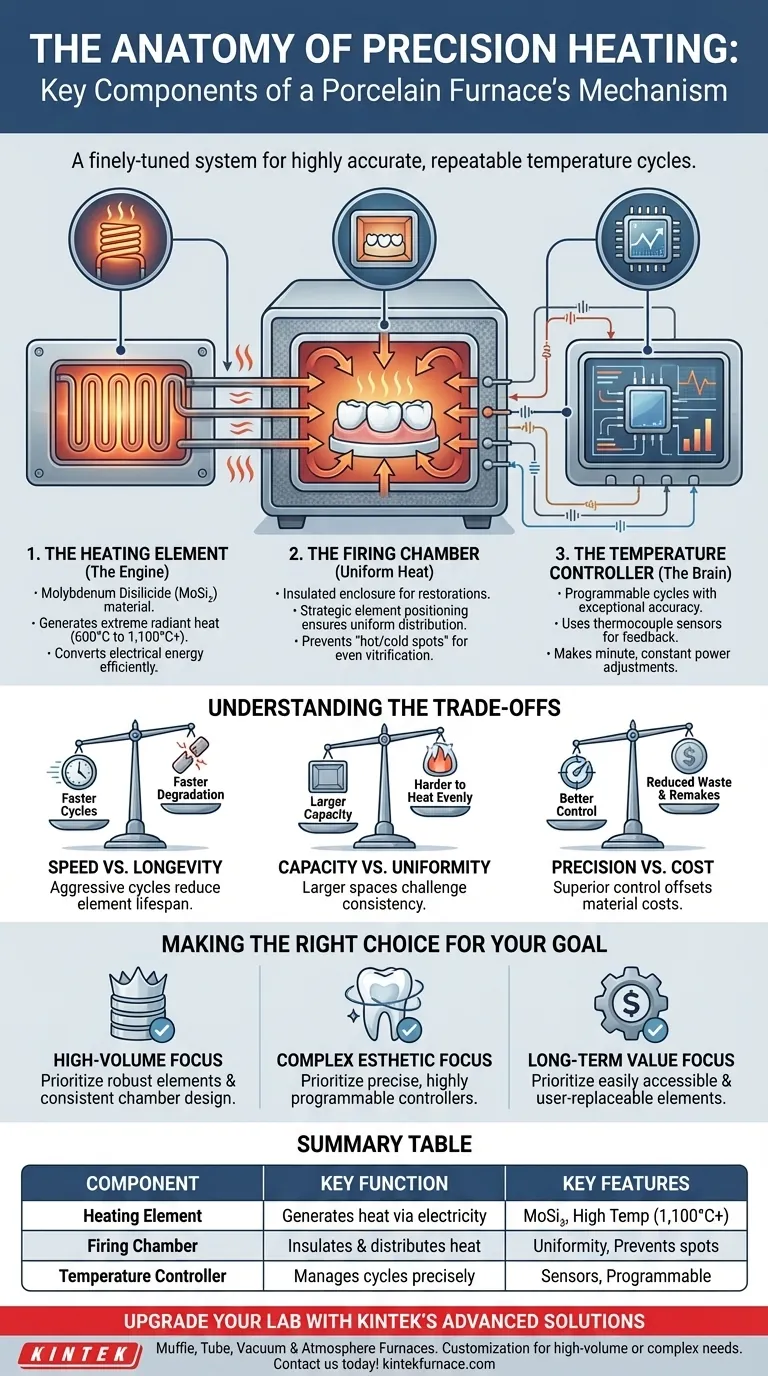

At its core, a porcelain furnace's heating mechanism is a finely-tuned system built from three essential parts. These are the heating elements that generate extreme temperatures, the insulated firing chamber that contains the heat, and the electronic temperature controller that masterfully directs the entire process. Together, they create a precisely controlled environment essential for firing dental ceramics.

The ultimate goal of the furnace's heating system is not simply to get hot, but to execute a highly accurate and repeatable temperature cycle. The quality of your final ceramic restoration depends directly on the synergy between the power of the heating element, the design of the chamber, and the intelligence of the controller.

The Anatomy of Precision Heating

To understand how a furnace achieves reliable results, we must look at how each core component contributes to the overall function. This is not just a collection of parts; it is an integrated system where each piece has a critical role.

The Heating Element: The Engine of the Furnace

The heating element is the component responsible for converting electrical energy into radiant heat. These are the workhorses that bring the furnace chamber up to the required temperatures, often ranging from 600°C to over 1,100°C.

Most modern furnaces use elements made from robust materials like molybdenum disilicide, which are capable of withstanding thousands of high-temperature cycles without degrading quickly.

The Firing Chamber: Ensuring Uniform Heat

The firing chamber is the insulated enclosure that holds the dental restorations during the firing cycle. Its design is critical for achieving consistent results.

The heating elements are strategically positioned—often above, below, and around the work—to ensure uniform heat distribution. This prevents "hot spots" and "cold spots," which could cause uneven vitrification or cracks in the porcelain.

The Temperature Controller: The Brains of the Operation

The temperature controller is the electronic brain that governs the entire heating process. It dictates the rate of temperature increase, how long the temperature is held (the "soak"), and the cooling rate.

Using feedback from temperature sensors (like thermocouples) within the chamber, the controller makes constant, minute adjustments to the power sent to the heating elements. This allows for the execution of complex, programmable firing cycles with exceptional accuracy, which is essential for modern, sensitive ceramic materials.

Understanding the Trade-offs

Choosing or operating a furnace involves balancing competing factors. Understanding these trade-offs is key to managing costs and ensuring quality.

Element Longevity vs. Cycle Speed

Heating elements have a finite lifespan. Running consistently aggressive, rapid-fire heating and cooling cycles will achieve a faster turnaround but will also degrade the elements more quickly, leading to more frequent and costly replacement.

Chamber Capacity vs. Heat Uniformity

A larger firing chamber can process more restorations at once, increasing throughput. However, larger spaces are inherently more challenging to heat evenly, increasing the risk of inconsistent firing if the furnace design is not optimized.

Control Precision vs. Material Cost

Advanced ceramic systems have very specific and often unforgiving firing parameters. Using a furnace with a less precise temperature controller might seem like a cost-saving measure, but it can lead to failed restorations and the waste of expensive materials. The cost of a superior controller is often offset by the reduction in remakes.

Making the Right Choice for Your Goal

Your specific needs should dictate what aspects of the heating system you prioritize.

- If your primary focus is high-volume, standard crowns: Look for a furnace with a reputation for robust, long-lasting heating elements and a chamber design proven to deliver consistent results across its entire area.

- If your primary focus is complex, esthetic restorations: Prioritize a furnace with an exceptionally precise and highly programmable temperature controller to perfectly match the strict protocols of advanced ceramic materials.

- If your primary focus is maximizing long-term value: Choose a model with easily accessible and user-replaceable heating elements to minimize downtime and technician service costs.

Understanding how these components function together empowers you to move from simply running a cycle to truly controlling the outcome of your ceramic work.

Summary Table:

| Component | Key Function | Key Features |

|---|---|---|

| Heating Element | Generates heat via electrical energy | Made of molybdenum disilicide, withstands high temperatures (600°C to 1,100°C+) |

| Firing Chamber | Insulates and distributes heat uniformly | Prevents hot/cold spots, ensures even vitrification |

| Temperature Controller | Manages heating cycles with precision | Uses sensors like thermocouples, programmable for accuracy |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, whether for high-volume crowns or complex esthetic restorations. Contact us today to enhance efficiency and achieve superior ceramic results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time