The key steps in the dental zirconia sintering process involve a multi-stage, highly controlled heating and cooling cycle inside a specialized furnace. After a milled zirconia restoration is placed in the furnace, the temperature is gradually increased to a specific peak (typically 1350-1550°C), held at that temperature for a "dwell" period to allow for full densification, and then slowly cooled to prevent thermal shock and cracking. This transforms the soft, chalk-like pre-sintered material into a hard, dense, and esthetic final ceramic restoration.

Sintering is not simply a heating process; it is a precise material transformation. Achieving a successful outcome hinges on meticulously following a time-temperature protocol specific to the zirconia material, as this control dictates the final restoration's strength, translucency, and longevity.

The Purpose of Sintering: From Chalk to Ceramic

The entire goal of digital dental workflows using zirconia is to create strong, lifelike restorations. This cannot be achieved without the critical step of sintering.

Why Zirconia is Milled in a 'Soft' State

Zirconia restorations are initially milled from a pre-sintered or "green state" block. In this form, the material is soft, porous, and chalk-like.

This softness is intentional. It allows dental CAD/CAM milling units to shape the crown or bridge with minimal stress on the machine and milling burs, enabling high precision and intricate detail.

The Transformation Process

Sintering is the thermal process that transforms this soft, porous shape into a dense, non-porous ceramic.

During the cycle, the individual zirconia particles fuse together, eliminating the voids between them. This causes the restoration to shrink by a predictable amount (typically 20-25%), which is accounted for in the initial design software. The process dramatically increases the material's density, flexural strength, and fracture toughness.

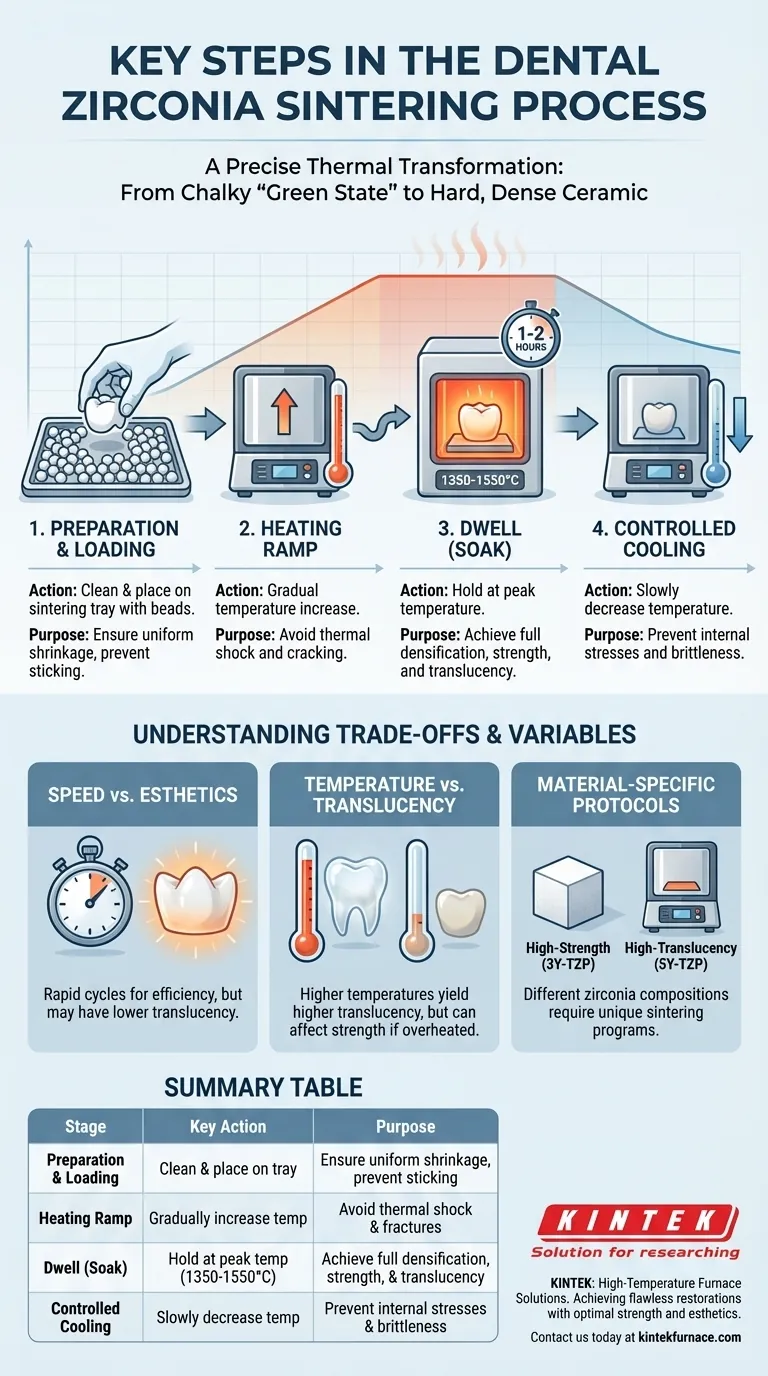

A Step-by-Step Breakdown of the Sintering Cycle

While furnaces and materials vary, the fundamental stages of a conventional sintering cycle remain consistent. Deviating from this controlled process is the primary cause of failures like cracks or poor esthetics.

Stage 1: Preparation and Loading

Before the cycle begins, the milled restoration must be carefully cleaned of all dust and debris with a soft brush. It is then placed on a sintering tray, often with zirconia beads, to allow for uniform shrinkage and to prevent it from sticking to the tray.

Stage 2: The Heating Ramp

The furnace does not immediately jump to its peak temperature. Instead, it follows a gradual heating ramp. This slow increase in temperature is critical to prevent thermal shock, which could cause fractures in the material before it ever reaches full density.

Stage 3: The Dwell (or Soak)

Once the furnace reaches its target temperature (e.g., 1530°C), it holds that temperature for a specific period, known as the dwell time. This phase, often lasting one to two hours, is when the majority of densification occurs. The particles fuse, and the restoration achieves its final strength and translucency.

Stage 4: The Controlled Cooling

Just as important as the heating ramp is the controlled cooling phase. The furnace slowly lowers the temperature at a managed rate. Opening the furnace too early or cooling the restoration too quickly will induce internal stresses, making it brittle and highly susceptible to fractures.

Understanding the Trade-offs and Variables

The "perfect" sintering cycle is not one-size-fits-all. It involves balancing three critical factors: time, temperature, and the desired final properties of the restoration.

Speed vs. Esthetics

Many modern furnaces offer "speed" or "fast" sintering cycles that can be completed in a fraction of the time of a conventional cycle. While excellent for lab efficiency, these rapid cycles can sometimes result in lower translucency compared to a traditional, slower firing.

Temperature vs. Translucency

The peak sintering temperature directly influences the final esthetics. Generally, higher temperatures yield higher translucency. However, overheating the material can lead to larger grain growth, which may slightly decrease the flexural strength. This is why following the manufacturer's validated temperature for a specific zirconia type is non-negotiable.

Material-Specific Protocols

Different types of zirconia (e.g., high-strength 3Y-TZP for posteriors vs. high-translucency 5Y-TZP for anteriors) have different chemical compositions and require unique sintering protocols. Using a program designed for one type of zirconia on another will result in a compromised or failed restoration.

Making the Right Choice for Your Goal

Selecting a sintering protocol requires matching the program to the clinical and business needs of the case.

- If your primary focus is maximum strength: Use a conventional (slower) sintering cycle and adhere to the manufacturer's recommended temperature for that high-strength material.

- If your primary focus is high esthetics for an anterior tooth: Select a high-translucency zirconia and use the specific sintering program designed to optimize its optical properties, which may involve a higher peak temperature.

- If your primary focus is rapid turnaround for a single unit: A validated speed sintering cycle is a viable option, but ensure both your furnace and zirconia material are specifically approved for this process.

Ultimately, mastering the sintering process is about exercising precise control to reliably transform a simple milled shape into a durable and beautiful restoration.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| Preparation and Loading | Clean and place restoration on tray | Ensure uniform shrinkage and prevent sticking |

| Heating Ramp | Gradually increase temperature | Avoid thermal shock and fractures |

| Dwell (Soak) | Hold at peak temperature (1350-1550°C) | Achieve full densification, strength, and translucency |

| Controlled Cooling | Slowly decrease temperature | Prevent internal stresses and brittleness |

Ready to enhance your dental lab's precision and efficiency? KINTEK specializes in high-temperature furnace solutions tailored for dental zirconia sintering. Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by deep customization, ensure you achieve flawless restorations with optimal strength and esthetics. Contact us today to discuss how our advanced technology can meet your unique needs!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision