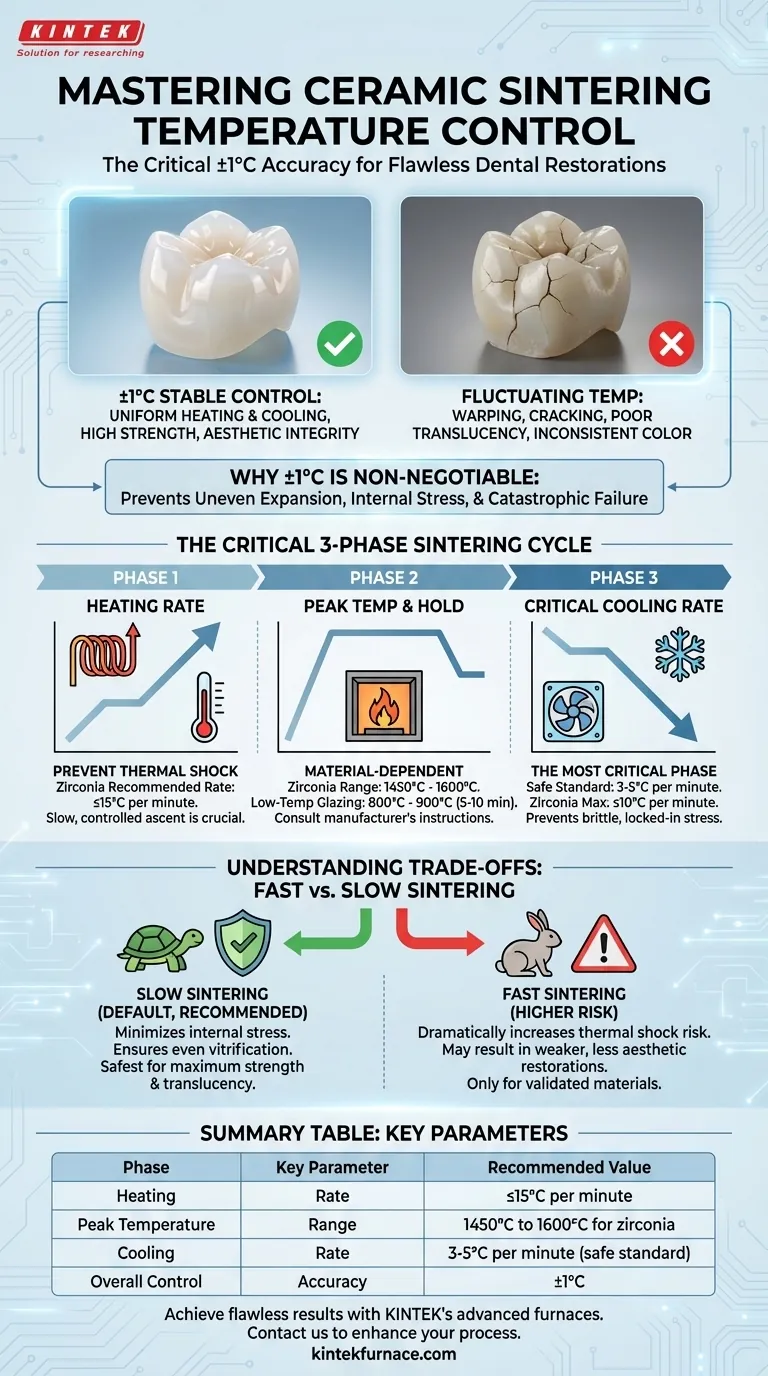

To achieve reliable, high-quality ceramic restorations, your sintering furnace must maintain a temperature control accuracy of ±1°C throughout the entire heating and cooling cycle. This level of precision is the absolute minimum requirement to prevent common failures such as deformation, decreased transparency, inconsistent color, and cracking.

Sintering success is not defined by simply reaching a peak temperature. It is achieved by precisely managing the entire thermal profile—the rate of heating, the stability of the hold, and critically, the rate of cooling. Each phase is essential for ensuring the structural and aesthetic integrity of the final ceramic restoration.

Why ±1°C Accuracy is Non-Negotiable

This strict tolerance is not an arbitrary number. It directly correlates to predictable outcomes and the prevention of costly failures.

The Impact on Structural Integrity

Minor temperature fluctuations can cause uneven expansion and contraction within the ceramic material. This introduces internal stress, which is the primary cause of warping, deformation, and microcracks that can lead to catastrophic failure later.

A stable ±1°C environment ensures the material heats and cools as a uniform body, preserving its intended shape and strength.

The Impact on Aesthetics

For translucent materials like glass ceramics, temperature deviations can ruin the final result. Overheating can cause the glass phase to flow unevenly, creating cloudy or opaque spots.

Similarly, uneven temperature distribution across the sintering tray can lead to noticeable color and gloss variations in the final restoration. Precise control guarantees consistent, predictable aesthetics.

Deconstructing the Sintering Cycle

A successful sintering program is a carefully controlled three-phase process. You must manage the parameters for each phase based on the specific material being used.

Phase 1: The Heating Rate

The initial heating phase must be slow enough to avoid thermal shock. Rapid heating can cause the outer surface of the ceramic to heat much faster than the core, leading to stress and cracks.

For zirconia, a heating rate of ≤15°C per minute is the recommended maximum to ensure thermal stability.

Phase 2: Peak Temperature and Hold Time

This is the most material-dependent phase. Zirconia typically requires a peak temperature between 1450°C and 1600°C, while low-temperature glazing is fired between 800°C and 900°C for 5-10 minutes.

Always consult the ceramic manufacturer's instructions for the precise peak temperature and hold time. Using a separate, validated program for each distinct material is essential.

Phase 3: The Critical Cooling Rate

The cooling phase is arguably the most critical for preventing failure. Cooling too quickly locks internal stress into the material, making it brittle and prone to cracking long after it has left the furnace.

A slow, controlled cooling rate of 3-5°C per minute is a safe standard for most ceramics. For zirconia, the rate should not exceed 10°C per minute.

Understanding the Trade-offs: Fast vs. Slow Sintering

Your furnace offers both fast and slow sintering modes, but they serve very different purposes and carry different levels of risk.

When to Use Slow Sintering (The Default)

Slow sintering is the recommended standard for all high-quality ceramic work. This mode adheres to the controlled heating and cooling rates necessary to minimize internal stress and ensure even vitrification of the glass phase.

It is the safest path to achieving maximum strength, proper translucency, and dimensional accuracy.

The Risks of Fast Sintering

Fast sintering dramatically increases the risk of thermal shock, internal stress, and incomplete phase transformation. This can result in a weaker, less esthetic restoration that is prone to premature failure.

Only use the fast sintering mode for materials that have been explicitly developed and validated for rapid cycles by their manufacturer. Even then, you should conduct your own tests to confirm the results meet your quality standards.

How to Apply This to Your Process

Your approach should be guided by your primary objective for the restoration.

- If your primary focus is maximum quality and reliability: Always use the slow sintering mode and a conservative cooling rate of 3-5°C per minute to guarantee the best possible outcome.

- If your primary focus is sintering zirconia: Adhere strictly to the manufacturer's peak temperature, but maintain control with a heating rate of ≤15°C/min and a cooling rate of ≤10°C/min.

- If your primary focus is efficiency: Only use fast sintering for materials explicitly designed for it, and always validate the results before using it for a final patient restoration.

Mastering the thermal cycle transforms your furnace from a simple oven into a predictable and reliable manufacturing partner.

Summary Table:

| Phase | Key Parameter | Recommended Value |

|---|---|---|

| Heating | Rate | ≤15°C per minute |

| Peak Temperature | Range | 1450°C to 1600°C for zirconia |

| Cooling | Rate | 3-5°C per minute (safe standard) |

| Overall Control | Accuracy | ±1°C |

Achieve flawless ceramic sintering with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide dental labs with precise high-temperature furnaces like Muffle, Tube, and Vacuum & Atmosphere models, tailored to your unique needs through deep customization. Ensure consistent, high-quality restorations—contact us today to discuss how our expertise can enhance your process!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations