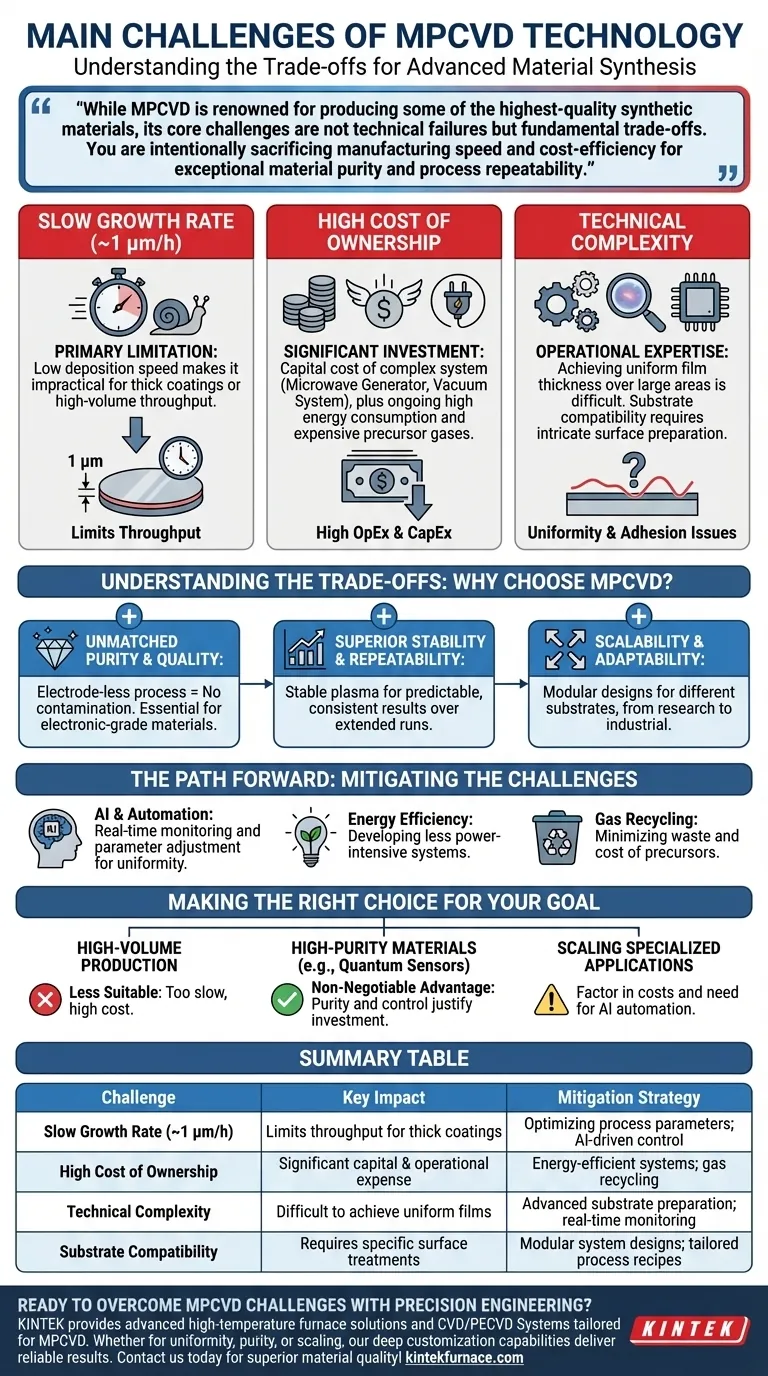

The primary challenges of Microwave Plasma Chemical Vapor Deposition (MPCVD) center on its slow growth rate, significant operational costs, and the technical complexity required to achieve uniform, high-quality films. These factors create a barrier to entry and limit its use to applications where its unique benefits—namely purity and control—outweigh the drawbacks in speed and expense.

While MPCVD is renowned for producing some of the highest-quality synthetic materials, its core challenges are not technical failures but fundamental trade-offs. You are intentionally sacrificing manufacturing speed and cost-efficiency for exceptional material purity and process repeatability.

Deconstructing the Core Challenges

To properly evaluate MPCVD, you must understand the practical implications of each of its main hurdles. These challenges are interconnected, stemming from the sophisticated physics and equipment required for the process.

The Growth Rate Dilemma

The most cited limitation of MPCVD is its slow deposition rate, which is often around 1 micrometer per hour (μm/h).

While sufficient for thin films, this rate is significantly slower than other Chemical Vapor Deposition (CVD) methods. This makes MPCVD impractical for applications requiring thick coatings or high-volume throughput.

High Cost of Ownership

The financial investment for MPCVD is substantial and extends beyond the initial purchase.

Key cost drivers include the high price of the system itself, which contains complex components like a microwave generator and a high-grade vacuum system. Ongoing expenses include significant energy consumption, costly precursor gases, and regular maintenance by skilled technicians.

Operational and Technical Complexity

Operating an MPCVD system is not a plug-and-play process. It demands a high level of expertise to manage its sensitive parameters.

A major operational hurdle is achieving uniform film thickness, especially over large-area substrates. Furthermore, substrate compatibility is a persistent issue, often requiring intricate and material-specific surface preparation to ensure proper film adhesion and growth.

Understanding the Trade-offs: Why Choose MPCVD?

Despite these significant challenges, MPCVD remains a dominant technology in high-stakes fields. The reason is that its disadvantages are the flip side of its greatest strengths.

Unmatched Purity and Quality

MPCVD is an electrode-less process. The plasma is generated by microwaves, meaning there are no internal electrodes that can degrade and contaminate the film.

This single feature is critical for producing exceptionally high-purity materials, such as electronic-grade diamond or graphene, where even trace impurities can ruin device performance.

Superior Stability and Repeatability

The technology is known for its stable and reproducible deposition process. Once a process is dialed in, an MPCVD system can run for extended periods, producing consistent results from batch to batch.

This reliability is non-negotiable for scientific research and industrial manufacturing, where predictable outcomes are essential.

Scalability and Adaptability

Modern MPCVD systems feature a modular and scalable design. This allows them to be adapted for different substrate sizes and configurations, moving a process from a research lab to a specialized industrial production line.

The Path Forward: Mitigating the Challenges

The industry is actively working to address MPCVD's limitations through technological advancements, making the process more accessible and efficient.

Tackling Uniformity with AI

To solve the problem of film uniformity over large areas, new systems are integrating automation and Artificial Intelligence (AI). These smart systems can monitor the deposition in real-time and adjust process parameters to ensure a consistent coating.

Addressing Throughput and Cost

Research is focused on developing more energy-efficient microwave systems to reduce operational costs. Concurrently, efforts are underway to identify alternative, less expensive precursor gases and implement gas recycling systems to minimize waste and expense.

Making the Right Choice for Your Goal

The decision to use MPCVD must be based on a clear understanding of your project's primary objective.

- If your primary focus is high-volume production or general-purpose coatings: MPCVD's slow growth rate and high cost make it a less suitable choice compared to faster, more economical deposition techniques.

- If your primary focus is cutting-edge research or fabricating high-purity materials (e.g., electronic-grade diamond, quantum sensors): MPCVD's superior control, purity, and repeatability are non-negotiable advantages that justify the investment and complexity.

- If your primary focus is scaling a specialized application to an industrial level: You must factor in high capital costs and the need for process automation (like AI control) to overcome uniformity and repeatability challenges on larger substrates.

Understanding this balance between precision and practicality is the key to leveraging MPCVD technology effectively.

Summary Table:

| Challenge | Key Impact | Mitigation Strategy |

|---|---|---|

| Slow Growth Rate (~1 μm/h) | Limits throughput for thick coatings | Optimizing process parameters; AI-driven control |

| High Cost of Ownership | Significant capital & operational expense | Energy-efficient systems; gas recycling |

| Technical Complexity | Difficult to achieve uniform films | Advanced substrate preparation; real-time monitoring |

| Substrate Compatibility | Requires specific surface treatments | Modular system designs; tailored process recipes |

Ready to Overcome MPCVD Challenges with Precision Engineering?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions tailored for demanding applications like MPCVD. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're tackling uniformity issues, scaling up processes, or optimizing for purity, we deliver reliable, repeatable results.

Contact us today (#ContactForm) to discuss how our expertise can help you achieve superior material quality and process efficiency!

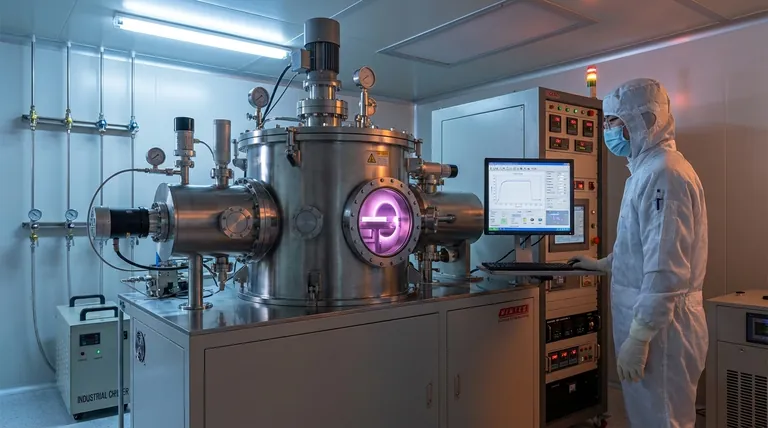

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth

- What are the operational benefits of using a CVD Tube Furnace? Enhance Precision and Efficiency in Your Lab

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision