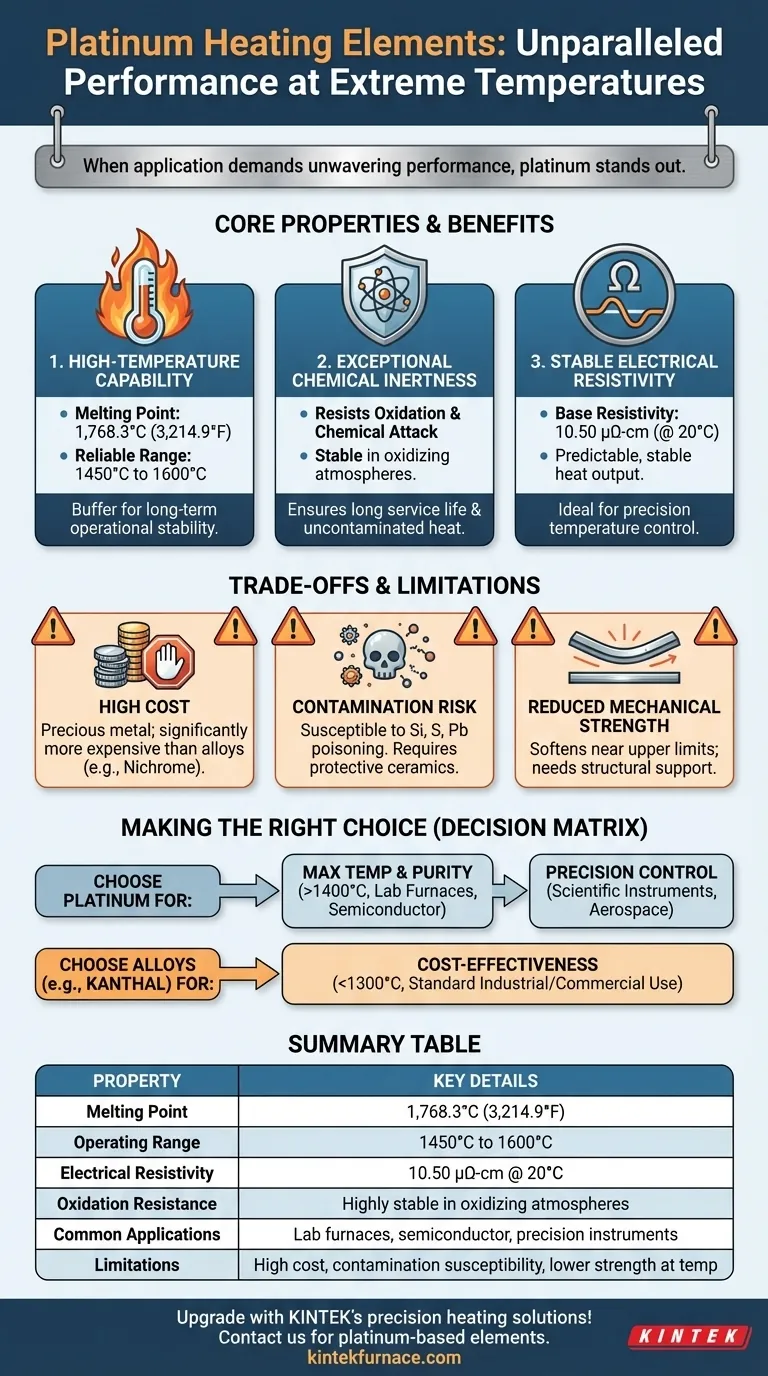

When your application demands unwavering performance at extreme temperatures, platinum stands out as a premier material for heating elements. Its suitability is defined by a unique combination of a very high melting point, exceptional resistance to oxidation and chemical attack, and highly stable electrical properties over a vast temperature range. This makes it a critical component in environments where reliability is paramount.

The true value of platinum isn't merely its ability to withstand high heat, but its predictable and stable behavior while doing so. This combination of high-temperature capability and long-term resistance stability makes it the definitive choice for applications where precision and reliability are non-negotiable.

The Core Properties of Platinum Heaters

Platinum's performance as a heating element is not based on a single attribute, but on the interplay of several key physical and chemical properties. Understanding these is crucial to its proper application.

High-Temperature Capability

Platinum has a very high melting point of 1,768.3°C (3,214.9°F). This fundamental property allows it to operate reliably at temperatures where many other metals would fail.

For standard heating element use, platinum is typically employed in a temperature range of 1450°C to 1600°C, providing a significant buffer below its melting point for long-term operational stability.

Exceptional Chemical Inertness

One of platinum's most significant advantages is its resistance to oxidation. At extreme temperatures, most metals react with oxygen in the air, forming oxide layers that degrade performance and lead to eventual failure.

Platinum remains remarkably stable and inert in oxidizing atmospheres, which ensures a much longer service life and consistent heating performance over time. This property is vital for furnaces and processes requiring clean, uncontaminated heat.

Stable Electrical Resistivity

Platinum has a base electrical resistivity of 10.50 μΩ-cm (at 20°C). More importantly, the relationship between its resistance and temperature is extremely stable and well-documented.

This predictability means that the heat output of a platinum element remains consistent and controllable. It is this exact property that also makes platinum the standard for high-precision temperature sensors like thermocouples and resistance thermometers (RTDs).

Understanding the Trade-offs and Limitations

While platinum offers superior performance, its use involves practical and financial considerations that must be weighed against its benefits.

The Primary Factor: Cost

The most significant barrier to using platinum is its high cost as a precious metal. Its price is many times that of common resistance heating alloys like Nichrome (nickel-chromium) or Kanthal (iron-chromium-aluminum).

This cost restricts its use to applications where lower-cost alternatives cannot meet the required temperature, purity, or lifespan demands.

Susceptibility to Contamination

Despite its general inertness, platinum can be "poisoned" or degraded by contact with certain elements at high temperatures, particularly silicon, sulfur, and lead.

This requires careful furnace design to prevent contaminants from reaching the heating elements. Embedding the platinum elements within high-purity refractory ceramics is a common strategy to protect them and minimize material loss.

Mechanical Strength at Temperature

Like all metals, platinum softens as it approaches its upper operating limits. This reduction in mechanical strength means heating elements may require structural support to prevent sagging or deformation over long-term use, especially in larger furnace applications.

Making the Right Choice for Your Goal

Selecting the right heating element material is a critical engineering decision that balances performance requirements with budget constraints.

- If your primary focus is maximum temperature and process purity: Platinum is the superior choice for lab furnaces, semiconductor processing, and glass manufacturing where stability above 1400°C and a non-contaminating heat source are required.

- If your primary focus is precision temperature control: Platinum's stable resistance-temperature curve makes it unmatched for scientific instruments and aerospace components that demand predictable and repeatable thermal cycling.

- If your primary focus is cost-effectiveness below 1300°C: Other alloys like Kanthal or Nichrome offer excellent performance at a fraction of the cost and are the standard choice for the vast majority of industrial and commercial heating applications.

Ultimately, selecting platinum is an investment in unparalleled stability and longevity for your most critical high-temperature processes.

Summary Table:

| Property | Key Details |

|---|---|

| Melting Point | 1,768.3°C (3,214.9°F) |

| Operating Temperature Range | 1450°C to 1600°C |

| Electrical Resistivity | 10.50 μΩ-cm at 20°C |

| Oxidation Resistance | Highly stable in oxidizing atmospheres |

| Common Applications | Lab furnaces, semiconductor processing, precision instruments |

| Limitations | High cost, susceptibility to contamination, reduced mechanical strength at high temperatures |

Upgrade your high-temperature processes with KINTEK's precision heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for reliability and efficiency. Contact us today to discuss how our platinum-based heating elements can enhance your applications!

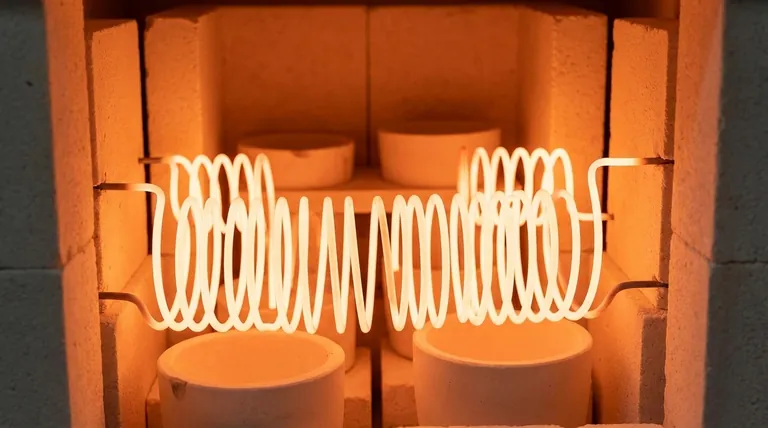

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key differences between SiC and MoSi2 heating elements in sintering furnaces? Choose the Right Element for Your High-Temp Needs

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs

- What are the primary applications of Molybdenum Disilicide (MoSi2) heating elements in furnaces? Achieve High-Temp Excellence