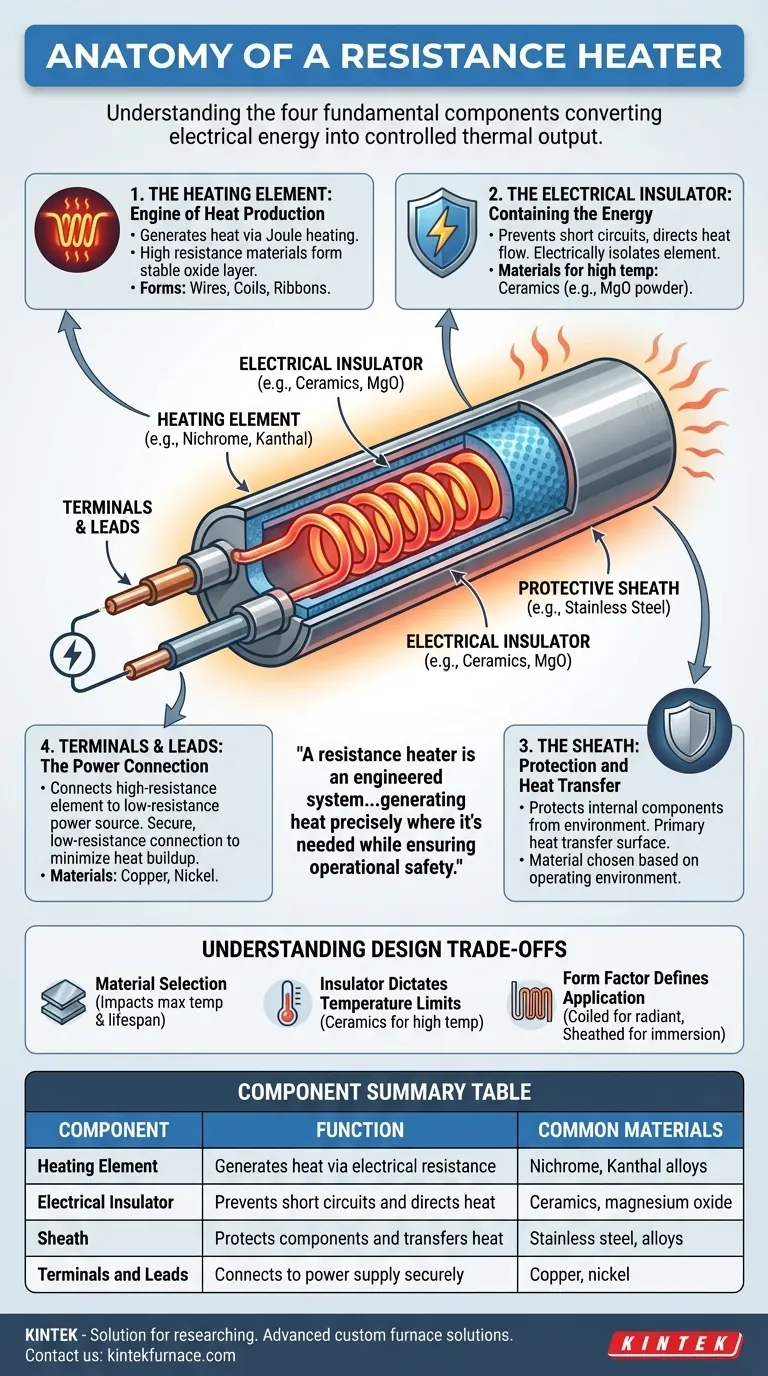

At its core, a resistance heater consists of four fundamental components. These are the heating element that generates heat, an electrical insulator to contain the energy safely, a protective outer sheath or casing, and the terminals and leads that connect the device to a power source. Each part is engineered to work in concert, turning electrical energy into controlled thermal output.

A resistance heater is not simply a "hot wire." It is an engineered system where the heating element, insulator, and termination work together to generate heat precisely where it's needed while preventing electrical faults and ensuring operational safety.

The Anatomy of a Resistance Heater

To understand how a resistance heater functions, we must examine the role of each primary component. The interaction between these parts defines the heater's performance, safety, and suitability for a given application.

The Heating Element: The Engine of Heat Production

The heating element is the active component responsible for generating heat. It is made from a material with high electrical resistance, such as a Nichrome (nickel-chromium) or Kanthal (iron-chromium-aluminum) alloy.

When an electric current passes through this material, resistance causes the electrical energy to be converted into heat—a principle known as Joule heating.

These elements come in various forms, including wires, coils, or flat ribbons, depending on the heat distribution requirements. Materials like Nichrome are favored because they form a stable, protective layer of chromium oxide on their surface at high temperatures, which prevents further oxidation and extends the element's lifespan.

The Electrical Insulator: Containing the Energy

The insulator serves two critical functions: it prevents electrical short circuits and helps direct the flow of heat. It electrically isolates the high-voltage heating element from the outer casing and surrounding environment.

For temperatures above 600°C (1112°F), ceramics are the standard insulating material due to their excellent thermal stability and high dielectric strength. In components like tubular heaters, this insulator often takes the form of a compressed powder (like magnesium oxide) that fills the space around the heating coil.

The Sheath: Protection and Heat Transfer

Many resistance heaters, particularly tubular or cartridge types, are enclosed in a metallic sheath. This outer casing protects the internal components from moisture, contamination, and physical damage.

The sheath material (often stainless steel or other alloys) is chosen based on the operating environment. It also provides the primary surface for transferring heat to the surrounding medium, whether it's air, a liquid, or a solid surface.

The Terminals and Leads: The Power Connection

The terminals are a critical junction, connecting the high-resistance heating element to the low-resistance lead wires that run to the power supply. This design is intentional.

You want heat generated in the element, not in the connection wiring. The terminals are engineered to create a secure, low-resistance connection that minimizes heat buildup at the point of entry, which is a common failure point in poorly designed heaters. The leads themselves are typically made of highly conductive materials like copper or nickel.

Understanding the Design Trade-offs

The construction of a resistance heater is a series of deliberate engineering choices. The materials and form factor are selected to balance performance, cost, and durability for a specific task.

Material Selection is Critical

The choice of heating element alloy directly impacts the heater's maximum operating temperature and lifespan. Nichrome is a versatile workhorse, while Kanthal alloys can often reach even higher temperatures, making them suitable for industrial furnaces.

The Insulator Dictates Temperature Limits

The insulating material is often the limiting factor for a heater's maximum temperature rating. While ceramics excel at high temperatures, other insulators may be used for lower-temperature applications to reduce cost or improve flexibility.

Form Factor Defines the Application

The physical shape of a heater is not arbitrary. A coiled wire is ideal for radiant heating in open air (like a toaster), while a sheathed tubular element is perfect for immersion in liquids or insertion into drilled holes. These tubes can be bent into complex shapes to fit specific machinery or optimize heat distribution.

Applying This to Your Goal

The optimal heater design depends entirely on your objective. Understanding these components helps you select or specify the right tool for the job.

- If your primary focus is high-temperature industrial processes: You need a heater with a Kanthal or robust Nichrome element, high-purity ceramic insulation, and a durable alloy sheath.

- If your primary focus is a consumer appliance: Cost-effectiveness and reliability are key, making a simple Nichrome wire or ribbon element a common and effective choice.

- If your primary focus is heating liquids or fitting into specific geometry: A sheathed tubular heater offers the best protection and can be custom-formed for your application.

By understanding how each component contributes to the whole, you can more effectively design, troubleshoot, and specify heating systems for any task.

Summary Table:

| Component | Function | Common Materials |

|---|---|---|

| Heating Element | Generates heat via electrical resistance | Nichrome, Kanthal alloys |

| Electrical Insulator | Prevents short circuits and directs heat | Ceramics, magnesium oxide |

| Sheath | Protects components and transfers heat | Stainless steel, alloys |

| Terminals and Leads | Connects to power supply securely | Copper, nickel |

Need a custom high-temperature furnace solution for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced heaters, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise performance for your unique experimental needs. Contact us today to enhance your heating efficiency and safety!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs

- What are the primary applications of Molybdenum Disilicide (MoSi2) heating elements in furnaces? Achieve High-Temp Excellence

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure