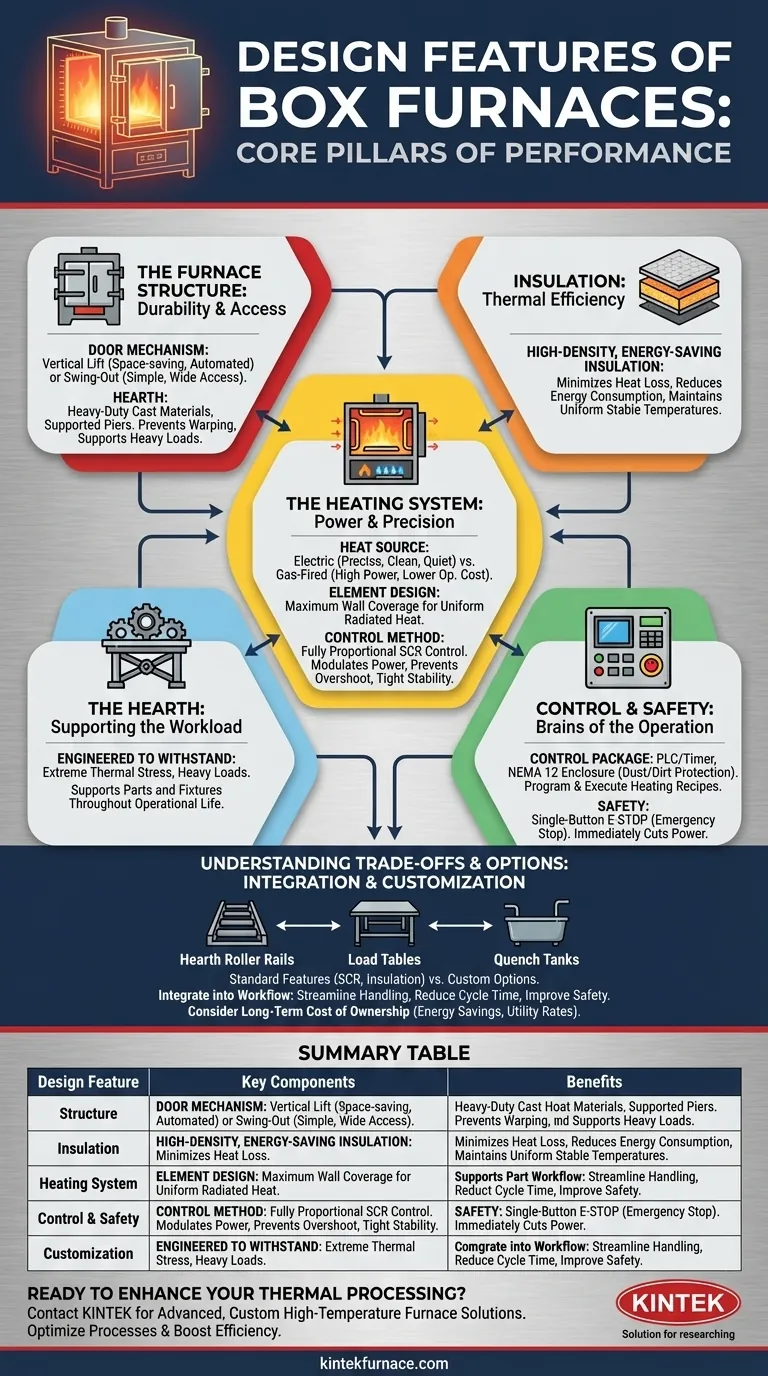

At their core, box furnaces are engineered around five fundamental design pillars. These include the physical structure for access and durability, the insulation for thermal efficiency, the heating system for power and uniformity, the hearth for load support, and the control system for precision and safety. While many configurations exist, these core components define the furnace's capabilities and performance in any industrial setting.

While the list of features appears straightforward, the true design challenge lies in balancing durability, temperature uniformity, and operational efficiency. Each component, from the door mechanism to the control system, represents a critical decision that directly impacts the furnace's suitability for a specific heat-treating application.

The Furnace Structure: Durability and Access

The physical construction of a box furnace dictates its lifespan, ease of use, and ability to integrate into a production line.

Door Mechanism: The Gateway to Your Process

The door is the most frequently used component. The two primary designs are vertical lift and swing-out.

Vertical lift doors are ideal for conserving floor space and are often preferred for automated loading and unloading processes. Swing-out doors are mechanically simpler and can provide wider, unobstructed access to the chamber.

Insulation: The Key to Thermal Efficiency

Modern furnaces use high-density, energy-saving insulation. This is not merely a cost-saving feature; it is critical for performance.

Superior insulation minimizes heat loss to the surrounding environment, which directly reduces energy consumption. More importantly, it helps maintain stable and uniform temperatures within the chamber, a crucial factor for consistent process results.

The Hearth: Supporting the Workload

The furnace floor, or hearth, is designed to withstand extreme thermal stress and heavy loads. It is typically constructed from heavy-duty cast materials and supported by robust piers.

This construction prevents warping, cracking, or sagging over thousands of thermal cycles, ensuring a stable platform for parts and fixtures throughout the furnace's operational life.

The Heating System: Power and Precision

The heating system is the heart of the furnace, responsible for delivering thermal energy accurately and uniformly.

Heat Source: Gas vs. Electric

Box furnaces can be heated by fully proportional gas or electric systems.

Electric furnaces, which use heating elements, offer exceptional temperature precision, a clean operating environment, and quiet operation. Gas-fired furnaces can often deliver more power for a lower operational cost (depending on utility prices) and are excellent for larger chambers.

Element Design: Ensuring Uniform Temperature

In electric furnaces, the placement of heating elements is critical. The goal is to achieve maximum wall coverage to radiate heat evenly throughout the chamber.

Poor element design creates hot and cold spots, leading to inconsistent metallurgical properties in the processed parts. A well-designed system ensures every part in the workload receives the same thermal treatment.

Control Method: Proportional and SCR Control

The term "fully proportional" control is key. Unlike a simple on/off thermostat, this system continuously modulates the power output.

This is often achieved using a Silicon-Controlled Rectifier (SCR), which finely adjusts the voltage to the heating elements. This method prevents temperature overshooting and provides the tight stability required for sensitive thermal processes.

Control and Safety: The Brains of the Operation

The control system governs every aspect of the furnace's operation, ensuring repeatability, safety, and integration.

The Control Package: Repeatability and Oversight

A state-of-the-art control package typically includes a multi-function electronic timer or a programmable logic controller (PLC). These systems allow operators to program, save, and execute complex heating recipes with high repeatability.

These components are housed in a NEMA 12 control panel, which is an industrial enclosure designed to protect sensitive electronics from dust, dirt, and dripping non-corrosive liquids.

Safety Mechanisms: Protecting Personnel and Equipment

Safety is paramount in high-temperature equipment. A single-button E-stop (Emergency Stop) is a standard, non-negotiable feature that immediately cuts power to the heating system in an emergency.

Understanding the Trade-offs and Options

A standard box furnace provides a functional baseline, but its true value is realized through customization for a specific workflow.

Standard Features vs. Custom Options

The standard specifications—like SCR control and high-density insulation—form the foundation of a quality furnace. However, optional features are what tailor the machine to your process.

Integrating the Furnace into Your Workflow

Options like hearth roller rails, load tables, and adjacent quench tanks are not accessories; they are system components.

These additions transform a standalone furnace into an integrated heat-treat cell, streamlining material handling, reducing cycle time, and improving operator safety and ergonomics.

The True Cost of Ownership

When selecting features, consider the long-term implications. Upgrading insulation may increase the initial price but can pay for itself in energy savings. Choosing between gas and electric has a profound impact on monthly utility costs.

Making the Right Choice for Your Goal

Selecting the right features depends entirely on your operational priorities.

- If your primary focus is process precision and repeatability: Scrutinize the control package, the use of SCR power control, and the heating element layout for maximum uniformity.

- If your primary focus is high-volume production and automation: Prioritize a vertical lift door and integration options like hearth roller rails and automated load tables.

- If your primary focus is minimizing long-term operating costs: Invest in the highest quality insulation and carefully analyze the cost-benefit of gas versus electric heating based on your local utility rates.

Understanding these design principles empowers you to select not just a furnace, but a tailored solution for your specific thermal processing needs.

Summary Table:

| Design Feature | Key Components | Benefits |

|---|---|---|

| Structure | Vertical lift or swing-out doors, heavy-duty hearth | Durability, easy access, stable load support |

| Insulation | High-density materials | Energy efficiency, uniform temperature, reduced heat loss |

| Heating System | Electric or gas elements, SCR control | Precise temperature, power options, consistent results |

| Control & Safety | PLC, NEMA 12 panel, E-stop | Repeatability, safety, integration with workflows |

| Customization | Roller rails, load tables, quench tanks | Enhanced automation, reduced cycle time, ergonomic handling |

Ready to enhance your thermal processing with a custom box furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions for diverse laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your heat treatment processes and boost efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab