In a vacuum furnace, quenching is achieved primarily through two methods: high-pressure gas quenching and oil quenching. The choice between them is dictated by the specific material being heat-treated and the required cooling rate needed to achieve the desired metallurgical properties, such as hardness and microstructure.

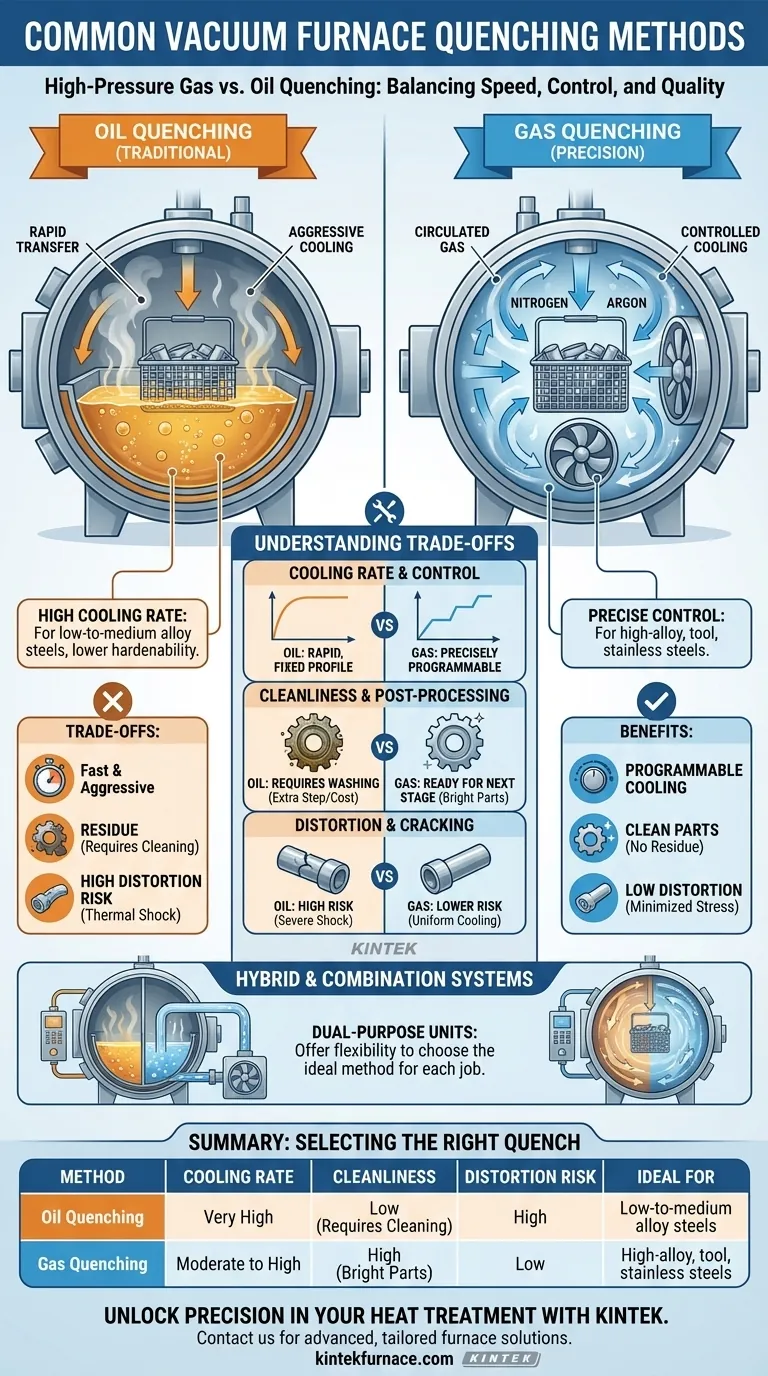

The fundamental decision in vacuum furnace quenching is a trade-off between speed and control. Oil quenching offers the highest cooling rates for less hardenable alloys, while gas quenching provides superior cleanliness, reduced distortion, and precise process control for more sensitive, high-alloy materials.

The Two Primary Quenching Methods Explained

Understanding the mechanics and applications of gas and oil quenching is crucial for any heat treatment process. Each method interacts with the material differently, producing distinct outcomes.

Oil Quenching: The Traditional Approach

Oil quenching involves rapidly transferring the heated workload from the vacuum furnace's hot zone into an integrated, sealed oil bath. This submersion provides an extremely fast and aggressive cooling rate.

This method is essential for certain low-to-medium alloy steels that possess lower hardenability. These materials require a very rapid quench to transform their microstructure correctly and achieve full hardness.

Gas Quenching: Precision and Cleanliness

Gas quenching uses a high-purity inert gas, most commonly Nitrogen or Argon, to cool the workload. The gas is introduced into the hot zone and circulated at high velocity by a powerful fan, with cooling rates controlled by the gas pressure.

Pressures can range from sub-atmospheric levels for very slow cooling up to 25 bar for High-Pressure Gas Quenching (HPGQ). This method is ideal for materials like high-speed tool steels, die steels, and stainless steels, which are sensitive to thermal shock but have sufficient hardenability to be cooled effectively with gas.

Understanding the Trade-offs

Selecting a quenching method is not just about its primary function; it involves balancing competing factors like part integrity, post-processing requirements, and operational costs.

Cooling Rate vs. Control

Oil provides a very rapid quench, but its cooling profile is largely fixed. It is difficult to modify the cooling rate mid-process.

Gas quenching offers exceptional control. By adjusting the gas pressure and fan speed, the cooling rate can be precisely programmed and even varied during the cycle to optimize metallurgical results and minimize stress.

Part Cleanliness and Post-Processing

Parts quenched in oil will have an oil residue that must be removed through a subsequent washing or cleaning process. This adds an extra step and cost to production.

Gas quenching produces exceptionally clean and bright parts that are often ready for the next manufacturing stage without any cleaning.

Distortion and Cracking Risk

The severe thermal shock from oil quenching increases the risk of part distortion, warping, or even cracking, especially in components with complex geometries or thin sections.

The more uniform and controlled cooling of a gas quench significantly minimizes thermal stress, leading to greater dimensional stability and a lower risk of scrapped parts.

Hybrid and Combination Systems

To provide maximum flexibility, some vacuum furnaces are designed as dual-purpose systems. These units contain both an integral oil bath and a high-pressure gas quenching system, allowing the operator to choose the ideal method for each specific job.

Another variation involves quenching with 2-5 bar of gas pressure over the surface of an oil bath, which can help suppress oil vapors and modify the cooling characteristics.

Selecting the Right Quench for Your Application

The optimal quenching method is always the one that achieves the target metallurgical properties without compromising the integrity of the component.

- If your primary focus is maximum hardness for lower-alloy steels: Oil quenching is often the necessary choice due to its unmatched cooling speed.

- If your primary focus is minimizing distortion and ensuring part cleanliness: High-pressure gas quenching is the superior method, especially for high-alloy, tool, and stainless steels.

- If your primary focus is process flexibility for a wide variety of materials: A dual-chamber furnace with both oil and gas quenching capabilities offers the most versatile solution.

Ultimately, matching the quenching method to the material's specific transformation requirements is the key to successful vacuum heat treatment.

Summary Table:

| Method | Cooling Rate | Cleanliness | Distortion Risk | Ideal For |

|---|---|---|---|---|

| Oil Quenching | Very High | Low (requires cleaning) | High | Low-to-medium alloy steels |

| Gas Quenching | Moderate to High | High (bright parts) | Low | High-alloy, tool, stainless steels |

Unlock Precision in Your Heat Treatment with KINTEK

Struggling to choose the right quenching method for your materials? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're working with low-alloy steels requiring oil quenching or high-alloy materials needing gas quenching, we ensure optimal cooling rates, reduced distortion, and superior cleanliness.

Contact us today via our contact form to discuss how our furnaces can enhance your lab's efficiency and achieve your metallurgical goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety