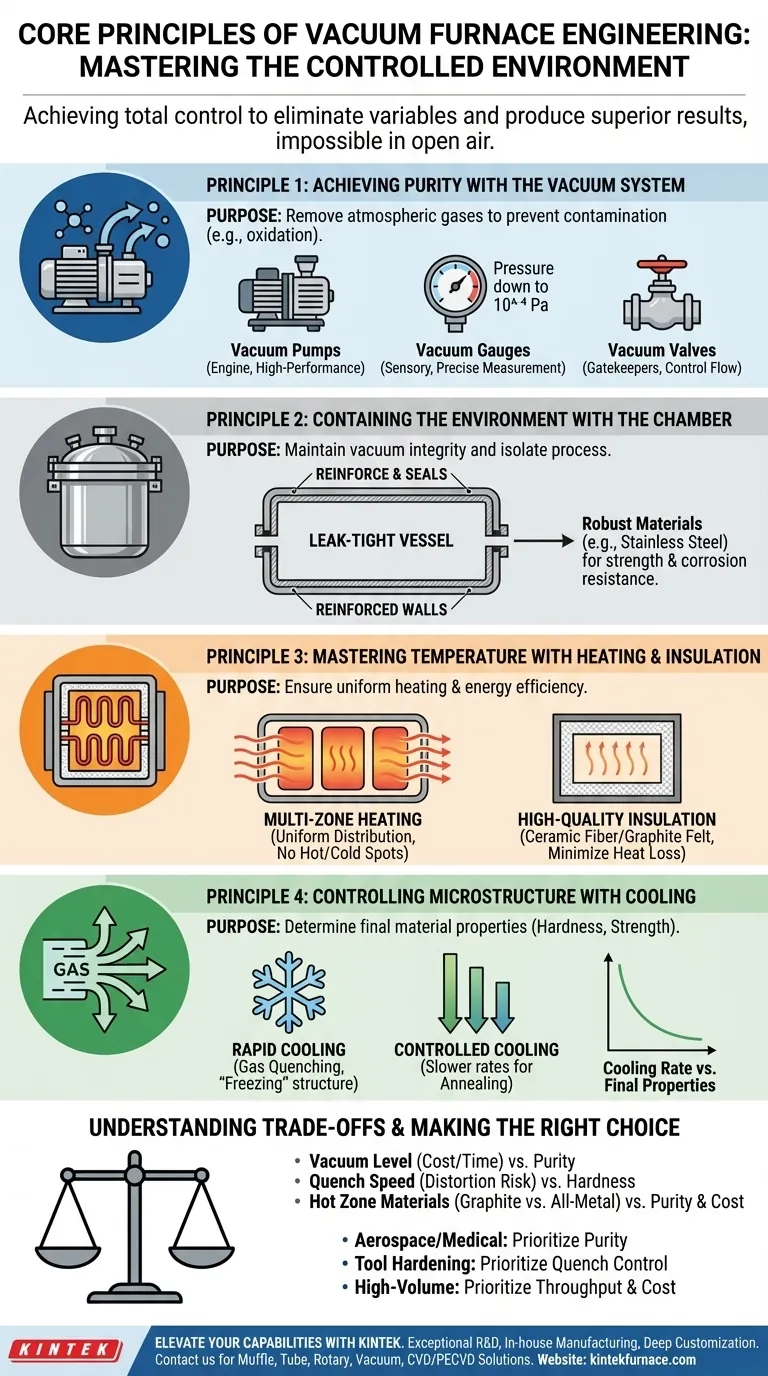

At its core, vacuum furnace engineering is the science of creating an immaculately controlled environment. It operates on four key principles: achieving a high-purity vacuum, containing that environment within a leak-tight chamber, precisely managing temperature with uniform heating and insulation, and controlling the material’s final properties through managed cooling. This combination allows for metallurgical processes that are impossible in open air.

The fundamental goal of a vacuum furnace is not simply to remove air. It is to achieve total and repeatable control over a material's environment, thereby eliminating variables like oxidation and contamination to produce superior, predictable results.

Principle 1: Achieving Purity with the Vacuum System

The vacuum system is the heart of the furnace, responsible for creating the pristine conditions required for advanced thermal processing. Its function is to remove atmospheric gases that would otherwise react with the material at high temperatures.

The Role of Vacuum Pumps

High-performance vacuum pumps are the engine of the system. They physically remove air and other gases from the sealed chamber to reduce the internal pressure.

The level of vacuum is critical, with modern furnaces capable of reaching pressures as low as 10-4 Pa, effectively eliminating almost all atmospheric molecules.

The Importance of Measurement

A process is only as good as its ability to be measured. Vacuum gauges are the sensory organs of the furnace, providing precise, real-time data on the pressure inside the chamber.

This measurement confirms that the required level of purity has been reached before the heating cycle begins, ensuring process repeatability.

The Necessity of Control

Vacuum valves act as the gatekeepers of the system. They isolate the chamber, control the flow of gases, and regulate the pump-down sequence.

Proper valve control is essential for managing the process, from initial evacuation to the backfilling of inert gas during the cooling phase.

Principle 2: Containing the Environment with the Chamber

The vacuum chamber, or vessel, is the physical barrier that contains the controlled environment. Its integrity is non-negotiable for successful operation.

The Foundation of a Leak-Tight Vessel

The primary design principle for the chamber is that it must be leak-tight. Any leak, no matter how small, compromises the vacuum by allowing atmospheric gases to enter, defeating the purpose of the furnace.

Chambers are typically constructed from robust materials like stainless steel, which offers strength and resistance to corrosion, ensuring a long operational life.

Principle 3: Mastering Temperature with Heating and Insulation

Once the vacuum is established, the furnace's purpose is to apply heat. This must be done with exceptional uniformity and efficiency.

Uniform Heating for Consistent Results

Heating elements are strategically placed in multiple zones throughout the chamber. This multi-zone configuration allows for independent control over different areas.

The result is highly uniform temperature distribution across the entire workload, preventing hot or cold spots and ensuring every part receives the exact same thermal treatment.

Minimizing Heat Loss with Insulation

High-quality insulation is crucial for both efficiency and control. It lines the chamber walls, reflecting heat back toward the workload and preventing it from escaping.

This not only reduces energy consumption but also protects the chamber walls and helps maintain stable, uniform temperatures. Materials often include ceramic fiber or specialized graphite felt.

Principle 4: Controlling Microstructure with Cooling

The cooling phase is just as critical as the heating phase. The rate at which a material cools determines its final microstructure and, therefore, its mechanical properties like hardness and strength.

Rapid Cooling with Gas Quenching

For processes like hardening, rapid cooling is required. This is achieved through gas quenching, where a high-pressure, inert gas (like nitrogen or argon) is forcefully circulated through the chamber.

This process quickly extracts heat from the parts, "freezing" the desired metallurgical structure in place without the risk of oxidation.

Precision with Controlled Cooling Rates

For other processes like annealing or stress relieving, a slower, more controlled cooling rate is needed. This can be achieved by simply letting the furnace cool down naturally or by introducing a slow, controlled flow of inert gas.

This precise control over the cooling rate is a key advantage of vacuum furnaces, enabling a wide range of metallurgical outcomes.

Understanding the Trade-offs and Limitations

While powerful, vacuum furnace engineering involves balancing competing factors. Understanding these trade-offs is key to optimizing any process.

Vacuum Level vs. Cost and Time

A deeper vacuum provides higher purity, but it comes at a cost. Achieving ultra-high vacuum levels requires more powerful (and expensive) pumps and significantly longer pump-down times, which reduces throughput. For many applications, a moderate vacuum is entirely sufficient.

Quench Speed vs. Part Distortion

Aggressive gas quenching is excellent for achieving maximum hardness, but the rapid temperature change can introduce thermal stress. This stress can lead to distortion or even cracking in complex or thin-walled parts. The quench rate must be carefully balanced with the geometry of the part.

Hot Zone Materials: Purity vs. Durability

The choice of "hot zone" materials (heating elements and insulation) is a critical trade-off. Graphite-based systems are durable and cost-effective but can be a source of carbon contamination for certain sensitive alloys. All-metal hot zones (molybdenum or tungsten) offer extreme purity but are more expensive and can be more fragile.

Making the Right Choice for Your Goal

Your application dictates which engineering principles to prioritize.

- If your primary focus is maximum purity for sensitive materials (aerospace, medical): Prioritize a high-performance vacuum system and an all-metal hot zone to eliminate any risk of contamination.

- If your primary focus is achieving specific mechanical properties (tool hardening): Prioritize precise control over the heating uniformity and, most importantly, the gas quenching system's speed and pressure.

- If your primary focus is high-volume, general-purpose heat treating: Prioritize a balance between a sufficient vacuum level, rapid cycle times, and the durability of a graphite-based hot zone to maximize throughput and cost-efficiency.

By understanding these core principles, you can move beyond simply using a vacuum furnace to truly mastering the process for your specific needs.

Summary Table:

| Principle | Key Components | Purpose |

|---|---|---|

| Achieving Purity | Vacuum pumps, gauges, valves | Remove atmospheric gases to prevent contamination |

| Containing Environment | Leak-tight chamber (e.g., stainless steel) | Maintain vacuum integrity and isolate process |

| Mastering Temperature | Multi-zone heating, high-quality insulation | Ensure uniform heating and energy efficiency |

| Controlling Microstructure | Gas quenching, controlled cooling rates | Determine final material properties like hardness |

Ready to elevate your laboratory's capabilities with precision-engineered vacuum furnaces? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether you're in aerospace, medical, tool hardening, or high-volume heat treating. Contact us today to discuss how our tailored furnace solutions can deliver superior purity, control, and efficiency for your specific goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance