.

Electric Kilns: Precision and Automation

Modern electric kilns are almost universally controlled by digital pyrometers and programmable controllers.

You can program a precise firing schedule—dictating the rate of temperature climb, holding times, and cooling—and the kiln will execute it perfectly with minimal supervision. This makes them exceptionally easy to use and ideal for achieving repeatable results.

Gas Kilns: A Hands-On, Manual Process

A gas kiln requires constant manual adjustment. The operator must actively manage the gas flow and dampers to control the temperature rise and the atmospheric conditions.

This process is a skill learned over time, often described as an art in itself. It offers unparalleled control for those who want to "play" with the firing process, but it demands significant attention and expertise.

Understanding the Trade-offs

Neither option is universally superior; they are simply different tools for different goals. Understanding their inherent limitations is key to making an informed decision.

The Limits of Electric Kilns

The primary trade-off with an electric kiln is its confinement to oxidation firing. While some effects can be simulated, achieving a true, deep reduction atmosphere is not possible. Furthermore, the heating elements are consumable parts that will eventually wear out and require replacement.

The Demands of Gas Kilns

Gas kilns carry a steeper learning curve and significant safety considerations. They require robust ventilation systems to safely exhaust carbon monoxide and other fumes, meaning they are almost always installed outdoors or in a dedicated, open-air structure. They are also less "set-and-forget," requiring your presence and skill throughout the firing.

Making the Right Choice for Your Work

To select the right kiln, you must first define your goals as an artist or craftsperson. The technical specifications are secondary to your creative intent.

- If your primary focus is ease of use and consistent results: An electric kiln's automated, predictable oxidation environment is the clear choice.

- If your primary focus is achieving unique, varied glaze effects: A gas kiln provides the atmospheric control necessary for reduction firing and its associated artistic possibilities.

- If you are setting up in a home or small studio: An electric kiln is often the only practical option due to its smaller footprint and lack of ventilation requirements.

By understanding that you are choosing a process, not just a machine, you can confidently select the kiln that will best serve your artistic vision.

Summary Table:

| Feature | Electric Kilns | Gas Kilns |

|---|---|---|

| Power Source | Electricity | Natural Gas or Propane |

| Atmosphere | Oxidation (oxygen-rich) | Reduction (oxygen-starved) |

| Control | Automated, precise | Manual, hands-on |

| Best For | Consistent results, ease of use | Unique glaze effects, artistic control |

Ready to elevate your laboratory's capabilities? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your research and production efficiency!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency