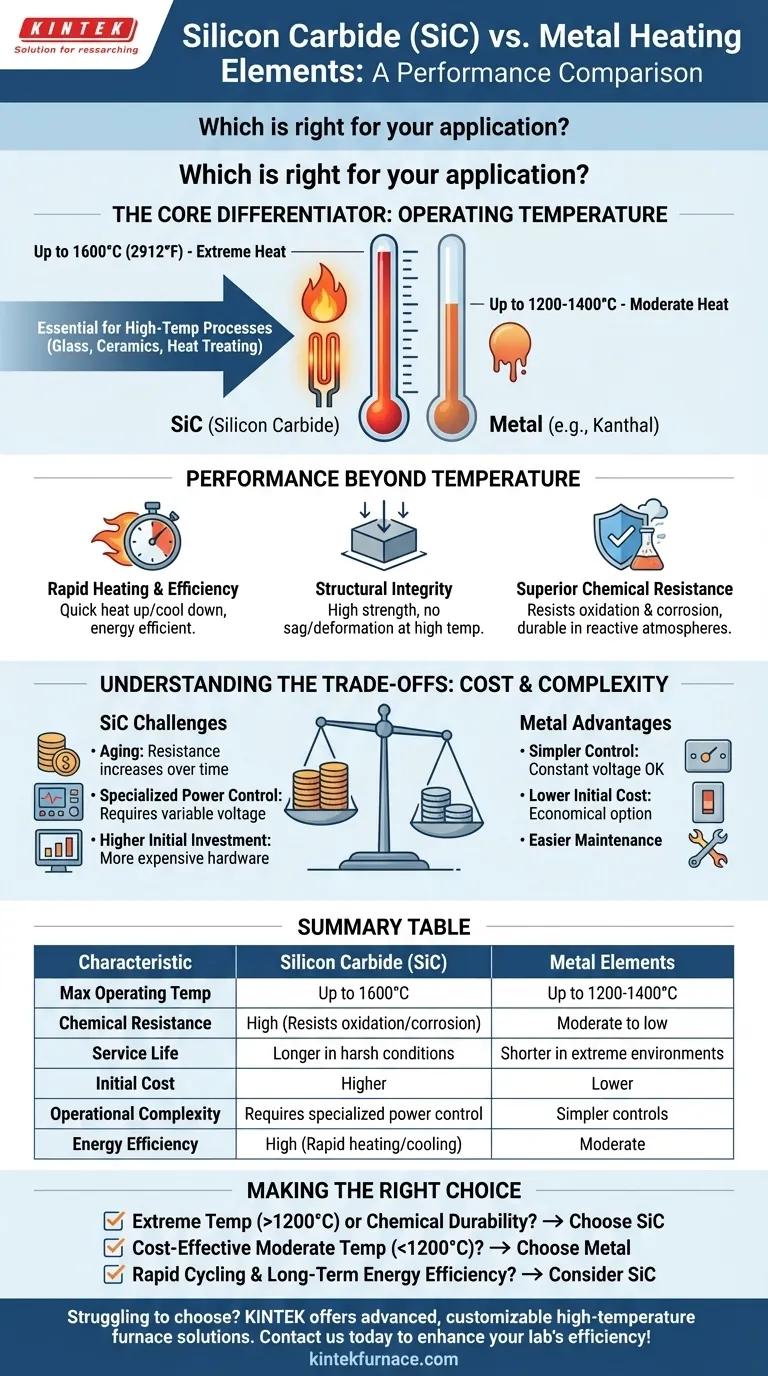

When selecting a heating element, the choice between silicon carbide (SiC) and traditional metal is a critical engineering decision. Silicon carbide elements operate at significantly higher temperatures, offer superior chemical resistance, and provide a longer service life in harsh conditions. However, this high performance comes with a higher initial cost and greater operational complexity compared to their metallic counterparts.

The decision is not about which element is universally "better," but which is appropriate for the specific thermal and financial constraints of your application. SiC excels in extreme environments where metal cannot survive, while metal remains the cost-effective standard for moderate-temperature processes.

The Core Differentiator: Operating Temperature

The most significant distinction between SiC and metal heating elements is their maximum service temperature. This single factor often dictates which material is viable for a given process.

Silicon Carbide's High-Temperature Capability

SiC elements are engineered for extreme heat. They can operate consistently at temperatures up to 1600°C (2912°F), making them essential for applications like glass melting, metal heat treating, and firing technical ceramics.

The Limits of Metal Elements

Traditional metallic heating elements, such as those made from iron-chromium-aluminum alloys (e.g., Kanthal), have a much lower operating ceiling. While robust, they typically begin to fail as temperatures approach and exceed 1200°C - 1400°C, rendering them unsuitable for the most demanding high-temperature industrial processes.

Performance Beyond Temperature

Beyond simple heat tolerance, the materials behave differently in terms of efficiency, structural integrity, and chemical stability. These factors directly impact operational performance and lifetime costs.

Rapid Heating and Energy Efficiency

SiC possesses excellent thermal conductivity, allowing elements to heat up and cool down very quickly. This responsiveness is ideal for processes that require rapid thermal cycling and helps improve overall energy efficiency, reducing operational costs over time.

Structural Integrity Under Load

At elevated temperatures where metals may sag or deform, SiC maintains its high strength and physical form. This structural rigidity ensures uniform heating within a furnace and contributes to a longer, more predictable service life.

Superior Chemical Resistance

SiC is highly resistant to both oxidation and general corrosion. This makes it a durable choice for use in furnaces with reactive atmospheres, where metallic elements would quickly degrade and fail.

Understanding the Trade-offs: Cost and Complexity

The superior performance of silicon carbide comes with significant trade-offs that are critical to understand before making an investment. It is not a simple drop-in replacement for metal.

The Challenge of "Aging"

The most important characteristic to manage in SiC elements is aging. Over its service life, a SiC element's electrical resistance gradually increases. This is a natural, unavoidable phenomenon for this material.

The Need for Specialized Power Control

Because the resistance increases with age, a constant voltage would deliver progressively less power (and thus less heat). To compensate, SiC systems require specialized power controllers, such as multi-tap transformers or Silicon Controlled Rectifiers (SCRs), that can increase the voltage over time to maintain a constant power output.

Higher Initial Investment

Silicon carbide elements and their required power control systems are significantly more expensive than traditional metallic elements and their simpler controls. The initial capital outlay is a primary consideration in the selection process.

The Nuance of Maintenance

While physically installing SiC elements can be straightforward, the "maintenance" involves managing their electrical properties. This often includes periodically adjusting transformer taps or planning for group replacement of elements to maintain thermal uniformity in the furnace, a layer of complexity not present with most metal elements.

Making the Right Choice for Your Application

Your decision should be guided by the non-negotiable requirements of your process.

- If your primary focus is extreme temperature (above 1200°C) or chemical durability: Silicon carbide is the necessary and correct choice, as metallic elements are not viable in this range.

- If your primary focus is cost-effectiveness for moderate temperatures (below 1200°C): Traditional metallic elements provide a highly reliable and economical solution without the complexity of SiC systems.

- If your primary focus is rapid cycling and long-term energy efficiency: The thermal properties and durability of SiC may provide a lower total cost of ownership that justifies the higher initial investment.

By balancing thermal requirements against budgetary and operational realities, you can confidently select the heating technology that best aligns with your goals.

Summary Table:

| Characteristic | Silicon Carbide (SiC) | Metal Elements |

|---|---|---|

| Max Operating Temperature | Up to 1600°C | Up to 1200-1400°C |

| Chemical Resistance | High (resists oxidation and corrosion) | Moderate to low |

| Service Life | Longer in harsh conditions | Shorter in extreme environments |

| Initial Cost | Higher | Lower |

| Operational Complexity | Requires specialized power control | Simpler controls |

| Energy Efficiency | High due to rapid heating/cooling | Moderate |

Struggling to choose the right heating element for your high-temperature processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs precisely. Contact us today to discuss how our high-temperature furnace solutions can enhance your lab's efficiency and performance!

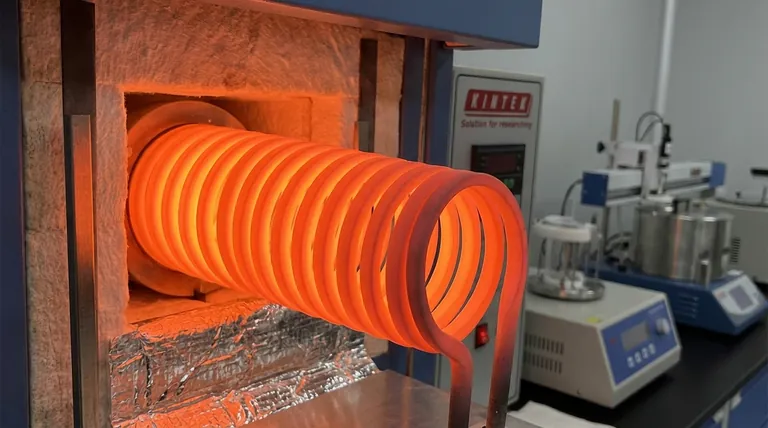

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions