In short, the primary heat treatment processes performed in a box furnace are annealing, hardening, and tempering. These furnaces are also widely used for more specialized applications, including solution treatment for alloys, sintering of powdered metals, and brazing components together. The specific process chosen depends entirely on the material being treated and the desired final properties, such as increased hardness, improved ductility, or reduced internal stress.

A box furnace is fundamentally a tool for executing precise, pre-programmed thermal cycles on a batch of materials. Its value lies not just in its ability to get hot, but in its capacity for controlled heating, soaking at a specific temperature, and controlled cooling to deliberately re-engineer a material's internal microstructure.

The Core Principle: Controlled Thermal Cycles

A box furnace operates on a simple but critical principle: providing a highly uniform and controllable heating environment. It is an intermittent or "batch" furnace, meaning parts are loaded, remain stationary during the entire thermal cycle, and are then unloaded.

How It Achieves Uniform Heating

The furnace chamber uses a combination of radiation and convection to transfer heat. At lower temperatures, hot gas movement (convection) plays a role, but as the temperature rises, thermal radiation from the heating elements and internal furnace walls becomes the dominant, highly efficient method of heat transfer. This ensures the workpiece is heated evenly from all sides.

The Importance of Batch Processing

The design of a box furnace—typically with a single door for loading and unloading—makes it ideal for treating individual parts, small production runs, or materials that require long, uninterrupted soaking times. It offers flexibility that a continuous furnace, designed for high-volume production lines, cannot.

Common Heat Treatment Processes Explained

Each process is a unique recipe of temperature and time, designed to achieve a specific outcome in the material's properties.

Annealing: To Soften and Relieve Stress

Annealing involves heating a metal to a specific temperature, holding it there, and then cooling it very slowly. The primary goal is to soften the material, making it easier to machine or form. This process also refines the grain structure and relieves internal stresses that may have built up during previous manufacturing steps.

Hardening: Quenching & Tempering

Hardening is typically a two-step process used on steels to dramatically increase strength and wear resistance.

- Quenching: The steel is heated to a high temperature to transform its internal structure and then cooled rapidly by plunging it into a medium like water, oil, or air. This "freezes" a very hard but brittle microstructure in place.

- Tempering: The quenched, brittle part is then reheated to a much lower temperature. This secondary step relieves some of the internal stress and reduces brittleness, resulting in a final product that is both hard and tough.

Solution Treatment: For Specialized Alloys

Primarily used for non-ferrous alloys like aluminum, nickel, and stainless steels, solution treatment involves heating the material to dissolve alloying elements into a uniform solid solution. This is followed by rapid cooling to lock those elements in place, preparing the material for subsequent aging or precipitation hardening processes.

Advanced & Specialized Processes

Beyond the basics, box furnaces—especially those with controlled atmospheres—unlock further capabilities.

Sintering: Fusing Powders into Solids

Sintering is the process of taking compacted metal or ceramic powder and heating it to just below its melting point. The heat causes the particles to bond and fuse, creating a solid, dense component. This is fundamental to powder metallurgy.

Brazing: Creating Strong, Clean Joints

Brazing uses a filler metal with a lower melting point to join two pieces of a base metal. When performed in a vacuum or inert atmosphere box furnace, it produces exceptionally strong and clean joints without the need for flux, preventing oxidation and ensuring high integrity.

Carburizing: Hardening the Surface

Carburizing is a surface-hardening process where a steel part is heated in a carbon-rich atmosphere. Carbon diffuses into the surface of the part, creating a very hard, wear-resistant outer "case" while leaving the inner "core" tough and ductile.

Understanding the Trade-offs

While versatile, a box furnace is not the universal solution. Understanding its limitations is key to using it effectively.

Batch Processing vs. Continuous Flow

The greatest strength of a box furnace is also its main limitation. It is designed for batch work. It is inefficient for high-volume, standardized parts that would be better served by a continuous belt or pusher furnace integrated into a production line.

The Critical Role of Atmosphere

A simple box furnace heats parts in ambient air, which is acceptable for many basic steel treatments. However, oxygen in the air will cause scaling and oxidation at high temperatures. For processes like brazing, sintering, or treating reactive metals, a specialized furnace that can hold an inert gas atmosphere or a vacuum is essential to protect the part's surface.

Cycle Time and Energy Use

Heating a large, well-insulated furnace chamber and the material inside takes time and energy. The same is true for cooling. The total cycle time for a single batch can be many hours, which must be factored into production planning.

Making the Right Choice for Your Goal

To select the right process, you must first define your objective for the material.

- If your primary focus is improving machinability and reducing stress: Annealing is the correct process to soften the material and make it more ductile.

- If your primary focus is maximizing hardness and wear resistance: A two-step hardening process (quenching and tempering) or a surface treatment like carburizing is your goal.

- If your primary focus is joining complex parts or creating parts from powder: Brazing or sintering, likely requiring a controlled atmosphere or vacuum furnace, is the necessary path.

- If your primary focus is optimizing the properties of aluminum or stainless steel alloys: Solution treatment is the specific process designed for these materials.

Ultimately, the box furnace serves as a powerful instrument for precise and repeatable material engineering.

Summary Table:

| Process | Primary Goal | Key Applications |

|---|---|---|

| Annealing | Soften material, relieve stress | Improving machinability, reducing internal stress |

| Hardening | Increase hardness and wear resistance | Strengthening steels via quenching and tempering |

| Tempering | Reduce brittleness, improve toughness | Balancing hardness with durability in hardened parts |

| Solution Treatment | Dissolve alloying elements uniformly | Optimizing properties in aluminum and stainless steel alloys |

| Sintering | Fuse powders into solid components | Powder metallurgy for dense parts |

| Brazing | Create strong, clean joints | Joining metals without oxidation in controlled atmospheres |

| Carburizing | Harden surface layer | Enhancing wear resistance in steels with a tough core |

Unlock the full potential of your heat treatment processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're working with metals, alloys, or ceramics, our furnaces ensure precise thermal control for processes like annealing, hardening, and sintering. Contact us today to discuss how we can enhance your lab's efficiency and achieve superior material outcomes!

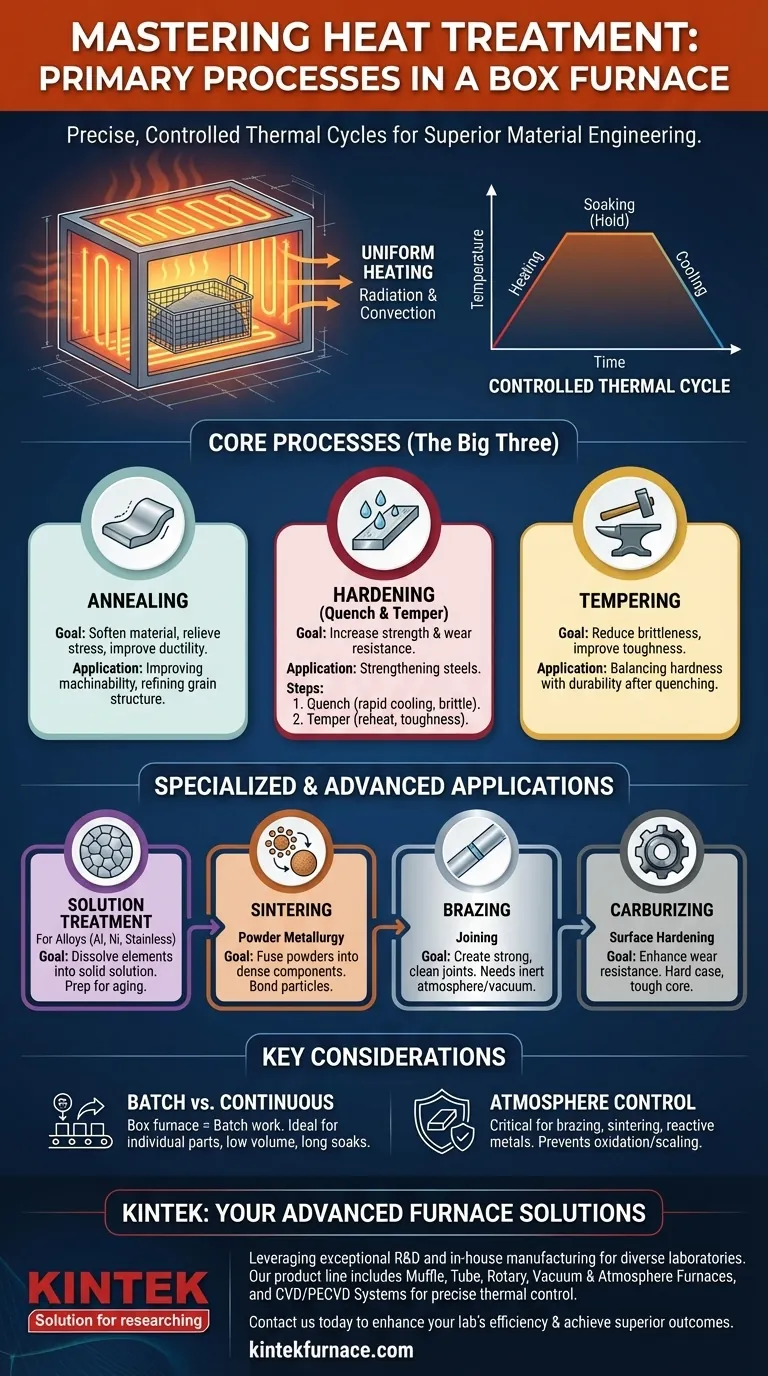

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification