In short, the latest technological advancements in zirconia sintering furnaces revolve around achieving faster cycles, greater precision, and higher operational efficiency through intelligent automation. Modern furnaces now combine programmable heating, superior heating elements, and user-friendly controls to deliver more consistent results in a fraction of the time required by older models.

The core evolution is a shift from a slow, manually-monitored process to a fast, automated, and highly reliable workflow. This change is not merely about new features; it's about fundamentally improving a dental lab's productivity, profitability, and the quality of its final restorations.

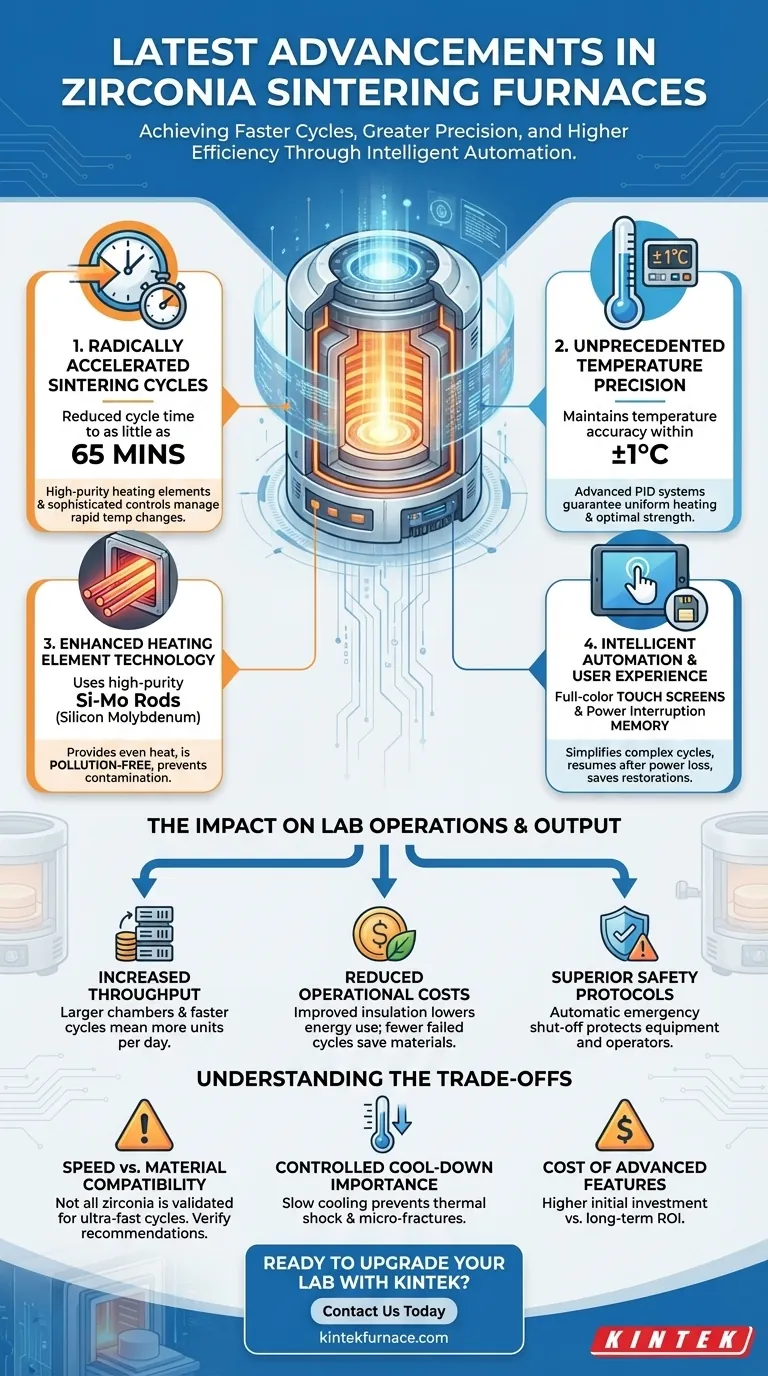

The Core Advancements Driving Modern Furnaces

Today's furnaces are defined by a convergence of technologies that address the historical challenges of zirconia sintering: long wait times, inconsistent results, and high energy consumption.

Radically Accelerated Sintering Cycles

The most significant advancement is the dramatic reduction in cycle time. Some modern furnaces can now complete a full sintering program in as little as 65 minutes, a stark contrast to the multi-hour processes of the past.

This speed is made possible by a combination of high-purity heating elements and sophisticated control systems that manage rapid temperature changes without compromising the material's integrity.

Unprecedented Temperature Precision

To ensure consistent results and prevent defects like warping or poor translucency, precise temperature control is paramount.

New furnaces utilize advanced Proportional-Integral-Derivative (PID) control systems to maintain temperature accuracy, often within ±1℃. This level of precision guarantees that the entire restoration heats and cools uniformly, which is critical for achieving optimal strength and aesthetics.

Enhanced Heating Element Technology

The quality of the heating element directly impacts the final product. The latest models often use high-purity silicon molybdenum (Si-Mo) rods.

These advanced elements provide exceptionally even heat distribution and, crucially, are pollution-free. This prevents contamination of the zirconia, which can cause discoloration and compromise the final aesthetic outcome.

Intelligent Automation and User Experience

Manual programming and monitoring are being replaced by intuitive, automated systems. Features like large, full-color touch screens simplify the programming of complex, multi-stage cycles.

Furthermore, a power interruption memory function is becoming standard. If power is lost, the furnace can resume the cycle exactly where it left off, saving the restoration and preventing costly waste.

The Impact on Lab Operations and Output

These technological leaps translate directly into tangible benefits for the dental lab, research facility, or manufacturing center.

Increased Throughput and Productivity

Faster cycles combined with larger furnace chambers mean a lab can process significantly more units in a single day. This directly increases a lab's production capacity and revenue potential.

Reduced Operational Costs

Modern furnaces are designed for efficiency. Improved green thermal insulation materials reduce heat loss, lowering energy consumption per cycle.

Precise control and automation also minimize the risk of failed sintering cycles, which saves on both material waste and the labor cost of remaking a case.

Superior Safety Protocols

Safety is a primary concern when operating equipment at temperatures up to 1600°C. New furnaces feature robust, automated safety mechanisms.

These include automatic emergency shut-off functions that trigger if the furnace detects an over-temperature or other system failure, protecting both the equipment and the operator.

Understanding the Trade-offs

While the advancements are significant, it's critical to approach them with a clear understanding of the associated considerations.

Speed vs. Material Compatibility

Not all zirconia materials are validated for ultra-fast sintering cycles. Using a material in a cycle for which it has not been approved by the manufacturer can result in reduced strength, poor marginal fit, or compromised aesthetics. Always verify the recommended cycle for your specific zirconia puck.

The Importance of a Controlled Cool-Down

Even with rapid heating, the slow cooling phase is non-negotiable for preventing thermal shock, which can cause micro-fractures in the restoration. The best fast-cycle furnaces are engineered to accelerate the heating and soaking phases while still ensuring a gradual, controlled cool-down.

Cost of Advanced Features

Furnaces equipped with the latest technology command a higher initial investment. A lab must perform a cost-benefit analysis, weighing the upfront purchase price against the long-term return on investment from increased productivity, lower energy bills, and reduced material waste.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on your primary operational objectives.

- If your primary focus is maximum throughput: Prioritize furnaces with the fastest validated sintering cycles and the largest chamber capacity to meet high-volume demands.

- If your primary focus is the highest aesthetic quality: Seek furnaces with superior temperature uniformity (±1℃) and highly programmable cycles that allow for slower, more customized profiles for complex anterior cases.

- If your primary focus is reliability and cost-effectiveness: Emphasize features like power interruption recovery, energy-efficient insulation, and robust safety mechanisms to minimize downtime and operational expenses.

Ultimately, these advancements empower you with an unprecedented level of control over the sintering process, enabling more predictable, profitable, and high-quality results.

Summary Table:

| Advancement | Key Features | Benefits |

|---|---|---|

| Accelerated Sintering Cycles | High-purity heating elements, rapid temperature changes | Reduces cycle time to as little as 65 minutes, increases throughput |

| Temperature Precision | PID control systems, accuracy within ±1℃ | Ensures uniform heating, prevents defects, improves strength and aesthetics |

| Heating Element Technology | Silicon molybdenum (Si-Mo) rods, pollution-free | Provides even heat distribution, prevents zirconia contamination |

| Intelligent Automation | Full-color touch screens, power interruption memory | Simplifies programming, saves restorations, reduces waste |

| Operational Efficiency | Larger chambers, improved insulation | Lowers energy costs, enhances safety with automatic shut-off |

Ready to upgrade your lab with the latest zirconia sintering technology? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental labs, research facilities, and manufacturing centers. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Boost your productivity, reduce costs, and achieve superior results—contact us today to learn how our furnaces can transform your operations!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique