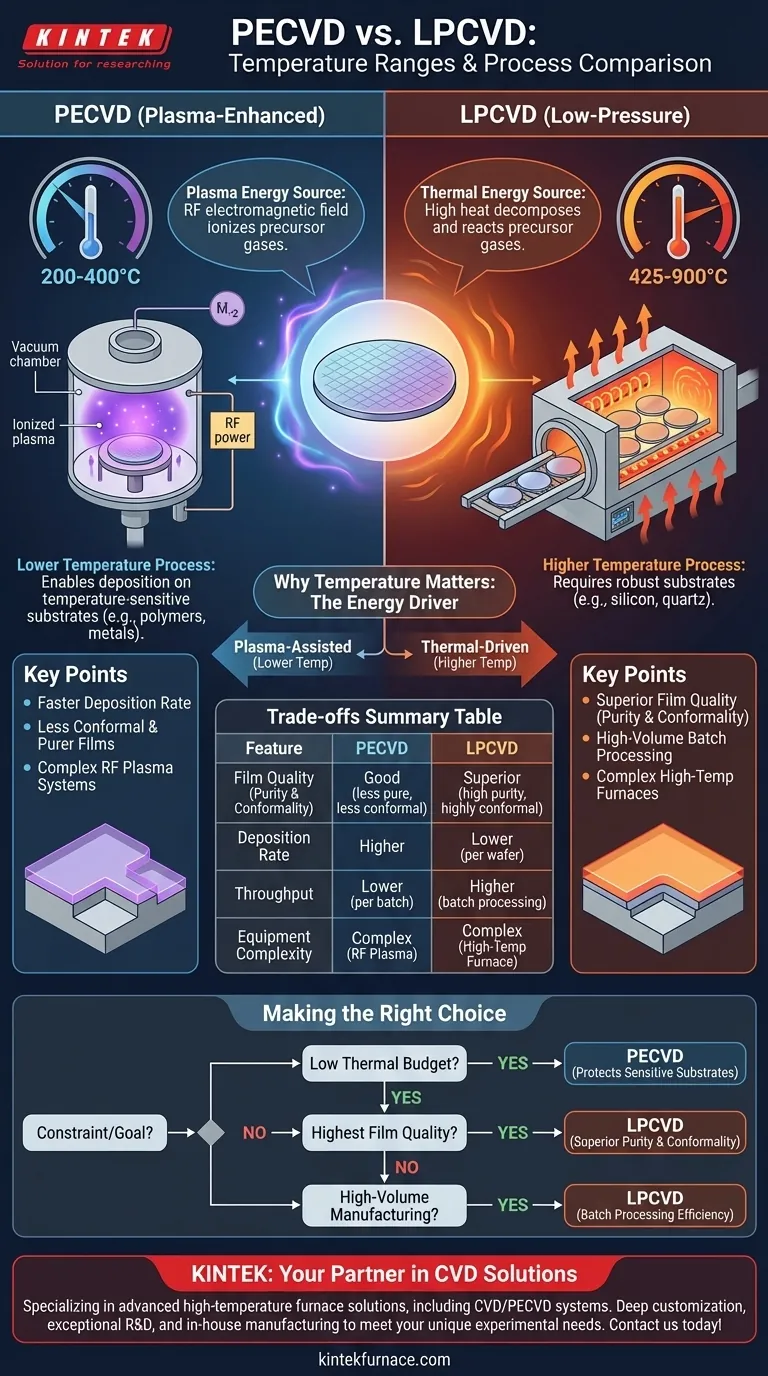

In chemical vapor deposition, PECVD (Plasma-Enhanced Chemical Vapor Deposition) operates at significantly lower temperatures, typically between 200-400°C. In contrast, LPCVD (Low-Pressure Chemical Vapor Deposition) requires a much higher thermal budget, with processes running anywhere from 425-900°C. This fundamental temperature difference is a direct result of how each process supplies the energy needed to drive the deposition reaction.

The choice between LPCVD and PECVD is not merely about temperature, but about the energy source that dictates it. LPCVD's reliance on thermal energy demands high heat but yields superior films, while PECVD's use of plasma energy enables low-temperature processing that is essential for temperature-sensitive substrates.

Why Temperature is the Defining Factor

The operational temperature is the most critical distinction between these two powerful deposition techniques. It directly influences everything from film quality to which materials you can use as a substrate. The reason for the vast temperature difference lies in the core mechanism of each process.

LPCVD: The Thermal-Driven Approach

LPCVD relies exclusively on thermal energy to initiate and sustain the chemical reactions. Precursor gases introduced into the vacuum chamber must be heated to a temperature high enough to cause them to decompose and react on the substrate surface.

This high-temperature environment (425-900°C) is necessary to provide the activation energy for the surface reactions. The result is typically a very high-purity, dense, and highly conformal film, as the heat allows atoms to migrate on the surface to find low-energy lattice sites.

PECVD: The Plasma-Assisted Alternative

PECVD circumvents the need for high temperatures by introducing another form of energy: plasma. An electromagnetic field (typically Radio Frequency) is used to ionize the precursor gases, creating a highly reactive plasma.

This plasma contains ions, radicals, and other excited species that are far more reactive than the original gas molecules. Because these species are already energized, the deposition reaction can proceed at much lower temperatures (200-400°C). The energy is supplied by the plasma, not just the heat.

The Impact on Substrate Compatibility

The low operating temperature of PECVD is its single greatest advantage. It allows for the deposition of films onto substrates that cannot withstand high thermal loads.

This includes substrates with previously fabricated metal layers (like aluminum, which melts at ~660°C), polymers, or other temperature-sensitive devices. LPCVD, due to its high heat, is largely restricted to thermally robust substrates like bare silicon or quartz wafers.

Understanding the Trade-offs

Choosing a deposition method is a matter of balancing competing priorities. The lower temperature of PECVD comes with specific compromises compared to the high-quality films produced by LPCVD.

Film Quality: Purity and Conformality

LPCVD is the gold standard for film quality. The high-temperature process yields films with excellent stoichiometry (the correct ratio of elements), low impurity levels, and superior conformality (the ability to evenly coat complex, high-aspect-ratio trenches and steps).

PECVD films, by contrast, often have hydrogen incorporated into them, as precursors like silane (SiH₄) are not fully dissociated. This can affect the film's electrical and optical properties. PECVD conformality is also generally poorer than that of LPCVD.

Deposition Rate and Throughput

PECVD processes can often achieve higher deposition rates than LPCVD. This is because the plasma creates a high concentration of reactive species near the substrate surface.

However, LPCVD systems are typically large batch furnaces capable of processing hundreds of wafers simultaneously. This high-volume batch processing often gives LPCVD a significant advantage in overall throughput for mass production, despite a slower per-wafer deposition rate.

Equipment and Process Complexity

While the LPCVD reaction mechanism is simpler (heat-driven), the equipment requires robust high-temperature furnaces and handling.

PECVD systems do not require such extreme heating but involve complex RF plasma generation systems, including matching networks and power supplies, adding a different layer of complexity to the process control.

Making the Right Choice for Your Application

The decision to use PECVD or LPCVD is fundamentally a strategic engineering choice based on the constraints and goals of your specific project.

- If your primary focus is substrate compatibility and a low thermal budget: PECVD is the clear and often only choice, as it protects temperature-sensitive materials already on your wafer.

- If your primary focus is the highest film quality, purity, and conformality: LPCVD is the superior method, provided your substrate can withstand the required high processing temperatures.

- If your primary focus is high-volume manufacturing on robust substrates: LPCVD in a batch furnace configuration often provides the most cost-effective solution for producing high-quality dielectric or polysilicon films.

Ultimately, the choice between PECVD and LPCVD is a strategic decision dictated by your substrate's limitations and your final film's performance requirements.

Summary Table:

| Process | Temperature Range | Key Energy Source | Ideal For |

|---|---|---|---|

| PECVD | 200-400°C | Plasma | Temperature-sensitive substrates, faster deposition |

| LPCVD | 425-900°C | Thermal | High-purity films, conformal coatings, batch processing |

Struggling to choose the right CVD process for your lab? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs—whether you're working with temperature-sensitive materials or require superior film quality. Contact us today to discuss how our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems can enhance your research and production efficiency!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings