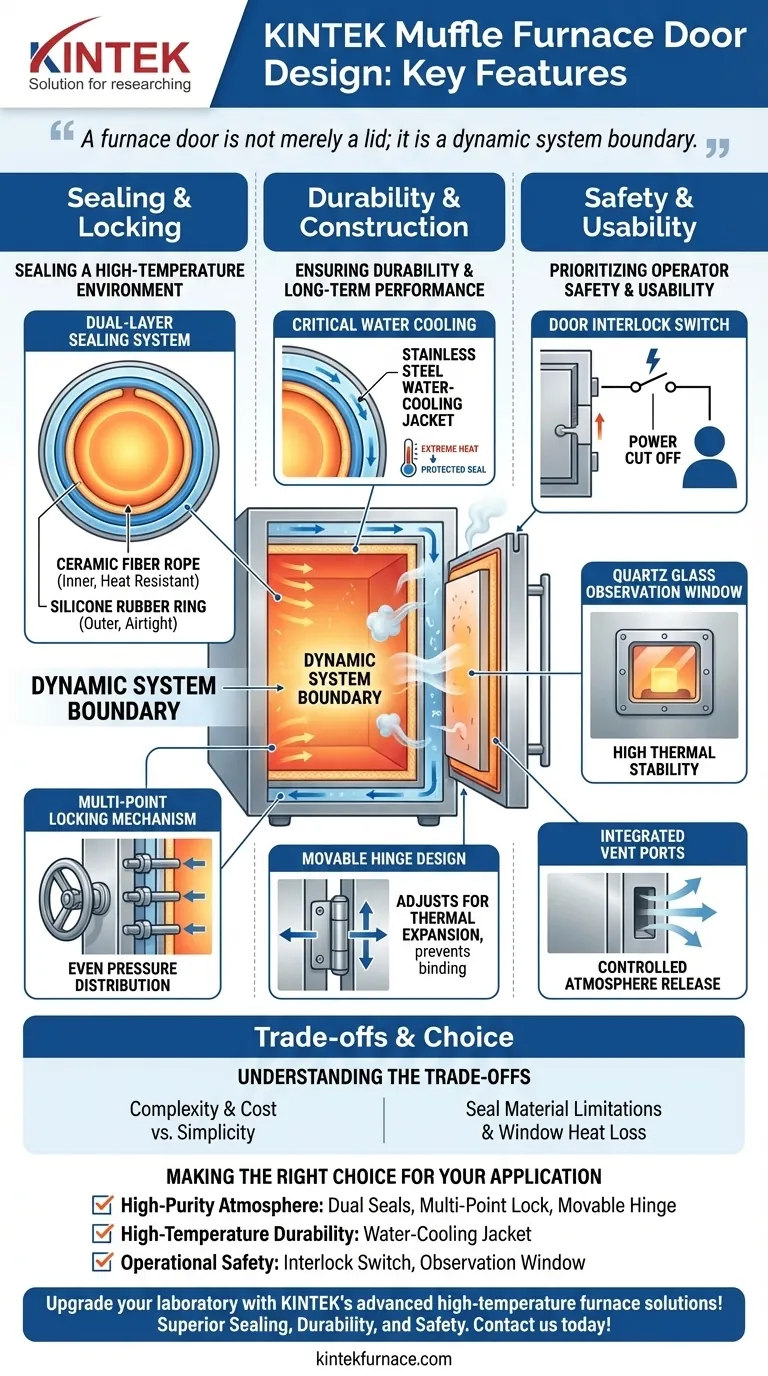

A muffle furnace door is engineered for much more than just access. Its key design features include a dual-layer sealing system, typically an inner ceramic fiber rope and an outer silicone rubber ring, protected by a stainless steel water-cooling jacket. This is complemented by a multi-point handwheel locking mechanism for even pressure and a movable double-hinge that adjusts for thermal expansion, ensuring a consistently tight seal.

A furnace door is not merely a lid; it is a dynamic system boundary. Its design features are a direct solution to three core challenges: maintaining a perfectly sealed internal atmosphere, ensuring long-term durability against extreme heat, and guaranteeing operator safety.

The Core Challenge: Sealing a High-Temperature Environment

A muffle furnace's performance depends on its ability to isolate the internal chamber. The door is the most vulnerable point for heat loss and atmospheric contamination.

The Dual-Layer Sealing System

The design uses two different materials to achieve a superior seal. The inner seal is typically a ceramic fiber rope, chosen for its extreme heat resistance directly facing the chamber.

The outer seal is often a silicone rubber ring. While less heat-resistant, it provides a more pliable and airtight seal against the furnace body, preventing gas leakage.

The Multi-Point Locking Mechanism

To ensure the seals are effective, the door must close with perfectly even pressure. A multi-point handwheel rotation mechanism accomplishes this.

As the user turns the handwheel, multiple locking points engage simultaneously around the door's perimeter. This distributes the closing force uniformly, compressing the seals without creating gaps.

The Movable Hinge Design

As a furnace heats up, its components expand. A rigid hinge would cause the door to bind or create gaps.

A movable double-hinge mechanism allows the door to "float" slightly. It can move horizontally and vertically with the furnace body's thermal expansion, ensuring the seal remains tight and secure at any temperature.

Ensuring Durability and Long-Term Performance

The extreme thermal cycling of a muffle furnace places immense stress on its components, especially the door.

The Critical Role of Water Cooling

The outer silicone seal, while excellent for airtightness, would quickly degrade from the radiant heat of the furnace.

A stainless steel water-cooling jacket is integrated into the door frame, circulating cool water. This actively removes heat from the sealing area, protecting the silicone ring and dramatically extending its service life.

Robust Construction Materials

The door and its components are built from durable materials like stainless steel. This provides the necessary structural integrity to withstand repeated use and resists the corrosion that can occur in lab environments.

Prioritizing Operator Safety and Usability

Modern furnace doors integrate features that protect the user and allow for process monitoring.

The Door Interlock Switch

This is a critical safety feature. An interlock switch automatically cuts power to the heating elements the moment the door is opened. This prevents user exposure to the dangerously high temperatures inside the chamber.

The Quartz Glass Observation Window

A small window, typically made of quartz glass due to its high thermal stability, is often built into the door. This allows operators to visually monitor the contents of the furnace without opening the door and disrupting the temperature and atmosphere.

Integrated Vent Ports

The door or furnace body often includes a vent port. This allows for the controlled release of gases produced during a process or can be used to introduce a specific atmosphere into the chamber.

Understanding the Trade-offs

While advanced door features improve performance, they come with certain considerations.

Complexity vs. Simplicity

A door with a water-cooling jacket, multi-point locks, and movable hinges offers superior performance. However, it also adds cost and maintenance points, such as managing water lines. Simpler designs are cheaper but provide inferior sealing and durability.

Seal Material Limitations

The dual-seal design is highly effective but relies entirely on the water-cooling system to function. A failure in the water circulation can lead to rapid degradation of the outer silicone seal, compromising the furnace's atmosphere.

Window Size vs. Heat Loss

While an observation window is useful, it is also a point of heat loss. A larger window offers a better view but can create a minor cold spot on the door's interior, slightly affecting temperature uniformity in that specific area.

Making the Right Choice for Your Application

Evaluating the door design is key to selecting the right furnace for your needs.

- If your primary focus is high-purity atmosphere control: Look for a door with dual seals, a multi-point lock, and a movable hinge to ensure the tightest seal possible.

- If your primary focus is high-temperature durability: Prioritize a furnace door with an integrated water-cooling jacket to protect the seals and ensure a long service life.

- If your primary focus is operational safety and ease of use: Ensure the door includes a power interlock switch and a clear observation window as non-negotiable features.

Understanding these design principles allows you to evaluate the quality and suitability of a furnace's most critical moving part.

Summary Table:

| Feature | Purpose | Key Components |

|---|---|---|

| Sealing System | Maintains internal atmosphere and prevents heat loss | Ceramic fiber rope (inner), silicone rubber ring (outer) |

| Locking Mechanism | Ensures even pressure for tight seal | Multi-point handwheel rotation |

| Hinge Design | Accommodates thermal expansion | Movable double-hinge mechanism |

| Water Cooling | Protects seals and extends lifespan | Stainless steel water-cooling jacket |

| Safety Features | Prevents operator exposure and allows monitoring | Interlock switch, quartz glass observation window, vent ports |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures precise alignment with your unique experimental requirements, delivering superior sealing, durability, and safety for optimal results. Contact us today to discuss how we can enhance your processes and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production